Routine maintenance – Autoquip SERIES 35 LOW PROFILE User Manual

Page 30

ROUTINE MAINTENANCE

Annual Inspection (1000 hours of operation):

• Change hydraulic fluid and clean reservoir as needed. Always use clean fluid.

Never return fluid from drip pans, pit, etc. back to reservoir. Dispose of and handle

used fluid as a hazardous material.

• If noise or vibration has been noticed, remove lift cylinder pins, pivot pins, and

roller bearings. Inspect for wear and replace as necessary.

• Inspect all hydraulic hoses, replace any that show signs of chafing or leaking.

• Replace suction filter.

• Check for permanent mechanical deformation.

OIL RECOMMENDATIONS

Hydraulic lifts operate efficiently utilizing high quality oil products that are readily

available in all areas. These oil products contain additives that are desirable for

optimum performance of the equipment. Follow the recommendations below that apply

to the circumstances most similar to your installation.

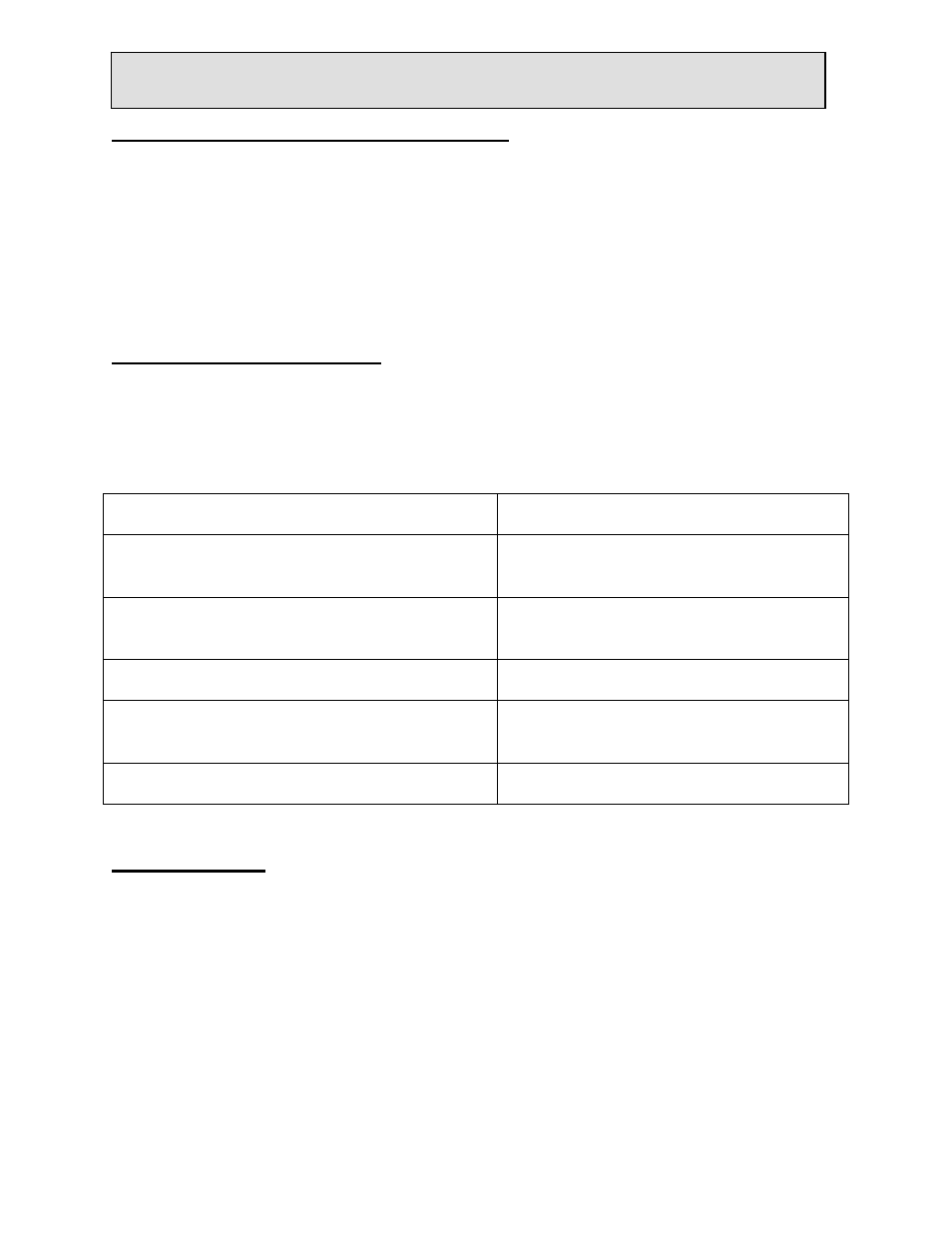

Environment (Ambient Temperature)

Recommended Oil

Indoor locations with variable temperatures:

30 - 100 degrees F

5W 30 or 5W 40 Multiviscosity Motor Oil

Indoor locations with constant temperatures:

60 - 80 degrees F

Permissible to use SAE 20 Motor Oil

Outdoor locations: 30 - 120 degrees F

5W 30 or 5W 40 Multiviscosity Motor Oil

Outdoor locations: 10 degrees F below 0 to

100 degrees F

5W 20 or 5W 30 Multiviscosity Motor Oil

Cold Storage Warehouse: 10 - 40 degrees F

Contact local Autoquip Service Rep.

NOTE: All oils above are detergent type.

OIL CAPACITY

Standard Series 35 Polyethylene Tank: Oil capacity is approximately 1.25 gallons or (5) quarts.

Series 35: 48S80 & 9S60 Tube Tank: Oil capacity is approximately 2.0 gallons or (8) quarts.

Contractor polyethylene Tank: Oil capacity is approximately: (5.5) gallons or (22) quarts.

Vertical Steel Tank: Oil capacity is approximately: (10) gallons or (40) quarts.

30