2 shimming and anchoring lift to concrete, 3 remote power unit installation, 4 power unit wiring – Autoquip TITAN SCISSOR LIFT TABLE User Manual

Page 17: 1 intermittent remote power unit, Shimming and anchoring lift to concrete, Remote power unit installation, Power unit wiring, Intermittent remote power unit

17

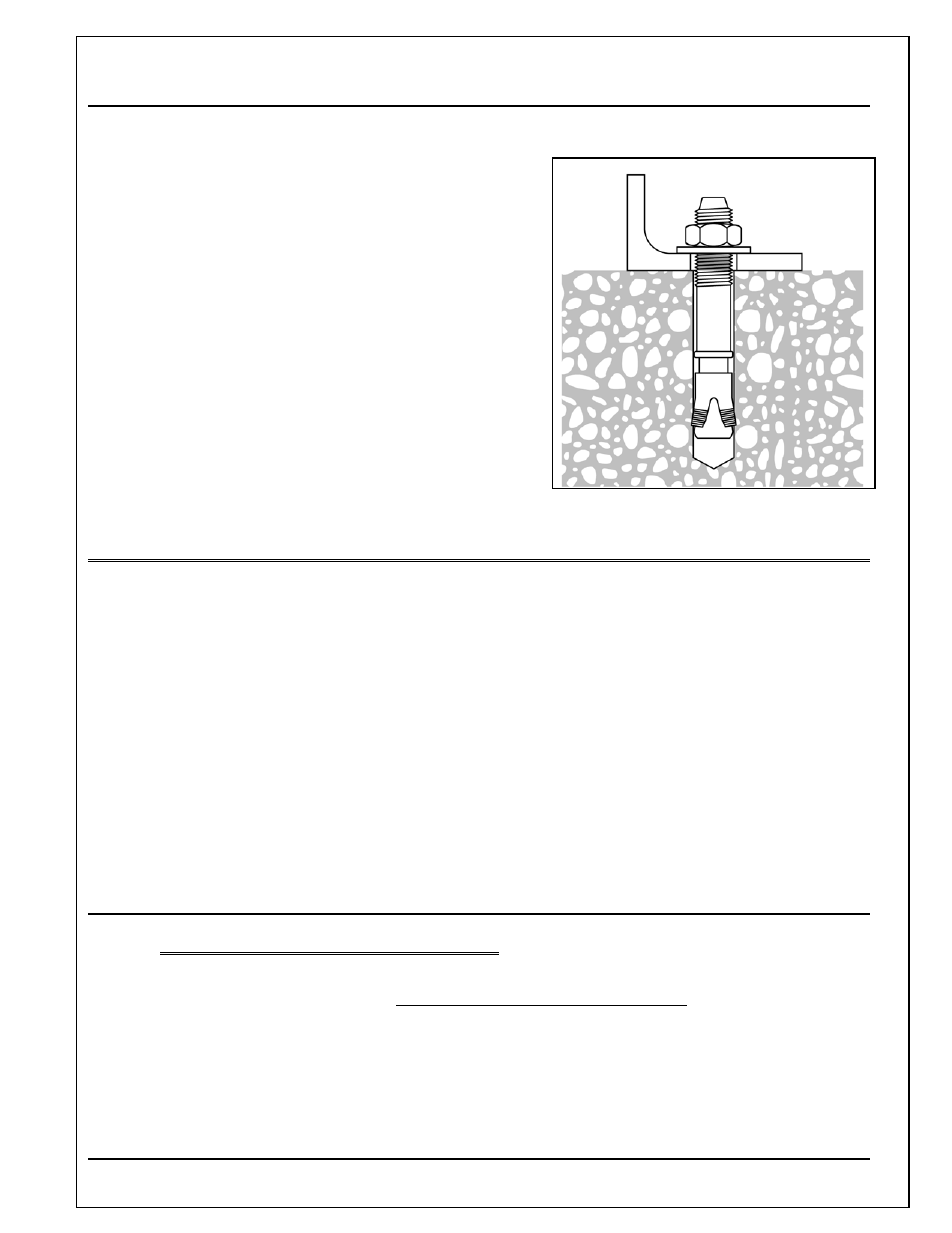

4.2 Shimming And Anchoring Lift To Concrete

Recommended concrete anchor bolts are: HILTI “Kwik-Bolt”, Molly Parabolt or similar.

1. Verify lift is positioned correctly.

2. Drill holes in concrete as specified by anchor bolt

manufacturer.

3. Install and tighten anchors as specified by anchor bolt

manufacturer.

4. After lift has been aligned, leveled and shimmed, and

anchors have been installed, pour grout under entire

base frame.

5. When grout has set and cured, tighten nuts on anchor

bolts.

6. Route hydraulic hose or electrical cord through conduit

in pit wall.

4.3 Remote Power Unit Installation

1. The remote power unit is to be located in an area protected from the elements and should be

installed prior to the lift to facilitate lift operation during installation into the pit.

2. The remote contractor power unit is equipped with power unit mounting brackets and can be wall

or floor mounted using these brackets. If equipped with a vertical power unit, optional power unit

mounting brackets must be used for wall mounting.

3. The electrical work is to be done in accordance with local codes by a qualified electrician. See the

“Maintenance” section for the standard wiring diagram.

4. If permanent electrical work is not complete, some means of temporary power with an on/off device

for the motor will be required.

5. Fill the reservoir with oil per instructions in the "Maintenance” section.

4.4 Power Unit Wiring

4.4.1 Intermittent Remote Power Unit

1. The Intermittent Power Units utilize a 1-½ or 5 HP / 208-230-460 Volt / 60 hertz / 3 phase “Super-

Torque” intermittent duty motor with (one full lift cycle per 2 minute period)

driving a high pressure

positive displacement pump assembly with an internal relief valve, check valve and down solenoid

valve.

2. Because an Autoquip "Super-Torque" motor actually delivers substantially more horsepower than

the nameplate rating, it must always be wired for heavier current-draw than standard motors of the

same nameplate rating. However, because of the "Super-Torque" motor’s starting efficiency and