Piston seal kit installation -6, Tapered bushing installation -6, Seating the tapered bearing -6 – JLG 601S Service Manual User Manual

Page 156

SECTION 5 - HYDRAULICS

5-6

– JLG Lift –

3120866

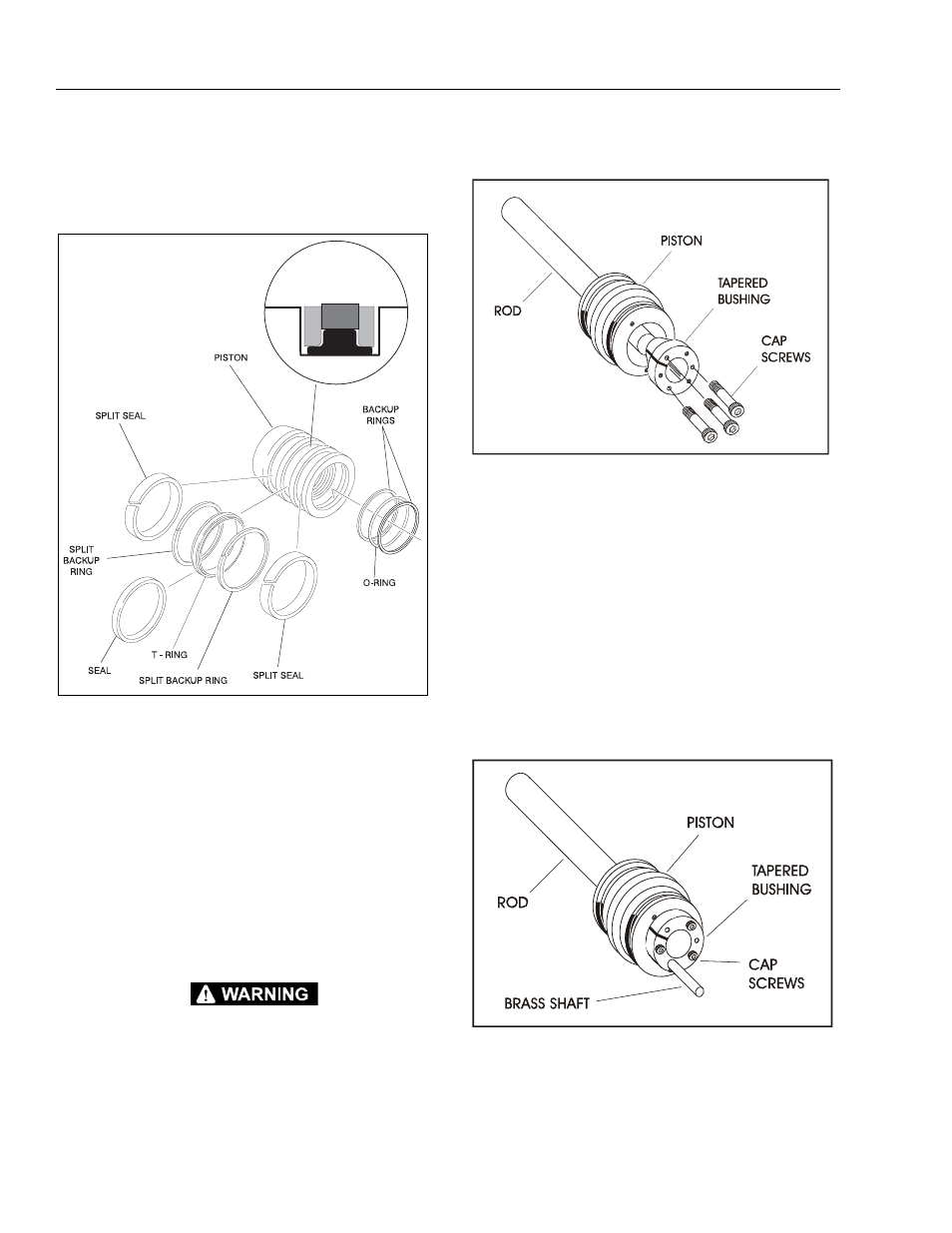

NOTE: The backup rings for the solid seal have a radius on

one side. This side faces the solid seal.(See magni-

fied insert in Figure 5-10.)The split of seals and

backup rings are to be positioned so as not to be in

alignment with each other.

8. Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture as close to piston as

possible.

9. Carefully thread the piston on the cylinder rod hand

tight, ensuring that the o-ring and back-up rings are

not damaged or dislodged.

10. Thread piston onto rod until it abuts the spacer end

and install the tapered bushing.

NOTE: When installing the tapered bushing, piston and mat-

ing end of rod must be free of oil.

WHEN REBUILDING THE MASTER, SLAVE, LIFT, OR TELESCOPE

CYLINDERS, APPLY LOCTITE #242 TO TAPERED BUSHING

BOLTS, THEN TIGHTEN SECURELY. (SEE TABLE 5-1, CYLINDER

HEAD AND TAPERED BUSHING TORQUE SPECIFICATIONS).

11. Assemble the tapered bushing loosely into the pis-

ton and insert JLG capscrews (not vendor cap-

screws) through the drilled holes in the bushing and

into the tapped holes in the piston.

12. Tighten the capscrews evenly and progressively in

rotation to the specified torque value. (See Table 5-1,

Cylinder Head and Tapered Bushing Torque Specifi-

cations.)

13. After the screws have been torqued, tap the tapered

bushing with a hammer (500 to 750 gram) and brass

shaft (approximately 19 mm in diameter) as follows;

a. Place the shaft against the cylinder rod and in

contact with the bushing in the spaces between

the capscrews.

b. Tap each space once; this means the tapered

bushing is tapped 3 times as there are 3 spaces

between the capscrews.

14. Retorque the capscrews evenly and progressively in

rotation to the specified torque value. (See Table 5-1,

Cylinder Head and Tapered Bushing Torque Specifi-

cations.)

Figure 5-10. Piston Seal Kit Installation

Figure 5-11. Tapered Bushing Installation

Figure 5-12. Seating the Tapered Bearing