5 replacing the drive belt on model dl12670, 6 lubrication for model dl12670, Important – Echo DL10570 Owners Manual v.2 User Manual

Page 21: Grease zerk

Debris Loader Owner’s Manual

17

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

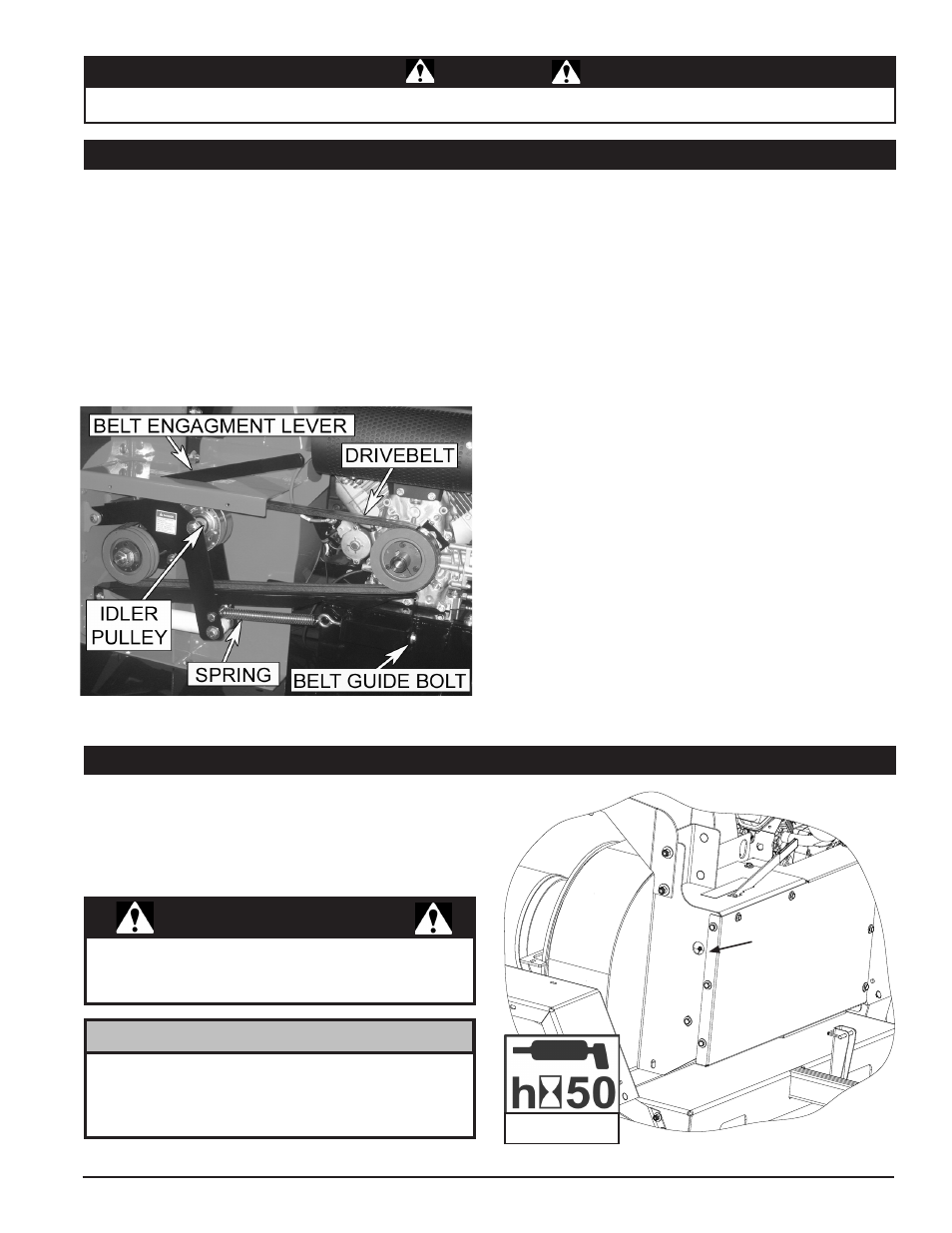

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. Replace a

cracked, frayed, worn or stretched drive belt. To replace

the drive belt, proceed as follows:

1. Move the engagement lever to the start position.

2. Shut engine off and disconnect spark plug wire.

3. Remove the belt shield by removing the 11 bolts

securing the belt shield to the rotor weldment.

4. Loosen and remove the idler pulley (Figure 5).

5.5 REPLACING THE DRIVE BELT ON MODEL DL12670

Figure 5, Drive belt, DL12670 (75124)

5. Loosen the two mounting bolts located at both ends

of the lower belt guide.

6. Loosen the four carriage bolts attaching the engine

plate to the trailer.

7. To release the tension on the belt, loosen the jam nut

and engine plate push off bolt located above the gas

tank. If needed, the gas tank can be removed for better

access to the jam nut and push off bolt.

8. Remove the old belt and install the new belt.

9. Reinstall the idler pulley.

10. Move the engagement lever to vacuum position.

11. Adjust the drive belt tension so that the belt deflection

is 7/16" when a 20 lb. load is placed against the belt

(Figure 4).

12. Tighten the four carriage bolts securing the engine

plate to the trailer.

13. Tighten the jam nut to ensure the proper deflection is

maintained.

14. Reinstall belt guide. Adjust so there is 1/8" clearance

between the belt and the belt guide.

15. Move the engagement lever to the start position.

16. Reinstall the belt shield.

17. Reconnect spark plug wire.

Figure 6, Grease zerk, DL12670

GREASE

ZERK

.18 OZ

5 GRAMS

5.6 LUBRICATION FOR MODEL DL12670

Do not over grease bearings. Overfilling can lead to

excessive heat and/or unseating of the seals. Add

grease slowly and under light pressure. Whenever

possible, rotate bearing slowly while lubricating.

NOTE

Polyurea and lithium-based greases are not

compatible. Mixing the two grease types may lead to

premature failure.

IMPORTANT

The DL12670 has one greaseable bearing located near

the engagement handle and another located at the base

of the discharge tube. Lubricate the machine periodically

with a lithium-based grease. Extreme working conditions

will require more frequent greasing.