General maintenance – Autoquip SERIES 35 LOW PROFILE User Manual

Page 35

WIRING AUTOQUIP "SUPER TORQUE' MOTORS

Because Autoquip "Super-Torque" motors actually deliver substantially more

horsepower than their nameplate rating, they must always be wired for heavier current-

draw than standard motors of the same nameplate rating. However, because of the

"Super-Torque" motors starting efficiency and superior running characteristics, circuit

components do not have to be as large as for standard motors of equal delivered

horsepower.

The following chart should be observed in connecting these motors to power

sources, remembering that, where 115-Volt operation is contemplated, the current-

draw is too heavy for plugging into ordinary lighting circuits. Heavy wire must be

used all the way to the power-source.

NOTE: For larger horsepower motors, consult factory.

HP and Voltage

Full Load Amperages

1/2 HP: 115 V /60 CY/1 PH (36S15)

115 Volts = 15.0 Amps

3/4 HP: 115 V /60 CY/1 PH

115 Volts = 16.6 Amps

3/4 HP: 230 V /60 CY/1 PH

230 Volts = 8.3 Amps

3 HP: 115 / 208 / 230V /60 CY/1PH

Vertical Motor (Not Super Torque)

115 V = 33.6 Amps

208/230V=16.8 Amps

5 HP: 230 V /60 CY/1 PH

Vertical Motor (Not Super Torque)

230 Volts = 23.0 Amps

1-1/2 HP: 208 / 230 V /60 CY/3 PH

208 / 230 V= 5.3 Amps

1-1/2 HP: 460 V /60 CY/ 3 PH

460Volts = 2.85 Amps

5 HP: 208 / 230 V /60 CY/3 PH

Contractor Motor

208 V=15.8 Amps

230 V=14.8 Amps

5 HP: 460 V /60 CY/3 PH

Contractor Motor

460 Volts = 7.4 Amps

5 HP: 208 / 230 V /60 CY/3 PH

Vertical Motor

208 V=16 Amps

230 V=15.2 Amps

5 HP: 460 V /60 CY/3 PH

Vertical Motor

460 V=7.6 Amps

GENERAL MAINTENANCE

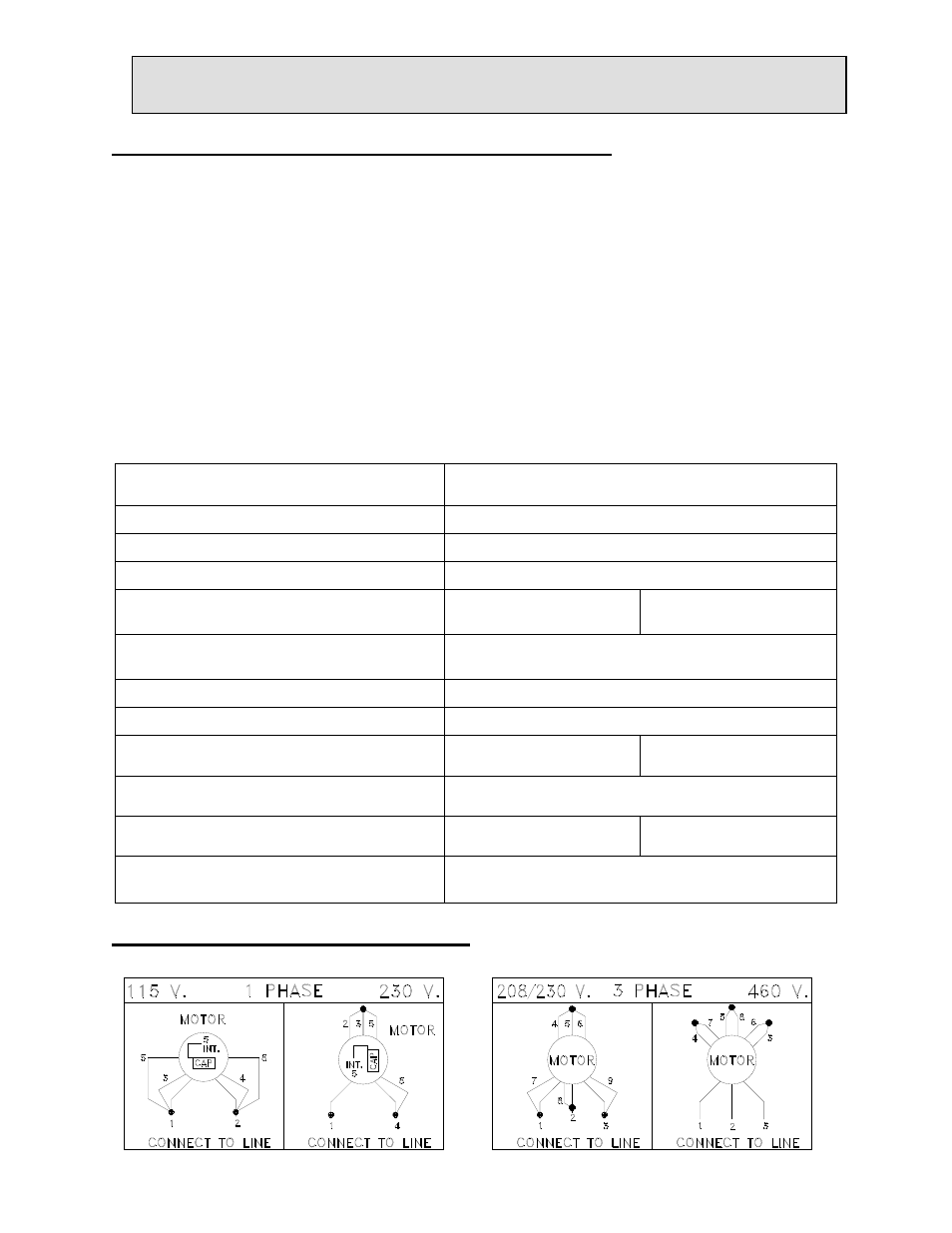

MOTOR CONNECTION DIAGRAMS

35