JLG 80HX_HX+6_HXER ANSI Service Manual User Manual

Page 47

SECTION 3 - CHASSIS & TURNTABLE

3120271

– JLG Lift –

3-9

Cleaning and Inspection

1.

Clean all parts thoroughly.

2.

Closely inspect all parts for excessive wear, cracks,

and chips. Replace parts as necessary.

3.

Discard seals and o-rings.

4.

Closely inspect bearings and bearing contact sur-

faces. Replace as necessary.

NOTE: Bearings may be reused if, after thorough inspec-

tion, they are found to be in good condition.

Assembly

NOTE: Lubricate all seals, o-rings, cylinder of power plate

and piston with clean hydraulic oil prior to assembly.

1.

Use the reverse of the disassembly procedure with

the following notes and additions.

2.

Worn o-rings and damaged or worn teflon back-up

rings must be replaced prior to assembly.

3.

If replacement of bleeder (19) is necessary, install 1/

2 to 3/4 turns beyond finger tight.

4.

Assemble piston (14) into power plate (20) using a

shop press, being careful not to damage the o-rings

or teflon back-up rings. Visually align the center of

the cutouts in the piston with the torque pin (9) holes

in the power plate.

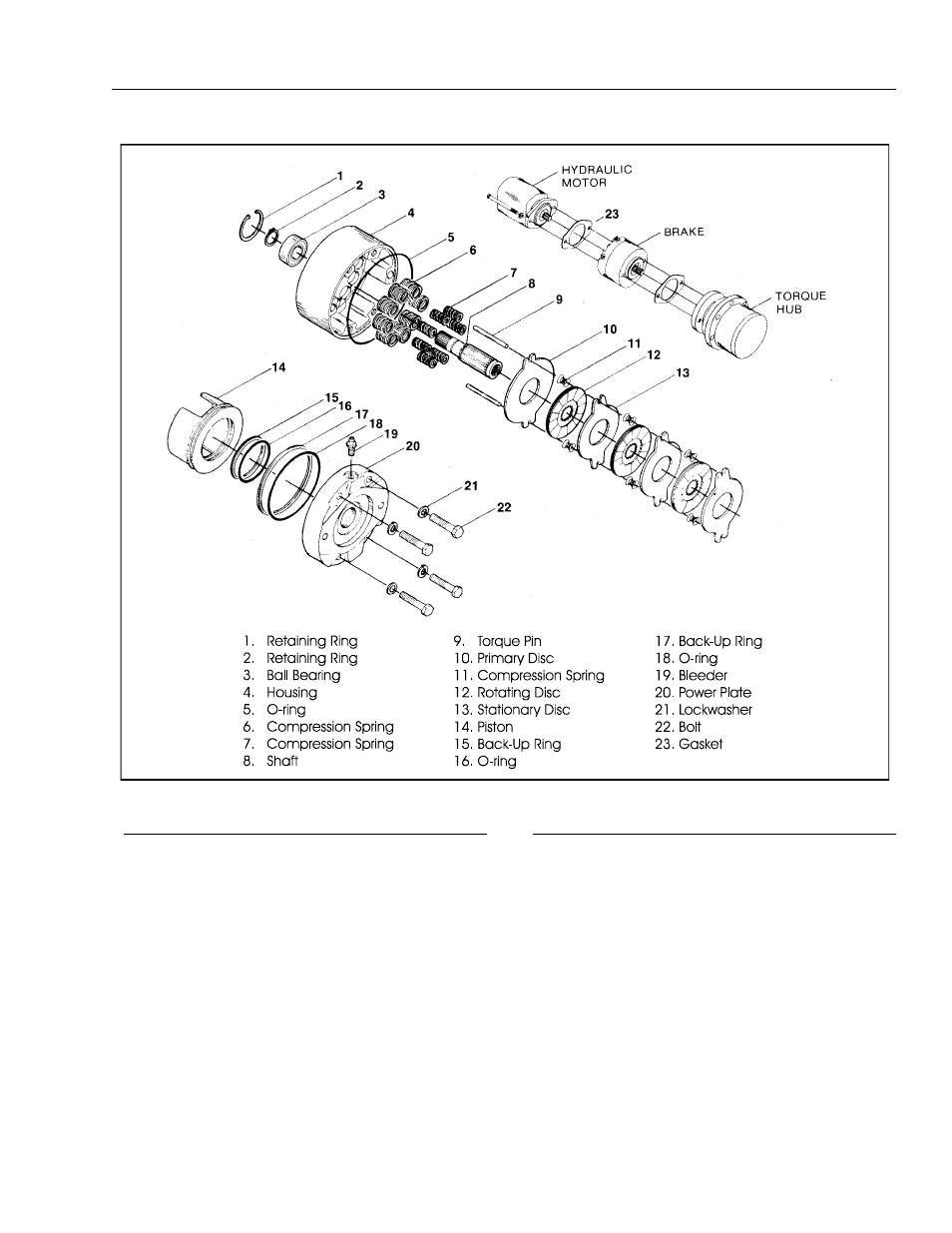

Figure 3-2. Drive Brake, Ausco - Machines Built Prior to October 1987