9 replacing drive belt, 10 change oil, 9 replacing drive belt 5.10 change oil – Echo CH911DH Owners Manual v.7 User Manual

Page 21: Caution, English

9 INCH CHIPPER

17

ENGLISH

SERVICE & MAINTENANCE

Before inspecting or servicing any part of this machine, shut off power source,

and make sure all moving parts have come to a complete stop.

WARNING

cauTion

Failure to maintain proper fastening torque on bolts

may result in damage to the chipper and/or personal

injury!

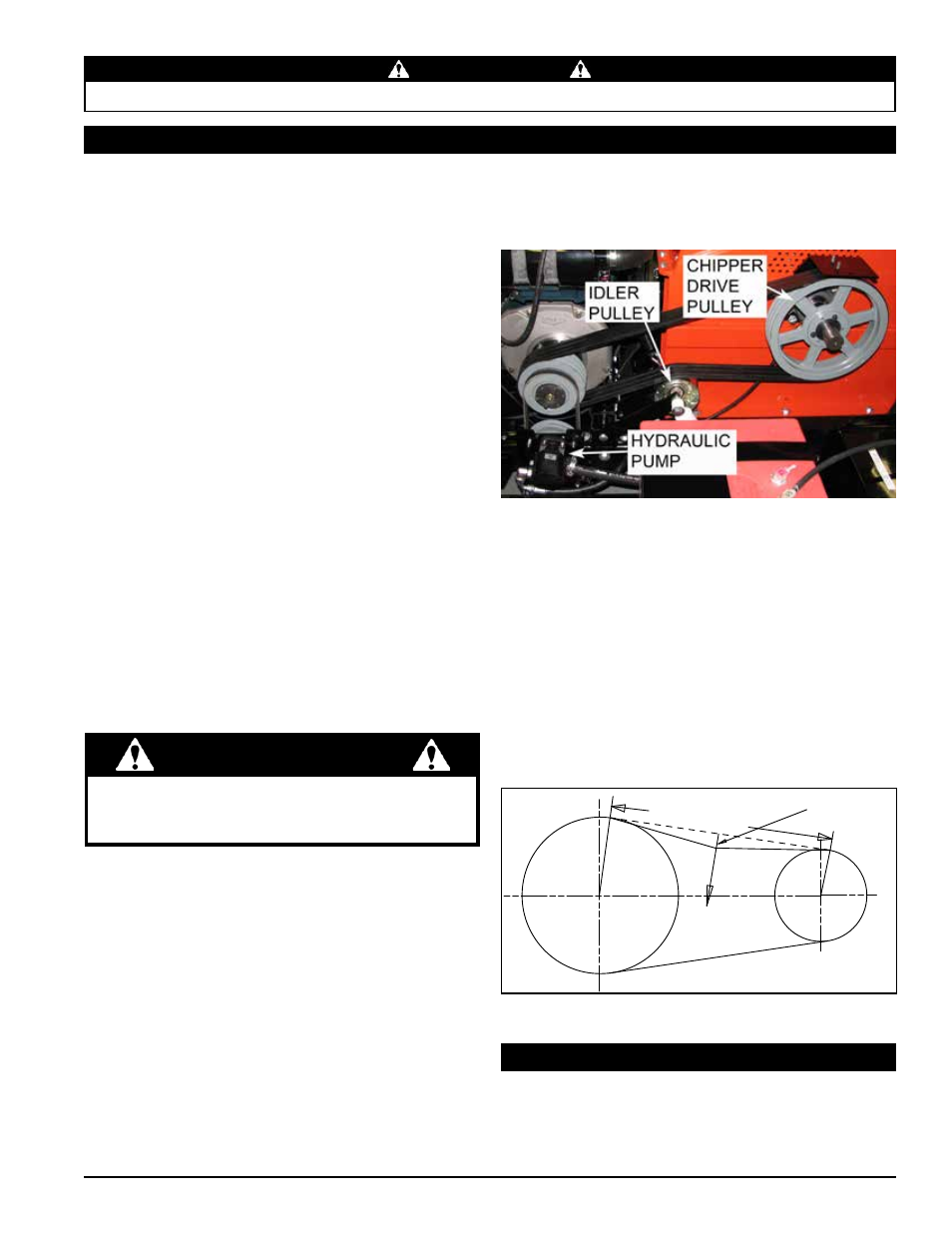

5.9 replacinG Drive BelT

Figure 5.4, Drive belt

Figure 5.5, Belt Tension

5.10 chanGe oil

Check the oil level before each use. Change oil as directed

in the engine owner's manual.

SPAN LENGTH

FORCE

20 LBS

7/16" DEFLECTION

Check the condition of the drive belt annually or after every

25 hours of operation, whichever comes first. If the belt is

cracked, worn, frayed, or stretched, replace it. Replace

belt with original banded belt type only. Do not use single

type belts.

To replace the belt:

1. Shut off engine.

2. Remove drive belt shield.

3. Remove the hydraulic pump belt by loosening the bolts

on the hydraulic pump (Figure 5.4).

4. Take the tension off the drive belt by depressing the belt

engagement pedal. Remove the drive belt from pulleys.

9. Slide belt side collar on shaft against belt side bearing.

Make sure the collar set screw lines up with the sensor.

Slide bushing onto shaft with flange against collar and

lock bushing to shaft. Attach large pulley to bushing by

inserting the bolts back into the non-threaded holes.

Tighten equally until snug. Torque bolts to 180 inch-

lbs.

10. Replace drive belts on pulleys.

11. Check pulley alignment with a straight edge and adjust

engine if needed. Check belt tension. Belt deflection

at the center of the belt should be 7/16" when a 20

lb. load is placed against the belt. See Adjusting Belt

Tension

12. Replace hydraulic pump belt. Readjust hydraulic

pump belt tension by sliding the hydraulic pump in the

mounting slots. Tighten bolts. (Skip to step 13 if the VIN

number is 5VJAA00178W001015 and above.)

13. Check to make sure you knife to anvil gap is a 1/16”

to your closest blade and torque the anvil bolts to 75

ft-lbs..

14. Replace belt guides and belt guard and resume

operation.

15. Depress belt engagement pedal, start engine, engage

drive belt, and test unit. Readjust pulleys and belt

tension if needed.

5. Install the new drive belt on pulleys.

6. Check pulley alignment with a straight edge and adjust

engine if needed.

7. Check belt tension and adjust if needed. The belt

defelction at the center of the belt should be 7/16" when

a 20 lb. load is placed against the belt. See Figure 5.5.

8. Reinstall hydraulic pump belt. Readjust hydraulic

pump belt tension by sliding the hydraulic pump in the

mounting slots. Tighten bolts.

9. Replace belt guard.

10. Depress belt engagement pedal, start engine, engage

drive belt, and test unit. Readjust pulleys and belt

tension if needed.