Assembly, 10 footswitch adjustment, 11 boom limit switches – JLG M400 Service Manual Service Manual User Manual

Page 126: Assembly -10, Footswitch adjustment -10, Boom limit switches -10, Platform support torque values -10

SECTION 4 - BOOM & PLATFORM

4-10

– JLG Lift –

3121827

Assembly

NOTE: For location of components See Section 4-7., Loca-

tion of Components - Articulating Jib Boom.

1. Align lift cylinder, rotator support top tube holes, and

top tubes. Using a soft head mallet, install cylinder

pin #6 into articulating jib boom and secure with

mounting hardware.

2. Align bottom tubes with attach holes in rotator sup-

port. Using a soft head mallet, install rotator support

pin #5 into articulating jib boom and secure with

mounting hardware.

3. Align articulating jib boom with attach hole in articu-

lating jib boom pivot weldment. Using a soft head

mallet, install rotator support pin #4 into articulating

jib boom and secure with mounting hardware.

4. Align bottom tubes with attach holes in articulating

jib boom pivot weldment. Using a soft head mallet,

install rotator support pin #3 into articulating jib

boom pivot weldment and secure with mounting

hardware.

5. Align articulating jib boom pivot weldment with

attach holes in fly boom assembly. Using a soft head

mallet, install pivot pin #2 into fly boom assembly

and secure with mounting hardware.

6. Align the slave leveling cylinder with attach holes in

articulating jib boom pivot weldment. Using a soft

head mallet, install slave leveling cylinder pin #1

into articulating jib boom pivot weldment and secure

with mounting hardware.

4.10 FOOTSWITCH ADJUSTMENT

Adjust switch so that functions will operate when pedal is

at center of travel. If switch operates within last 1/4 inch

(6.35 mm) of travel, top or bottom, it should be adjusted.

4.11 BOOM LIMIT SWITCHES

Refer to Figure 4-10., Boom Limit Switches for adjust-

ments to be made to the two Boom Limit Switches which

bolt in place on the upright.

A,B,D

C,D

A

B

C

D

Torque to 50 ft.lbs. (68 Nm)

Loctite #242

Torque 250-270 ft. lbs. (339-366 Nm)

Check torque every 150 hours of operation

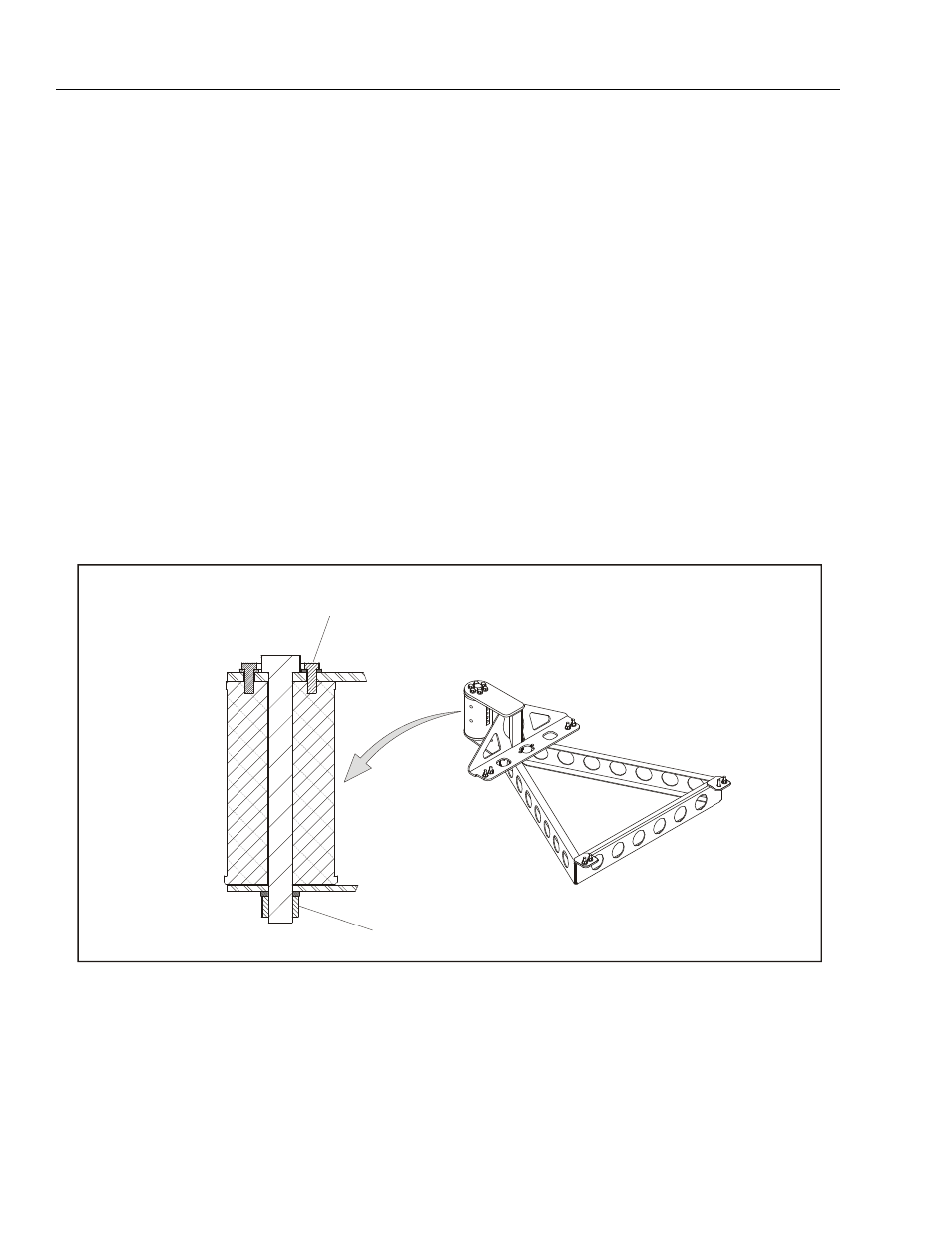

Figure 4-9. Platform Support Torque Values

NOTE: If any rotator bolts are replaced, all bolts

on the rotator should be retorqued.