Warning, Caution, Operation – Echo 74624S Owners Manual v.1 User Manual

Page 20

Page 14

6” Chipper Operator’s Manual

2. The controller also has a “try again” feature. The control-

ler monitors the hydraulic pressure of the feed roller. If it

senses the level is too high (the feed roller becomes ob-

structed) the controller will reverse the feed roller , remov-

ing the material trying to be chipped. The controller will

then engage the roller into the forward position and try to

feed the material again. If this cycle continues, remove

the obstruction manually. Trim or reposition material if

necessary.

4.3 STARTING THE DIESEL CHIPPER

1. Reference the Kubota Owners Manual. Before starting,

empty the cutting chamber.

2. Before starting, fill engine with oil to the correct level.

See engine manual for additional starting, operation and

maintenance instructions. Some oil usage is normal.

Check level before each use.

3. Before starting, fill fuel tank with fresh and clean diesel

fuel. For instructions on bleeding the fuel system on ini-

tial start up or if fuel runs out, see engine manual.

4. Turn key switch to preheat position (to the left). Hold in

preheat position for several seconds until glow plug indi-

cator light switches off.

5. Place throttle control in the idle position.

6. Disengaged the chipper engagement lever.

7. Push in and hold the Murphy switch push-button. Con-

tinue to hold Murphy switch in when cranking engine un-

til engine runs.

8. Activate the starter. Release the switch as soon as the

engine starts. Do not crank over for more than 10 sec-

onds. After starting the engine; hold the Murphy switch

until engine has oil pressure.

Operation

Allow the machine to come to complete stop before in-

spection or servicing.

WARNING

Handle fuel with care. Always use an approved container

and fill tank outdoors.

WARNING

Move machine to a clear, level area. Do not operate in

the vicinity of bystanders.

CAUTION

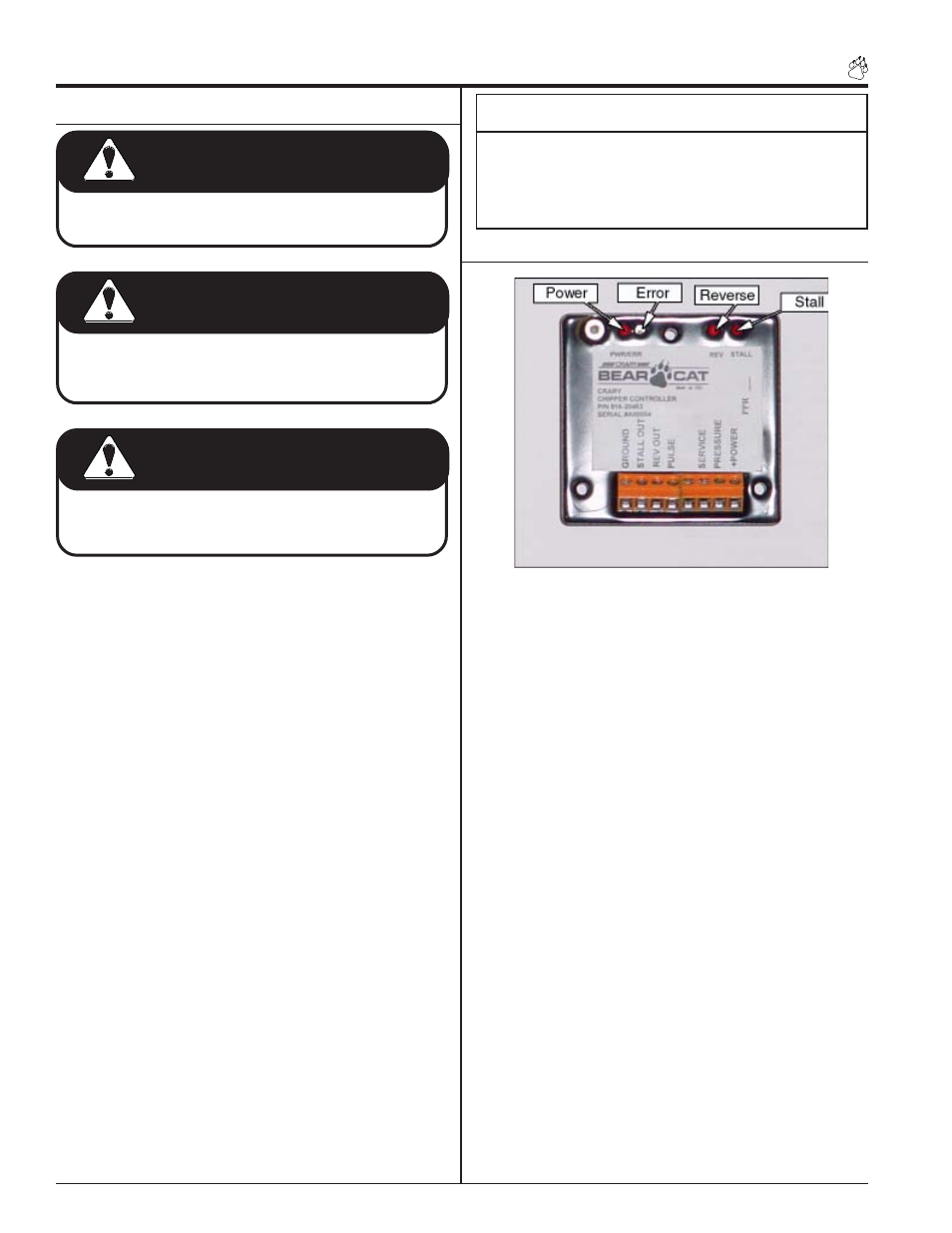

A pre-programmed hydraulic feed control equips the Bear

Cat chipper. The controller serves a variety of functions

including monitoring chipper rotor RPM, controlling the feed

roller, and providing routine maintenance alerts. The controller

has an on/off feature located below the control panel. If the

controller becomes damaged, the chipper will still run with

the controller shut off, however all of the controller functions

will be disabled. The control arm will control the feed roller.

The controller is positioned under the control panel.

The controller functions are further detailed below:

1. The controller operates the feed roller. The controller moni-

tors the RPMs of the chipper rotor and if it drops below

the preset range the feed roller stops. When the RPMs

reach an acceptable level, the feed roller will reengage.

4.4 HYD FEED CONTROL

Fig. #18 Controller

NOTE

The Murphy switch system will shut the engine off if

the oil pressure is too low or if the engine temperature

is too high. If the engine will not run or shuts off for

these reasons, consult your local dealer.