Important – JLG 80HX_HX+6_HXER ANSI Service Manual User Manual

Page 90

SECTION 4 - BOOM & PLATFORM

4-10

– JLG Lift –

3120271

4.3

WEAR PADS

1.

Shim up wear pads within 1/16 in. (1.59 mm) toler-

ance between wear pad and adjacent surface.

2.

Replace wear pads when worn within 1/8 in. (3.18

mm) of threaded insert.

4.4

TELESCOPE CYLINDER ECCENTRIC

BUSHING

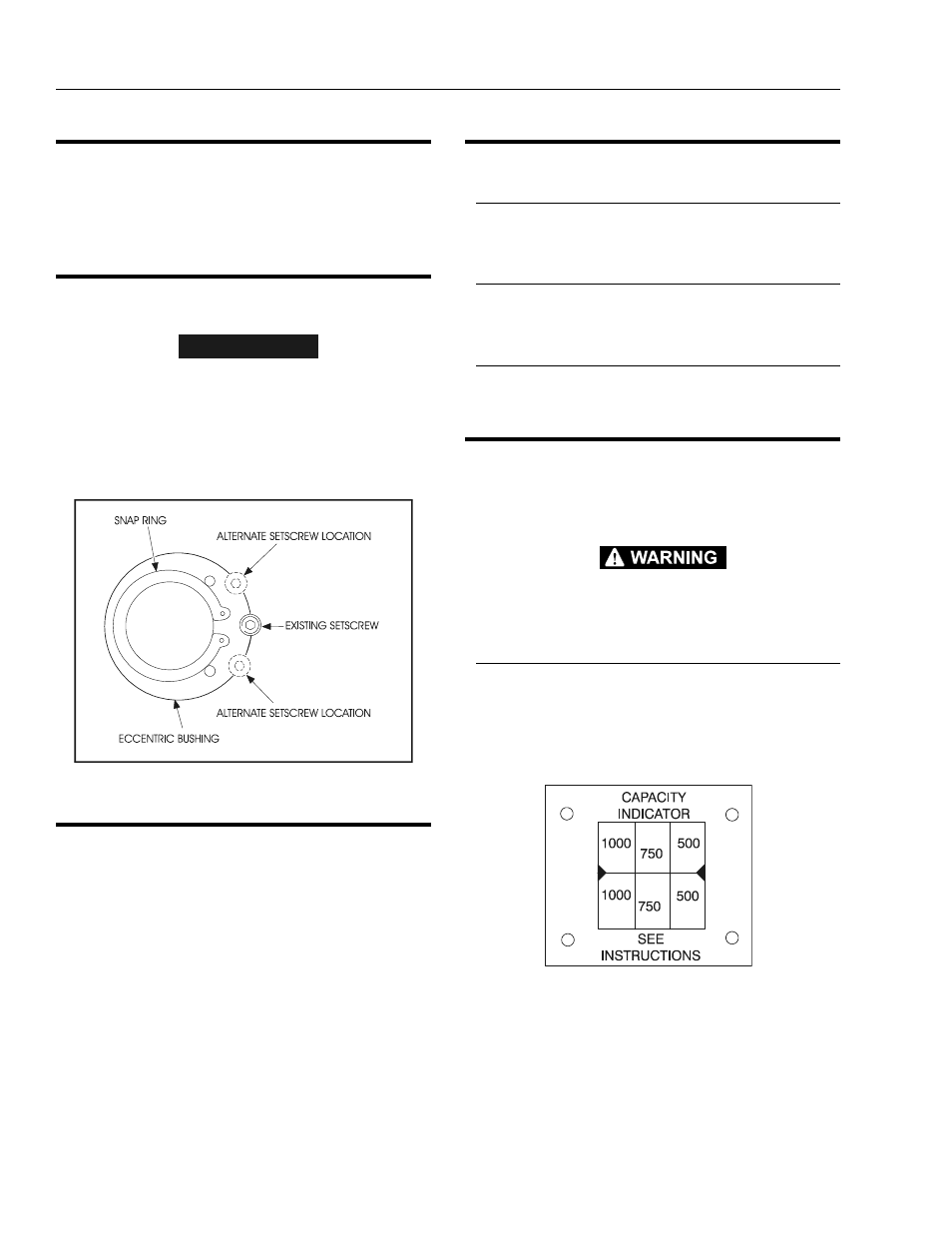

IMPORTANT

RELOCATE ALTERNATE SETSCREW HOLE ONLY WHEN REPLAC-

ING ECCENTRIC BUSHING.

When replacing the eccentric bushings, drill 5/16" dia. x 3/

4" deep, tap 3/8-16NC x 9/16" deep for a new setscrew

(bushing to boom) either above or below original holes.

Allow enough room between the holes for strength while

staying on the thick side of the bushing. (See Figure 4-4.)

4.5

HORIZONTAL HIGH SPEED CUTOUT

SWITCH ADJUSTMENT PROCEDURE

Adjust the switch to trip when the boom reaches 0

degrees +0 degrees /-3 degrees.

4.6

CONTROLLERS

PQ

Refer to separate publication (3120351) for complete trou-

bleshooting, wiring and replacement parts.

OEM

Refer to separate publication (3120344) for description

troubleshooting, wiring and replacement parts.

VICKERS (All Hydraulic)

Refer to separate publication (3120335) for complete trou-

bleshooting, wiring and replacement parts.

4.7

CAPACITY INDICATOR

The capacity indicator is a mechanical gage that indicates

the allowable maximum weight in the platform in reference

to the angle of the boom.

THE CABLE ADJUSTMENT AND DECAL REPLACEMENT ARE

CRITICAL TO INSURE AN ACCURATE READING OF THE CAPAC-

ITY INDICATOR.

Capacity Indicator Cable Adjustment

1.

Position main boom top plate and platform to be

parallel to the floor.

2.

Adjust the cable to locate the dial in the capacity

indicator box so that the indicator line and calibra-

tion arrows on the nameplate are aligned.

Figure 4-4. Telescope Cylinder Eccentric Bushing