Rbs alarms and flash codes, Resetting the rbs controller, Maintenance schedule – JLG M400 Service Manual Service Manual User Manual

Page 111: Rbs alarms and flash codes -69

SECTION 3 - CHASSIS & TURNTABLE

3121827

– JLG Lift –

3-69

RBS Alarms and Flash Codes

In the event of an RBS alarm, a flash code will be issued

and an alarm indicated on the analyzer.

Alarms must be reset once the fault has been corrected

(see below).

Resetting the RBS Controller

The RBS can be reset using the analyzer or by disabling

and re-enabling the RBS controller. This will clear any cur-

rent fault condition with the controller.

Maintenance Schedule

Check oil level every 24 hours

Change engine oil and filter every 150 hours

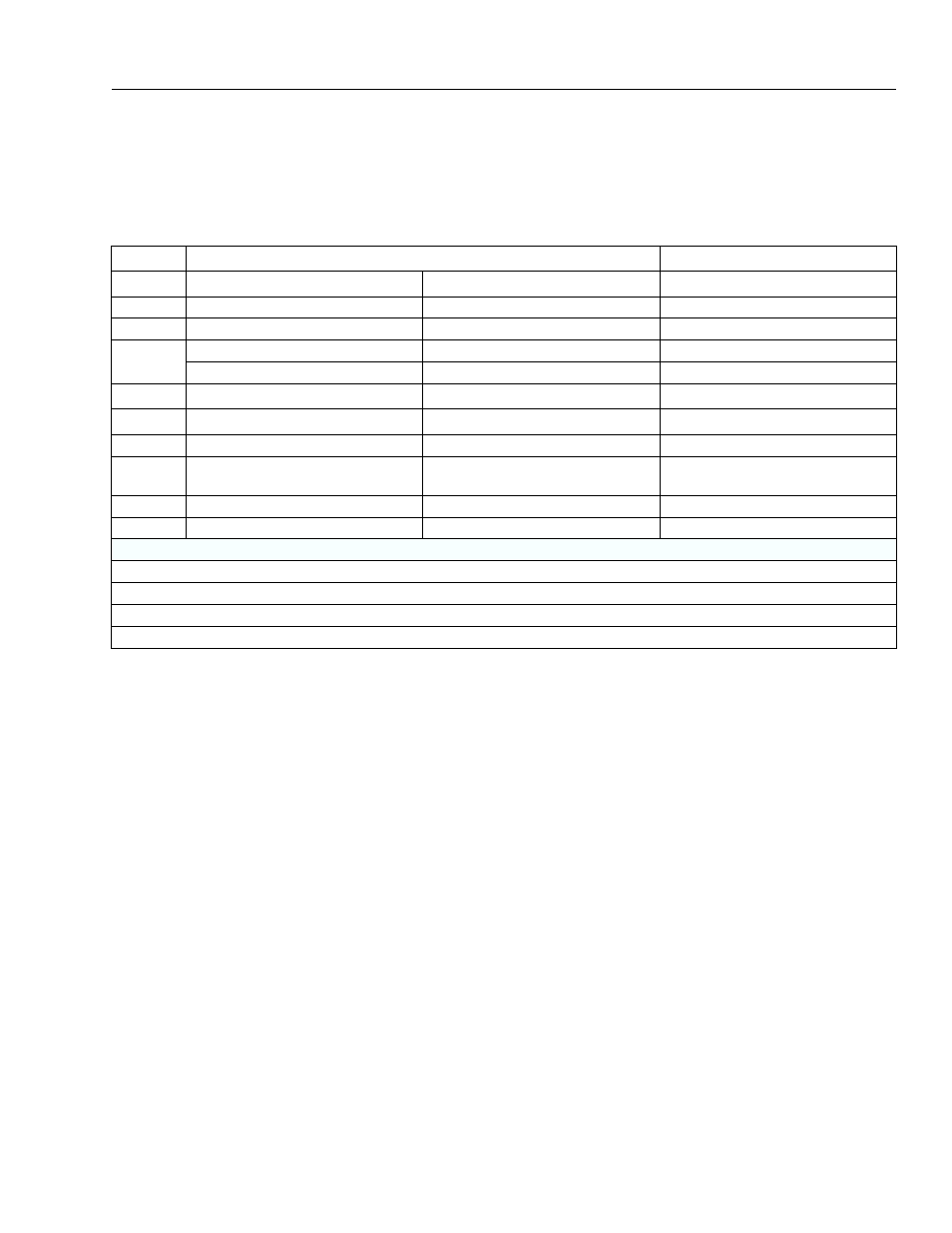

Table 3-10. RBS Alarms and Flash Codes

Flash Code

Problem

RBS Condition

1-1

Low Oil Pressure

1

Below 7psi

Shutdown

1-2

High Engine Temp.

Over248°F(120°C)

Shutdown

1-3

Overspeed

Over 3800 RPM

Shutdown

1-4

Underspeed 1

Below 2000 RPM

Shutdown

Overcrank

3 failed crank cyclesCall to start removed

Call to start removed

1-5

No Speed Signal

2

Shutdown

2-1

Overvoltage

3

Over 63VDC

Shutdown

2-2

Engine Starting System fault 4

Alarm

2-4

Loss Of Voltage Sense

Alternator output less than 1/2 of the system

nominal voltage (58VDC)

Shutdown

steady

Unit Enabled, no faults

Unit can respond to any call to start

-

Unit Off / Disabled

Unit will not respond to any call to start

Notes:

1 Enabled once time delay bypass period has elapsed after engine startup.

2 Delayed to ensure the fault was not momentary.

3 Measured at the alternator output, shutdown is delayed by a factory set period to ensure the fault was not caused by a transient condition.

4 Indicates a problem with the engine start battery, engine magneto or magneto-voltage regulator.