6 supplemental information, 6 supplemental information -16, 15 wheel torque chart -16 – JLG E300 Operator Manual User Manual

Page 86

SECTION 6 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

6-16

– JLG Lift –

3121252

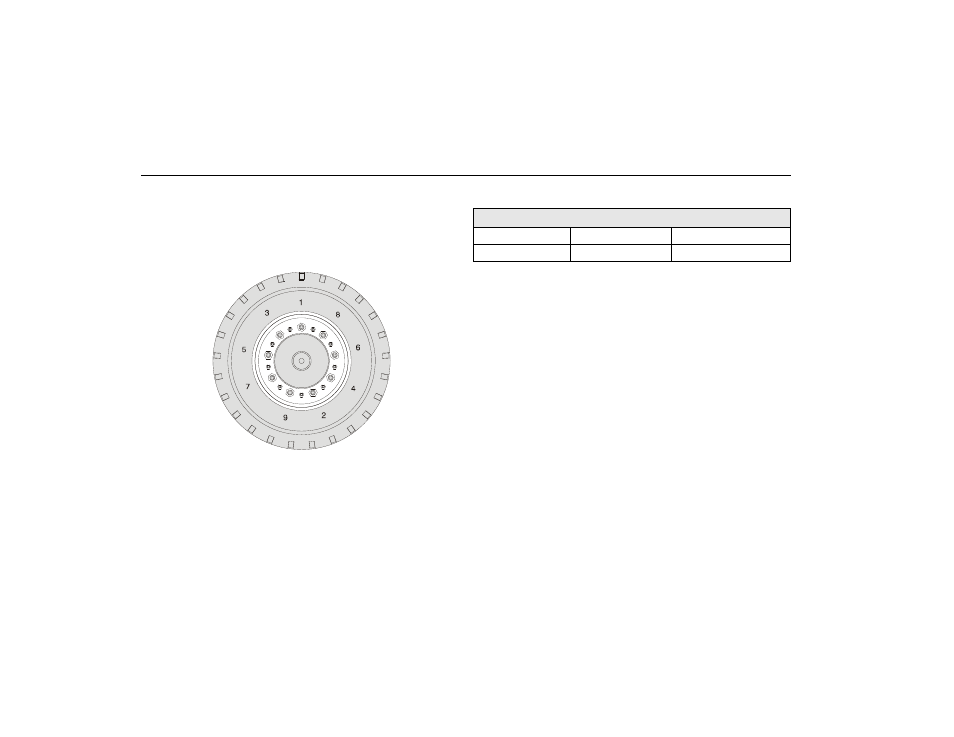

mounting stud holes in the wheels. The proper procedure for

attaching wheels is as follows:

1. Start all nuts by hand to prevent cross threading. DO

NOT use a lubricant on threads or nuts.

2. Tighten nuts in the following sequence.

3. The tightening of the nuts should be done in stages. Fol-

lowing the recommended sequence, tighten nuts per

wheel torque.

4. Wheel nuts should be torqued after first 50 hours of

operation and after each wheel removal. Check the

torque after the first 10 miles, 25 miles, and again at 50

miles. Check periodically thereafter.

6.6 SUPPLEMENTAL INFORMATION

The following information is provided in accordance with the

requirements of the European Machinery Directive 2006/42/

EC and is only applicable to CE machines.

For electric powered machines, the equivalent continuous A-

Weighted sound pressure level at the work platform is less

than 70dB(A)

For combustion engine powered machines, guaranteed

Sound Power Level (LWA) per European Directive 2000/14/

EC (Noise Emission in the Environment by Equipment for

Use Outdoors) based on test methods in accordance with

Annex III, Part B, Method 1 and 0 of the directive, is 104 dB.

The vibration total value to which the hand-arm system is

subjected does not exceed 2,5 m/s

2

. The highest root mean

square value of weighted acceleration to which the whole

body is subjected does not exceed 0,5 m/s

2

.

Table 6-15. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

40 ft lbs (55 Nm)

95 ft lbs (130 Nm)

170 ft lbs (230 Nm)