Barranca Diamond FIREBALL 2 AXLE SPHERE MACHINE User Manual

Page 11

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

11

SPHERE POLISHING

The sphere grinding phase will require the most attention as it is the users inspection of the material and

shape that determines if the sphere is ground to his or her satisfaction. On soft materials (i.e. travertine,

serpentine, fluorite, etc.) the time to “rough out" or grind the preformed block into a sphere shape is

significantly less than the time to grind out a sphere of hard and dense lapidary materials such as jasper,

jade, agate, quartz, etc. Therefore, experience from trial and error will dictate how much time the user must

devote to rough sphere grinding. High grinding velocities do not necessarily yield shorter rough sphere

grinding time. The user will have to closely monitor the sphere block during course grinding to determine if a

sphere has been obtained.

Once the sphere material is ground to the user’s satisfaction and the cups are changed to the Velcro lined

resin pad holder cups, the first diamond resin pad that should be placed in the holder cup is dependent on

the severity of scratches and marks that need to be removed from the material and its relative hardness. For

example, a soft material like travertine can be rapidly polished to remove scratches from the grinding cups

using a 120 and or 220 grit pad wedges. Harder materials like agate and jasper require more aggressive pads

(i.e. 30 or 50 grit) to remove stubborn grinding phase scratches and high spots.

Once the stubborn scratches are removed with the resin diamond wedges in the Velcro lined holder cups

in the 30 to 220 grit range, the final sequence of polishing to a high mirror like finish will be performed in

the diamond grit range of 400, 800, 1800, 3500, 8500, and 13,000 mesh resin diamond wedges. An even

higher final finish can be obtained with cerium, aluminum, or tin oxide polishing compounds if felt wedges (not

included with machine) are used. For most lapidary material the use of the 13,000 grit diamond pads will yield

a satisfactory polish.

FINAL TIPS ON USE OF DIAMOND RESIN WEDGES FOR POLISHING

The following tips should be adhered to by the user to obtain the highest mirror polish on the sphere material:

1) Rinse and clean each diamond resin wedge with a tooth brush and clean water after each use. Be sure to

dry pads after cleaning and store in a sealable plastic bag.

2.) Do not reuse water from collection pan. Only pump clean water to nozzle from a 5 gallon bucket.

3) Rinse clean completely the slurry catch plastic pan after each grit size change. The pad holder cups

should be cleaned as well between pads with a toothbrush and clean water.

4) Ensure resin diamond wedges are placed securely inside the holder cups and that the Velcro is in good

condition and affixed securely to the cast iron inside of the cups to prevent the pads from shifting or falling

out during polishing. Periodically, the user will have to remove the Velcro strips and replace with new

Velcro strips (super glue epoxy is recommended to hold the Velcro strips securely).

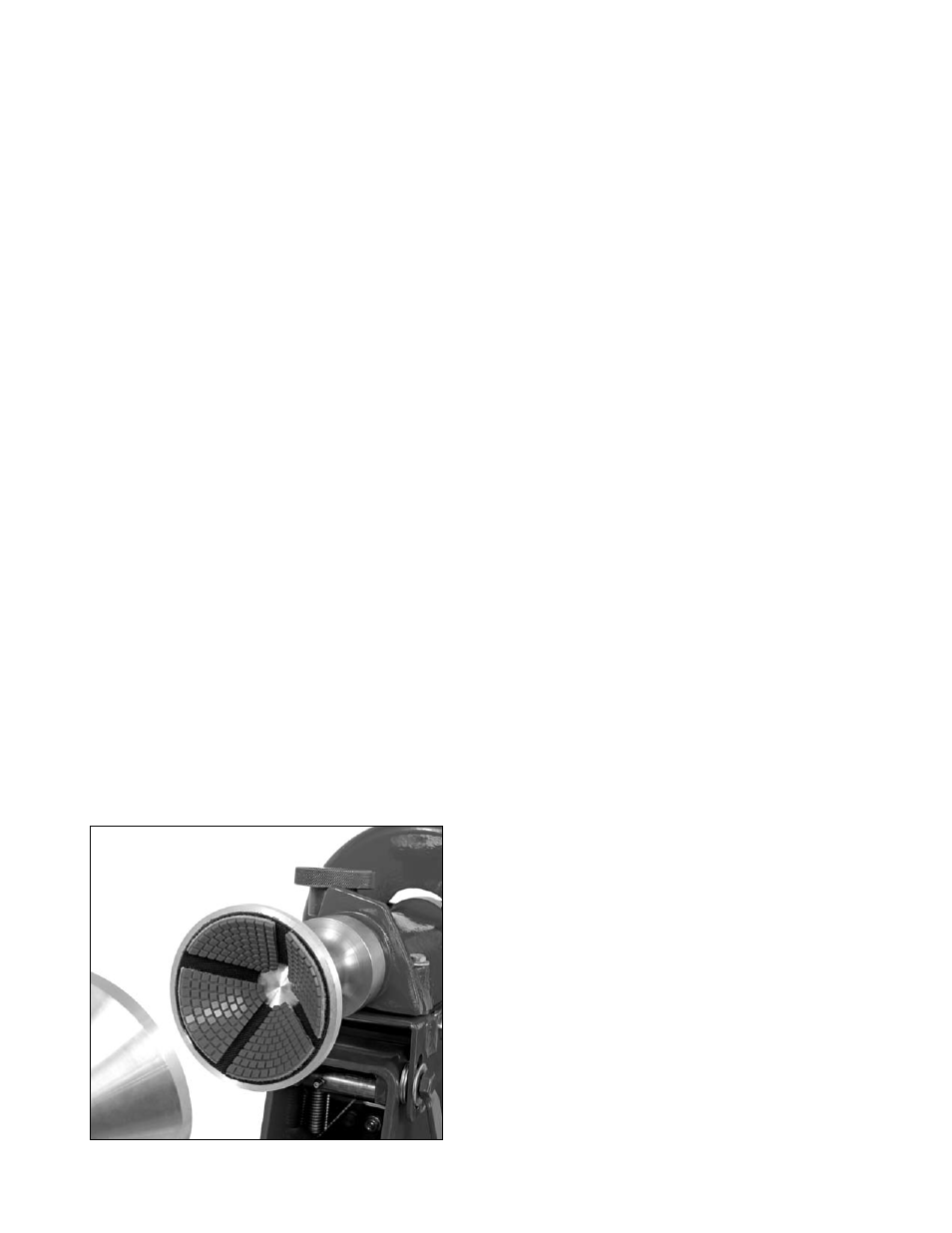

Velcro pad holder cup