English – Echo CH123DH Owners Manual v.2 User Manual

Page 17

12 INCH CHIPPER

13

ENGLISH

OPERATION

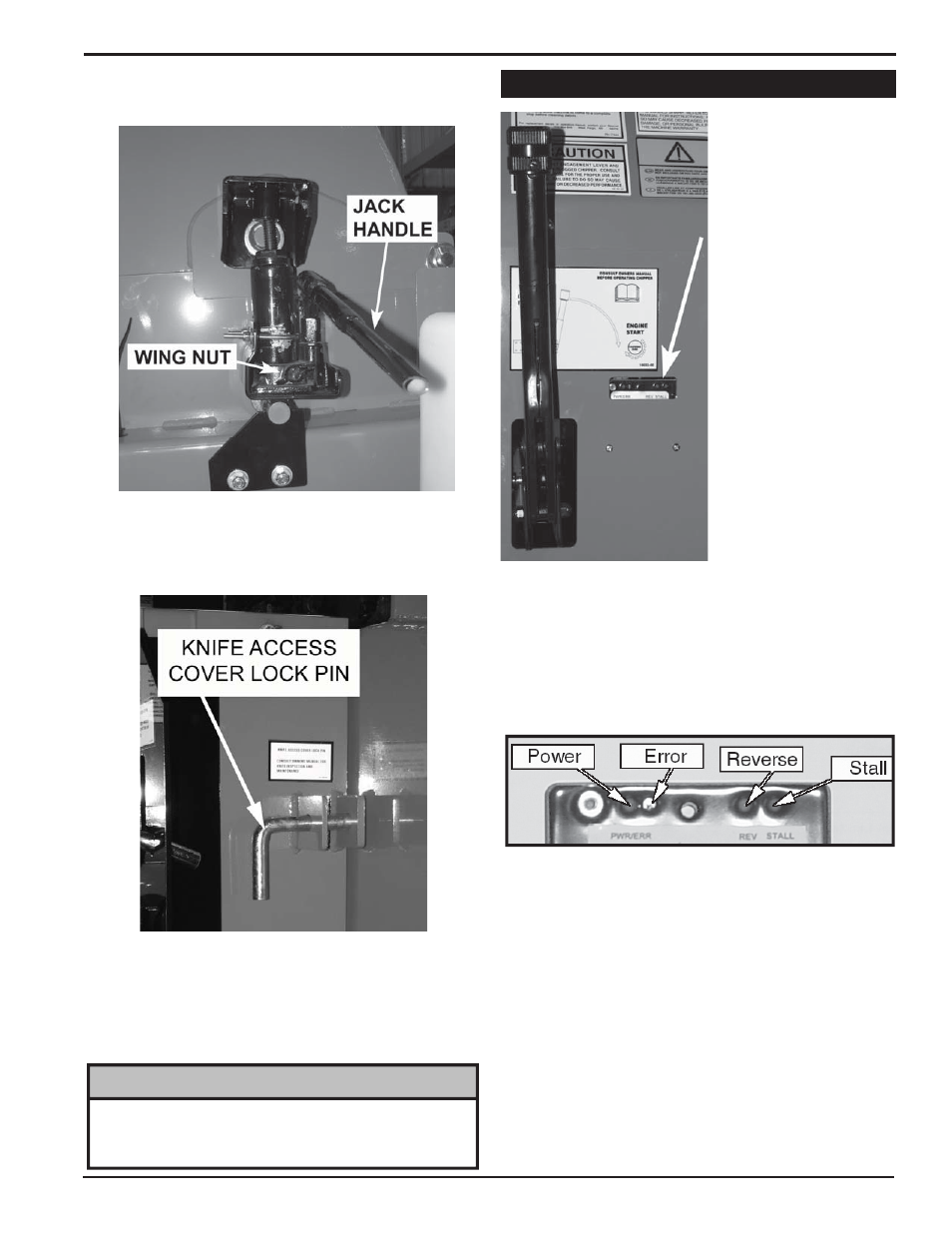

Lift the engine hood and locate the knife access cover

3.

jack inside the chipper housing next to the hydraulic

fluid reservoir (see below).

Turn the wing nut located on the bottom of the jack to

4.

the right and pump the handle.

Secure the cover using the lock pin located on the

5.

outside of the chipper housing (see below).

To lower the cover, remove the lock pin and turn the

6.

wing nut located on the jack to the left to release the

hydraulic pressure.

Secure the knife access cover to the chipper housing

7.

using two 1/2" x 1-14" bolts, nuts and washers.

When closing the rotor cover, make sure the bolts are

securely tightened. If they are not, the safety switch

may respond as though the battery is dead.

NOTE

The chipper is equipped

with a pre-programmed

feed controller located

next to the engagement

handle. The controller

monitors chipper rotor

RPM, controls the feed

r o l l e r, a n d p r o v i d e s

routine maintenance

alerts.

The controller functions

are further detailed

below:

The controller

1.

monitors the RPM of the

chipper rotor. If the RPM

drops below the preset

range, the feed roller

is stopped. When the

RPM reach an accept-

able level, the feed roller

is reengaged.

The controller

2.

also has a “try again”

feature. If the hydraulic pressure of the feed roller is

too high (if the feed roller becomes obstructed) the

controller will reverse the feed roller, removing the

unchipped material. The controller will then reengage

the roller forward and try to feed the material again. If

this cycle continues, remove the obstruction manually.

Trim or reposition material if necessary.

Lights on the controller give the following information:

3.

Error light will flash 10 times every 100 hours

•

of operation upon startup to indicate the engine

oil should be changed.

Error light will flash 5 times every 15 hours of

•

operation upon startup to indicate the chipper

blades should be sharpened.

Steady power light indicates controller operat-

•

ing normally, blinking power light indicates low

or no power to the controller.

To reset service alerts, locate the light green wire in

4.

the engine compartment next to the hour meter. Con-

nect the green wire to the red wire connector for five

seconds.

4.9 FEED CONTROLLER