5 sharpening the blades, 6 setting blade clearance, English – Echo CH911DH Owners Manual v.7 User Manual

Page 19

9 INCH CHIPPER

15

ENGLISH

SERVICE & MAINTENANCE

Before inspecting or servicing any part of this machine, shut off power source,

and make sure all moving parts have come to a complete stop.

WARNING

5.6 seTTinG BlaDe clearance

1. Stop engine and wait for all moving parts to stop.

2. lift rotor access cover and expose rotor.

3. Remove the lock pin from storage position (see Figure

5.3)

4. Turn check valve clockwise to engage the jack.

5. Pump the handle to raise the feed roller until the lock pin

position aligns with one of the support bracket holes.

6. Secure the position by putting the lock pin through the

support bracket and lock pin position.

7. Accessing the anvil from under the feed roller, loosen the

three 1/2" bolts that hold the chipper anvil to the frame.

8. Clean the anvil surface area thoroughly. If the chipping

anvil edge is damaged or worn unevenly, remove the anvil

and use one of the other three edges.

9. Adjust anvil inward or outward. Check to ensure a

clearance of 1/16" to 1/8" with all blades. Apply lock

tite and torque bolts to 75 ft. lbs.

10. Remove lock pin and put it back into its storage position.

Turn the check valve counterclockwise to disengage

and lower the jack.

11. Close rotor access cover and secure with bolts.

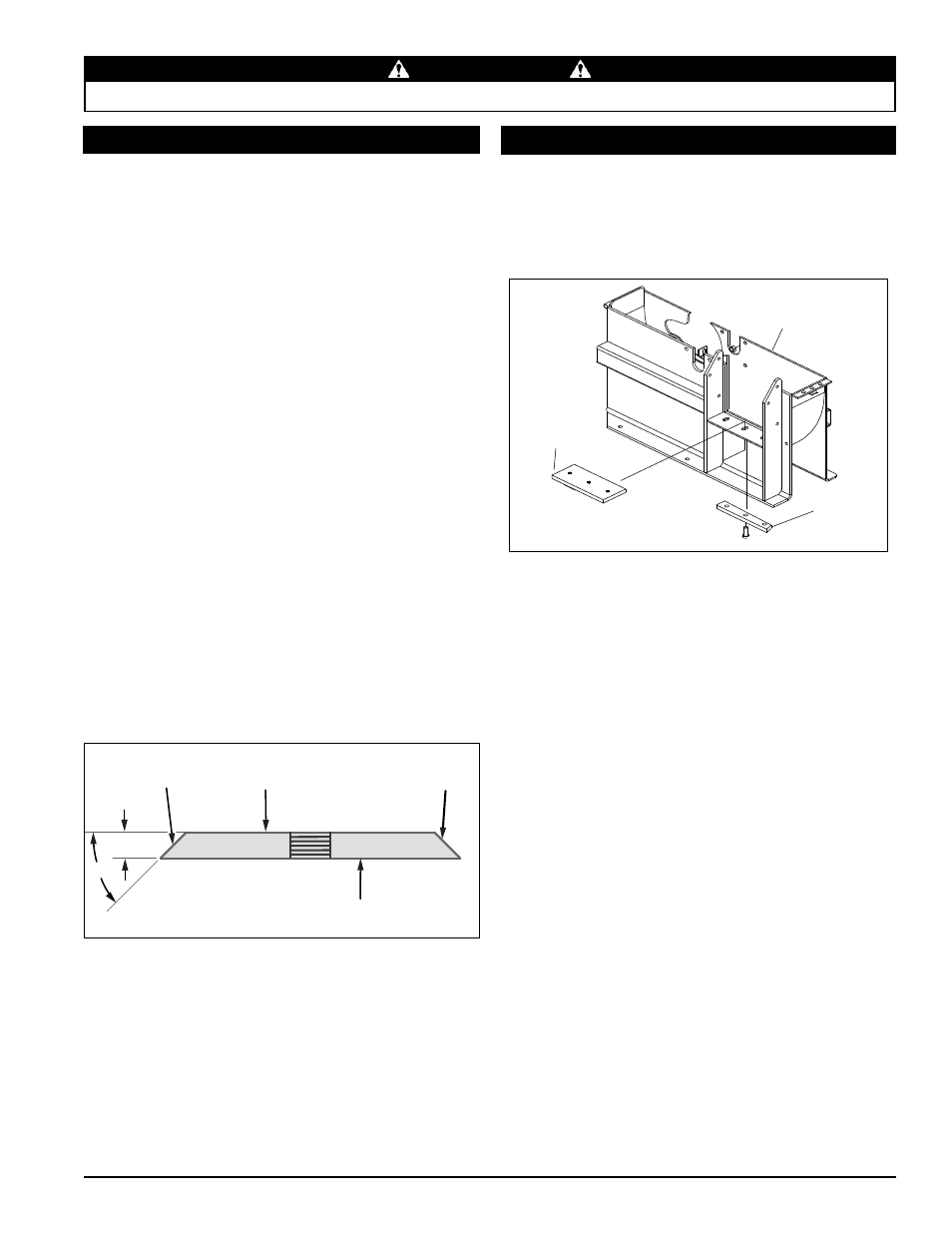

CHIPPER

ANVIL

SPACER

ROTOR

HOUSING

Figure 5.2, Chipping anvil location

Figure 5.1, Sharpening the chipper blades

45˚

SHARPENED

SURFACE

MOUNTING SURFACE

(DO NOT GRIND)

.50”

SHARPENED

SURFACE

MOUNTING SURFACE

(DO NOT GRIND)

5.5 sharpeninG The BlaDes

The blades can be ground on a bench grinder or by a

professional.

1. Never sharpen or grind the mounting surfaces of the

blades. This will cause the edge to roll and the blade will

be damaged, resulting in poor chipping performance.

2. Regrind the angled edge of the chipping blades to 45

degrees (Figure 5.2). Make sure some type of fixture is

used to correctly hold the blade at the proper angle.

3. Be careful when grinding so that the blade does not

become overheated and change color. This will remove

the heat-treated properties.

4. use short grinding times and cool with water or some

type of liquid coolant.

5. Remove an equal amount off each blade to maintain

rotor balance.

6. Small imperfections such as nicks and burrs on the flat

side of the blade will not affect the chipping performance

of the machine.

7. For blades that have been repeatedly sharpened,

ensure that the sharpened surface extends past the

chipping slot opening. If it does not extend past the

opening, the blades should be replaced.

The chipping blades should clear the anvil by 1/16" to 1/8".

Check the clearance every 8 hours of operation and adjust

if needed. The chipping anvil is reversible. All four sides of

the anvil can be used for chipping.

To adjust the anvil: