Danger, Blade measure here anvil – Echo CH123DH Owners Manual v.2 User Manual

Page 20

12 INCH CHIPPER

16

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE, REMOVE KEY,

DISCONNECT THE BATTERY CABLES AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

With the chipper motor running and the engagement

1.

handle DISENGAGED, raise and secure the feed

roller (Section 4.6).

If the anvil edge is damaged or worn unevenly, remove

anvil and use one of the other three edges. If all edges

are damaged or worn unevenly, replace the anvil.

NOTE

5.6 SETTING BLADE CLEARANCE

Ensure that the feed roller is raised and secure before

entering the feed chute. Failure to do so can result in

serious injury or death.

DANGER

Shut the engine off, remove the key, and allow the rotor

2.

to come to a complete stop.

Lift the knife access cover and secure with the lockup

3.

pin (Sec. 4.8).

Rotate the disk until a chipping blade is even with the

4.

anvil.

Secure the chipper disk to prevent movement during

5.

adjustment (for example, by wedging a piece of wood

between a rotor paddle and the housing).

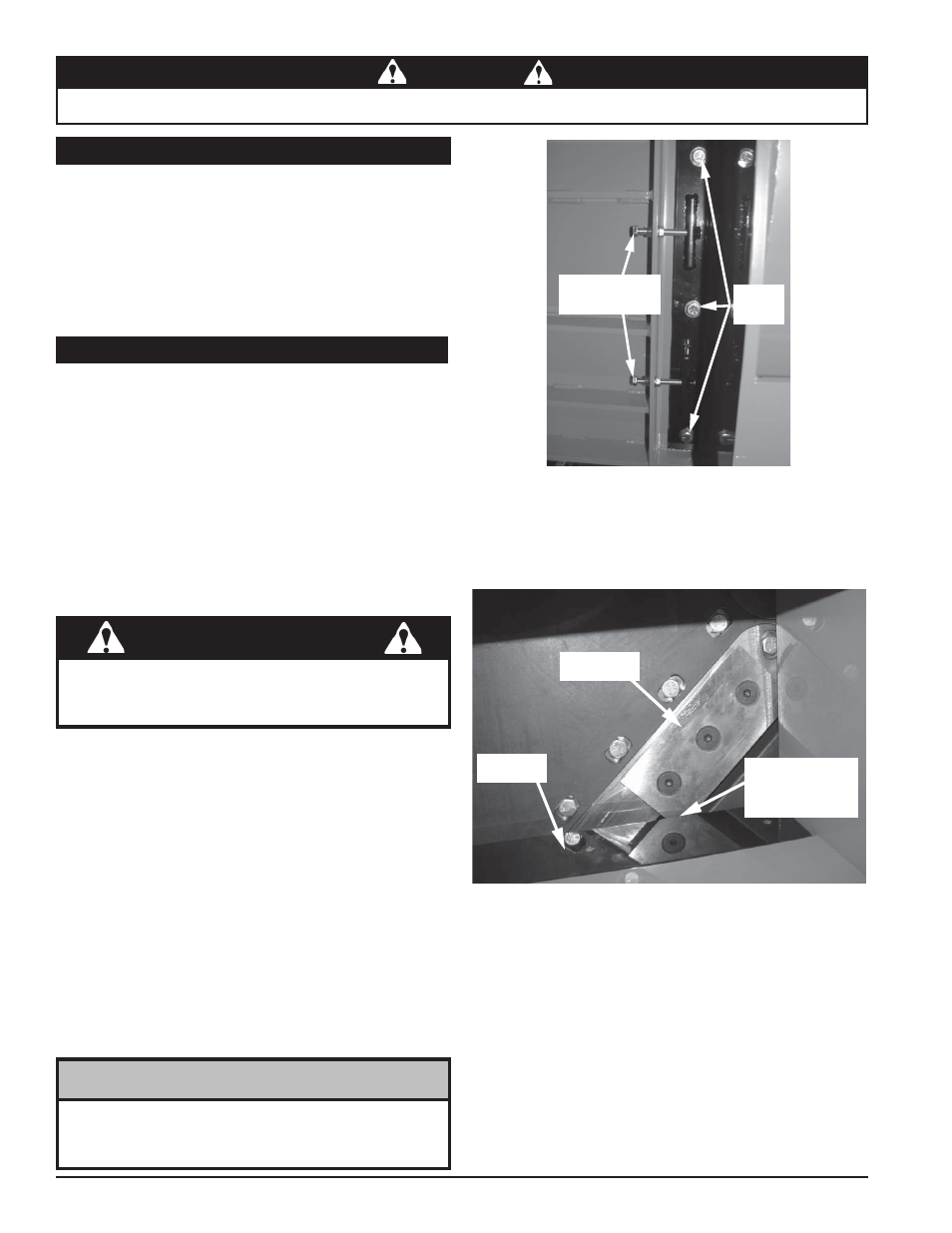

Loosen the three 1/2" x 1-1/2" bolts that secure the

6.

anvil to the chipper housing (access is from underneath

machine, see picture).

Loosen the two 3/8" adjustment nuts located inside the

7.

anvil backplate (access is from underneath machine,

see picture).

Adjustment

Nuts

Anvil

Bolts

View of anvil bolts and adjustment nuts from underneath machine

Blade

Measure

Here

Anvil

Measuring clearance between blade and anvil

Secure the disk to prevent movement during installation.

1.

Place a blade on the disk and attach with three 5/8"

2.

x 3" bolts and nuts. Torque to 230 ft-lbs. Repeat for

remaining blades.

Lower the knife access cover.

3.

Secure the knife access cover to the chipper housing

4.

using two 1/2" x 1-1/4" bolts, nuts and washers.

5.5 INSTALLING THE BLADES

Check the clearance every 8 hours of operation and adjust

if needed. The chipping anvil is reversible. All four sides

of the anvil can be used for chipping. Use the following

guide when setting the blade clearance:

If you are chipping materials that are primarily

•

smaller

than 6 inches, use an anvil gap of 1/4” to 3/8”.

If the materials are

•

6 inches and larger, use an

anvil gap of 3/8” to 7/16”.

To adjust the anvil:

Measure the clearance between the chipping blade

8.

and the anvil from inside the feed chute. Adjust both

nuts equally until the clearance between the chipping

blades and the anvil is correct.

Rotate the disk to ensure there is proper clearance be-

9.

tween ALL four chipping blades and the anvil. The anvil

gap may be different for each blade. Ensure the gap is

set for the closest blade. Adjust anvil if necessary.

Once proper clearance is achieved, tighten the three

10.

1/2" x 1-1/2" bolts to secure the anvil to the frame.

Tighten the two 3/8" adjustment nuts located inside the

11.

anvil backplate.

Lower the knife access cover by removing the lock pin,

12.

and turning the wing nut on the jack to the left.

Remove the feed roller lock up pin, lower the feed roller

13.

and resume operation.