10 replacing the drive belt – Echo CH611DH Owners Manual v.6 User Manual

Page 28

24

6 INCH CHIPPER

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

DISENGAGE THE HYDRAULICS, AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

5.10 REPLACING THE DRIVE BELT

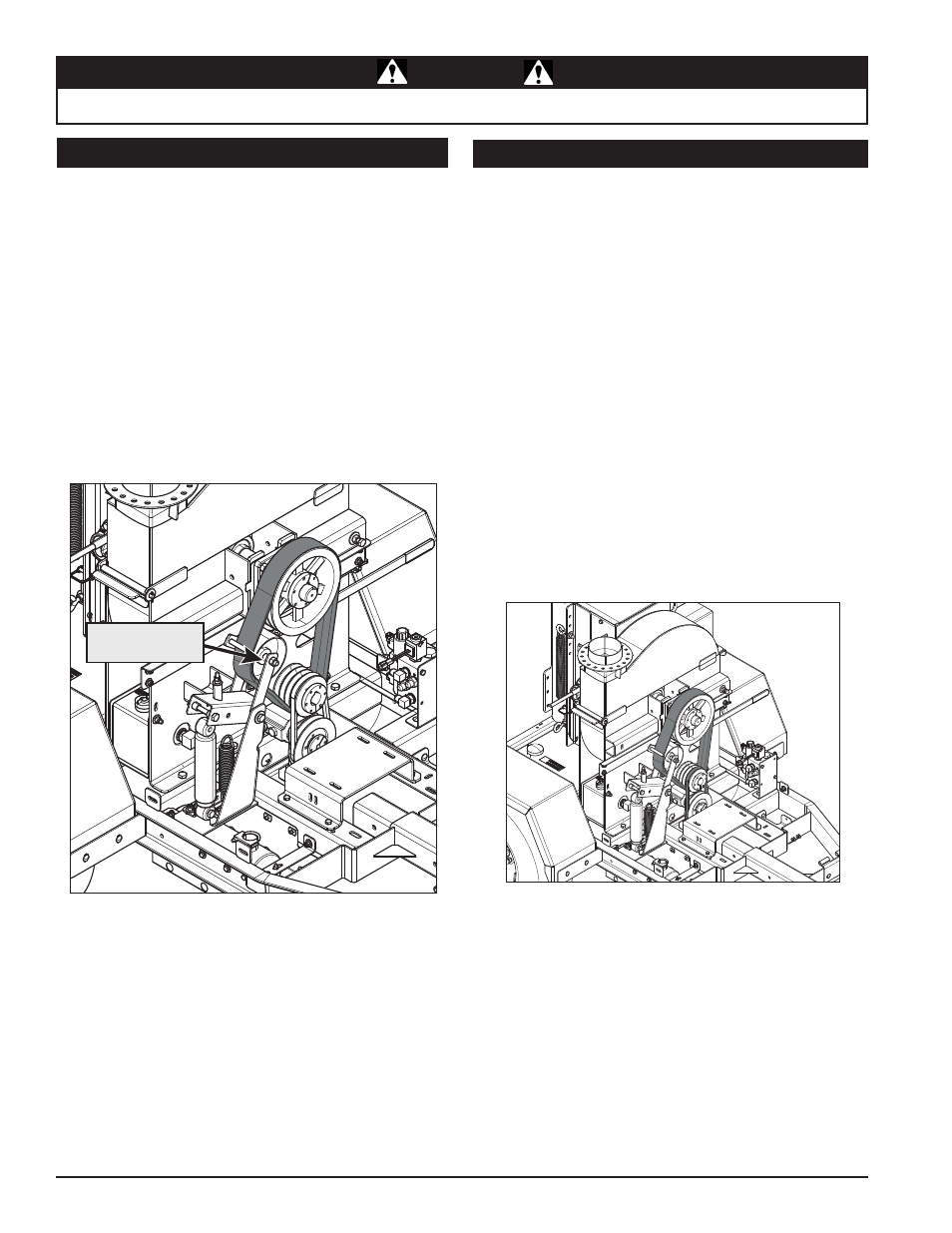

Figure 5.8, Unscrew the bolt to remove the idler pulley

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. If the belt is

cracked, worn, frayed, or stretched, replace it. Replace

belt with original banded belt type only. Do not use single

type belts.

To replace the belt:

1. Lift up the engine hood.

2. Remove idler pulley by loosening the 1/2” mounting

hardware.

3. Lift belt idler pulley off the idler arm weldment.

4. Remove the drive belt from the pulleys and discard.

5. Inspect pulleys for wear. Replace the pulleys if they

are cracked or worn so that the belt contact area is not

smooth and flat.

IDLER PULLEY

HARDWARE

5.11 REPLACING HYDRAULIC DRIVE BELT

1. Remove drive belt according to instructions in Section

5.10.

2. Loosen the two bolts under the pump. Access is from

underneath chipper (see figure).

3. Slide the pump up, remove the loosened hydraulic belt

and discard.

4. Install the new hydraulic belt.

5. Replace the drive belt according to directions in Section

5.10

.

6. Tighten the nuts on the adjusting bolt to move the

pump mounting bracket.

Check belt tension and adjust

if needed. The belt deflection at the center of the belt

should be 7/16" with a 20 lb. load.

7. Tighten the mounting bolts on the pump mounting

bracket to the proper torque.

The condition of the hydraulic drive belt should be checked

annually, or after every 25 hours of operation. Replace the

belt if it is cracked, worn, frayed, or stretched.

To replace the belt:

Figure 5.10,

Guide for routing belts

6. Install new belt on pulleys and lower belt idler.

7. Reinstall the belt idler pulley into the idler arm weldment

using the 1/2” hardware. Tighten bolt to proper

torque.

8. Check pulley alignment by placing a straight edge across

the face of both pulleys. Adjust the lower (engine) pulley

if necessary to bring them into alignment.

9. Check belt tension and adjust if needed. The belt

deflection at the center of the belt should be 7/16" with

a 20 lb. load. If necessary, adjust spring tension.

10. Shut engine hood.