Installation instructions, Caution – Autoquip TRUCK LEVELER - SHALLOW PIT MOUNT User Manual

Page 27

27

POWER UNIT

1. The power unit is to be located in an area protected from the elements and should

be installed prior to the lift to so that it may be operated during the installation of the

platform. The recommended location is inside the building.

2. The power unit can be mounted on the floor or wall with the wall mount brackets. Do

not install outside unless a weatherproof cover has been furnished or otherwise

protected from the elements.

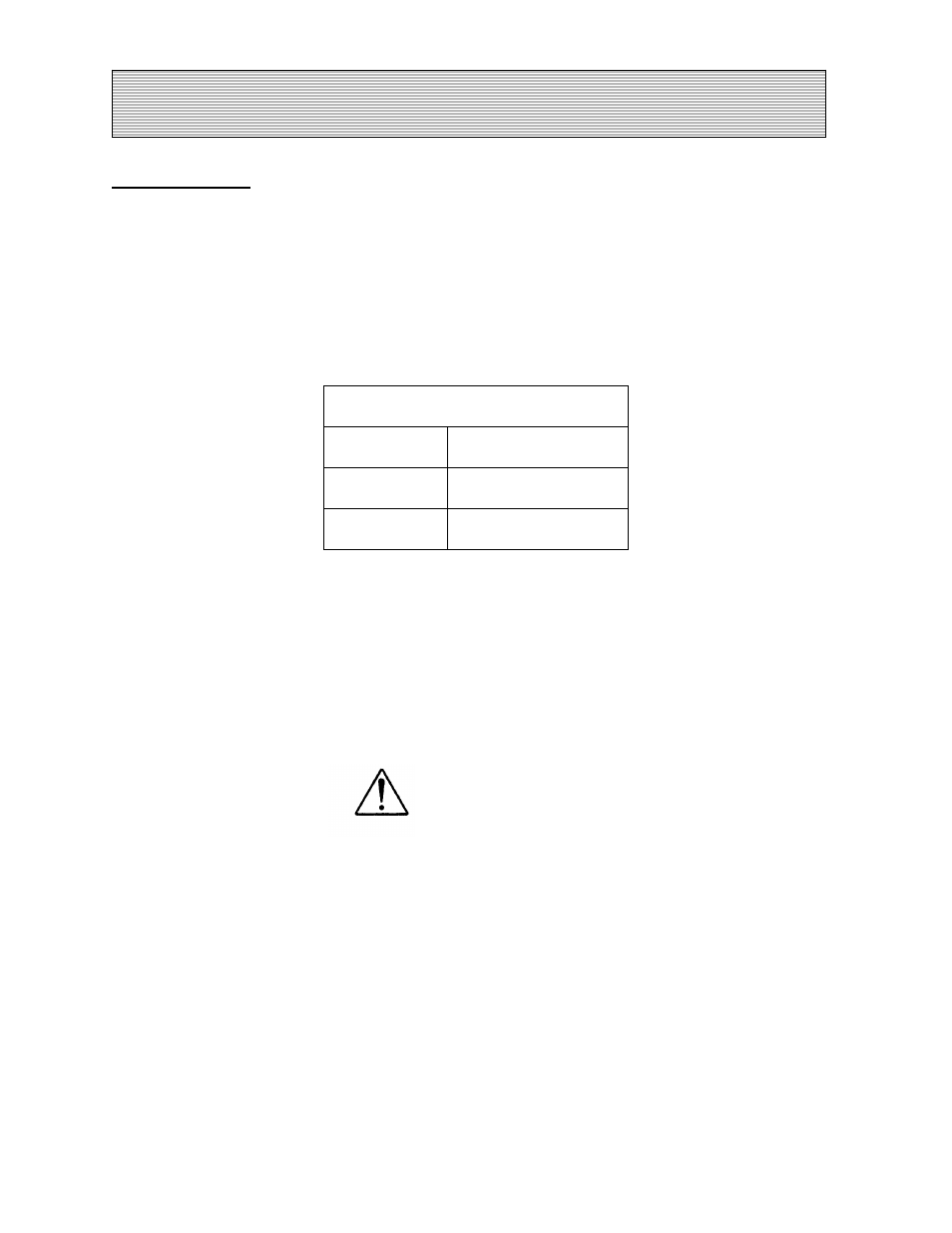

Hydraulic Piping/Hose Size

Up to 25 feet 1/2" inside diameter

26 – 50 feet

3/4" inside diameter

Over 50 feet

1” inside diameter

NOTE: the pipe must be schedule 80 with extra heavy fittings. All hoses, fittings,

and pipe are to have a minimum rated operating or working pressure of 3,000

PSI.

3. The electrical work is to be done in accordance with local codes by a qualified

control electrician. See “Standard Wiring Diagrams” in the Maintenance section of

this manual for proper electrical installation. All wiring must meet current NEC

(National Electric Code).

CAUTION!

Precaution should be taken to prevent the introduction of contaminates

such as dirt or other foreign material into the system through open fittings,

pipes, or disassembled components. Contamination will ruin the hydraulic

system.

Do not run the motor more than a few short bumps to check rotation if

there is no oil in the reservoir. The pump may become damaged. If the

reservoir contains oil, precautions should be taken to collect pumped oil to

prevent spillage.

4. Check the rotation of the motor. Correct rotation is clockwise when viewing the

motor shaft from under the dust cap on the end bell housing. Replace the dust cap

when the check is complete.

INSTALLATION INSTRUCTIONS