Altman Lighting Track Lighting: GLOBALtrac tec 2-circuit / 2-neutral track system User Manual

Page 7

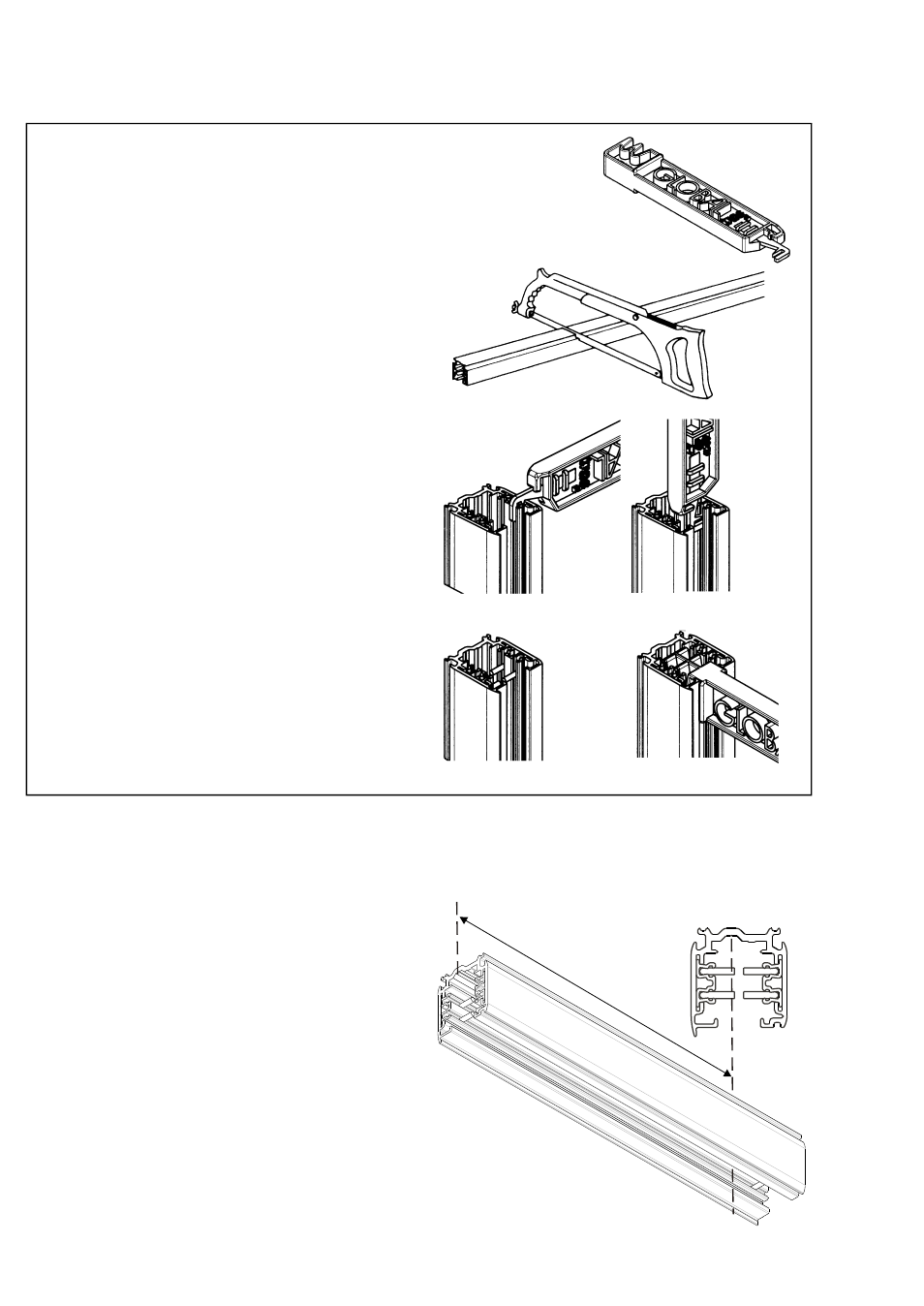

STEP 1

Carefully cut the track to length using a

hacksaw or other metal saw. Ensure that the

cut is clean and straight.

STEP 2

Insert the bending tool so that the track

conductor fits in the outermost slot at the tip

of the bending tool.

STEP 3

Rotate the bending tool 90 degrees upward.

Repeat steps 2 and 3 for all four conductors.

STEP 4

Bent conductors should look similar to the

factory finished ends, as shown.

STEP 5

Confirm correct bending by inserting the

opposite end of the tool in the end of the

track.

The standard length TEK track is supplied with the

conductor ends factory bent to allow for proper

connection of fittings. However, the track can

easily be field cut to different lengths with a

hacksaw or a circular saw intended for cutting

aluminum. After cutting, the conductor ends must

be bent in the field with the Nordic XTSV 12

bending tool.

FIELD CUTTING OF TRACK TO LENGTH

FIELD DRILLING OF MOUNTING HOLES

1

2

3

4

5

Bending tool

XTSV 12

If track is field cut, it may become necessary to drill new

mounting holes. If so, use one of the off-cut pieces with

existing mounting hole as a template for new hole to be drilled.

The drill bit should be no larger than ¼ inch in diameter. The

hole should be centered in the groove in the bottom of the

track. Remove burrs after drilling. Hole location should be in

accordance with the note below.

NOTE: A single section of the track that is 4 feet or less in

length must have one mounting opening spaced a maximum

of 6 inches from each end of the track section. Additional

openings may be provided. A single section of the track that is

greater than 4 feet in length is to be provided with mounting

openings spaced a maximum of 12 inches from each end of

the track section with additional openings provided a minimum

of every 4 feet along the length of the track section.

see N

OTE

Hole location

Max 1/4 “