Echo 76624 Owners Manual v.1 User Manual

Page 18

16

6 INCH CHIPPER

OPERATION

4.7 smarT relaY

the bear Cat chipper is equipped with a Smart Relay

hydraulic feed control that is located beneath the control

panel. It monitors the chipper rotor RPM and helps to

regulate the feed roller.

When chipper rPm drops below the preset range the

feed roller is stopped automatically to help the chipper

process backed up materials. the screen will read

"Forward Feed Stopped."

When the rPms are back up to an acceptable level the

feed roller will automatically reengage. the screen will

read "Forward Feed available."

for s & f models only, if the safety bar has been ac-

tivated, the feed roller will stop automatically and the

screen will read "Forward Feed Stopped." Push the

reset/override button to resume forward feed.

When the hydraulic pressure is too high, (if the feed

roller becomes obstructed) the controller will reverse the

feed roller momentarily to try to remove the material that

wasn't chipped. the screen will read "try again feature

activated." the controller will then engage the roller into

the forward position and try to feed the material again.

if this cycle continues, the obstruction will have to be

removed manually, or material to be chipped should

be removed, trimmed, and/or repositioned.

Your smart relay comes preprogrammed at the fac-

tory. If it should malfunction and the screen reads "No

Program available," contact your dealer immediately.

the Smart Relay will not allow the chipper to operate

until it has been properly programmed.

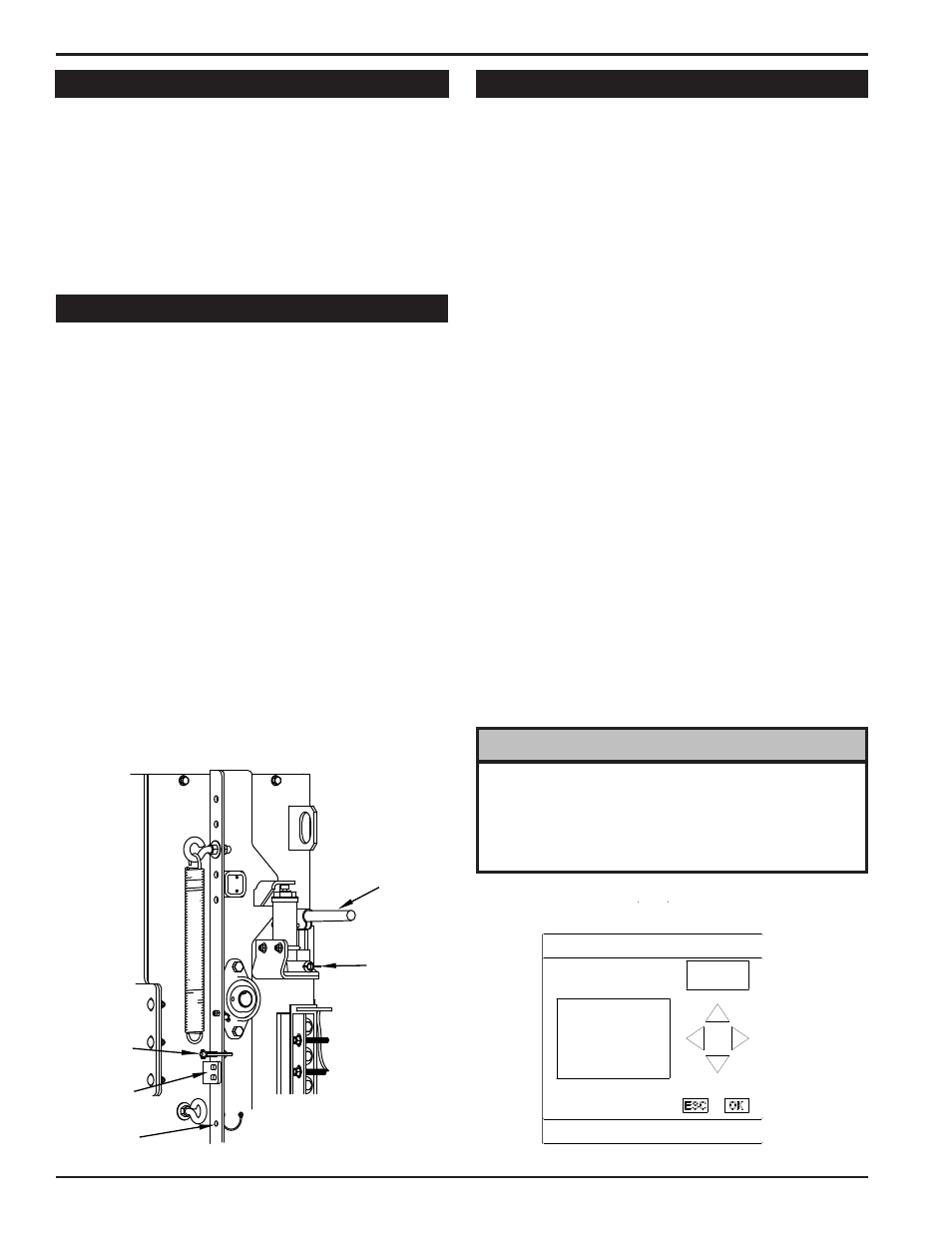

4.6 removing Jammed maTerials

The feed roller lift jack is used to raise the feed roller if

chipping material becomes wedged in or behind the feed

roller. Raise the feed roller to safely remove the material.

To release Jammed maTerials:

turn the machine off and allow all moving parts to come

to a complete stop.

Remove the retaining pin from storage position (see

figure below).

Turn check valve clockwise to engage the jack pump.

Once the jack is engaged, pump the handle to raise

the feed roller until the lock pin position aligns with one

of the support bracket holes.

Secure the position by putting the lock pin through the

support bracket and lock pin position.

Clear materials out from underneath the feed roller.

Remove the lock pin.

turn the check valve counterclockwise to disengage

the pump and lower the jack.

Replace retaining pin in storage position.

1.

2.

3.

4.

5.

6.

7.

8.

9.

idec SmartRelay

Feed Roller

Jack

Retaining

Pin in

Storage

Position

Support

Bracket

Lock Pin

Position

Check

Valve

Select limbs that are up to 6 inches in diameter.

trim side branches that cannot be bent enough to

feed into the chipper chute.

Small diameter branches can be held together in a

bundle and fed in simultaneously.

the actual feed rate of the limb into the chipper will

depend on the type of material fed, and sharpness of

the cutting blades.

●

●

●

●

4.5 limb selecTion and feeding

noTe

The RPM sensor on the rotor must be flashing or the

controller won’t work. Clearance between the sensor

and the bolt must be between 1/32” and 3/32”. there

are also two sensors in the feed roller control box. these

sensors must have a clearance of 5/64" (2mm).