Inspection, Assembly, Inspection -15 assembly -15 – JLG 601S Service Manual User Manual

Page 145: Removing shaft from housing -15, Removing sleeve from housing -15

SECTION 4 - BOOM & PLATFORM

3120866

– JLG Lift –

4-15

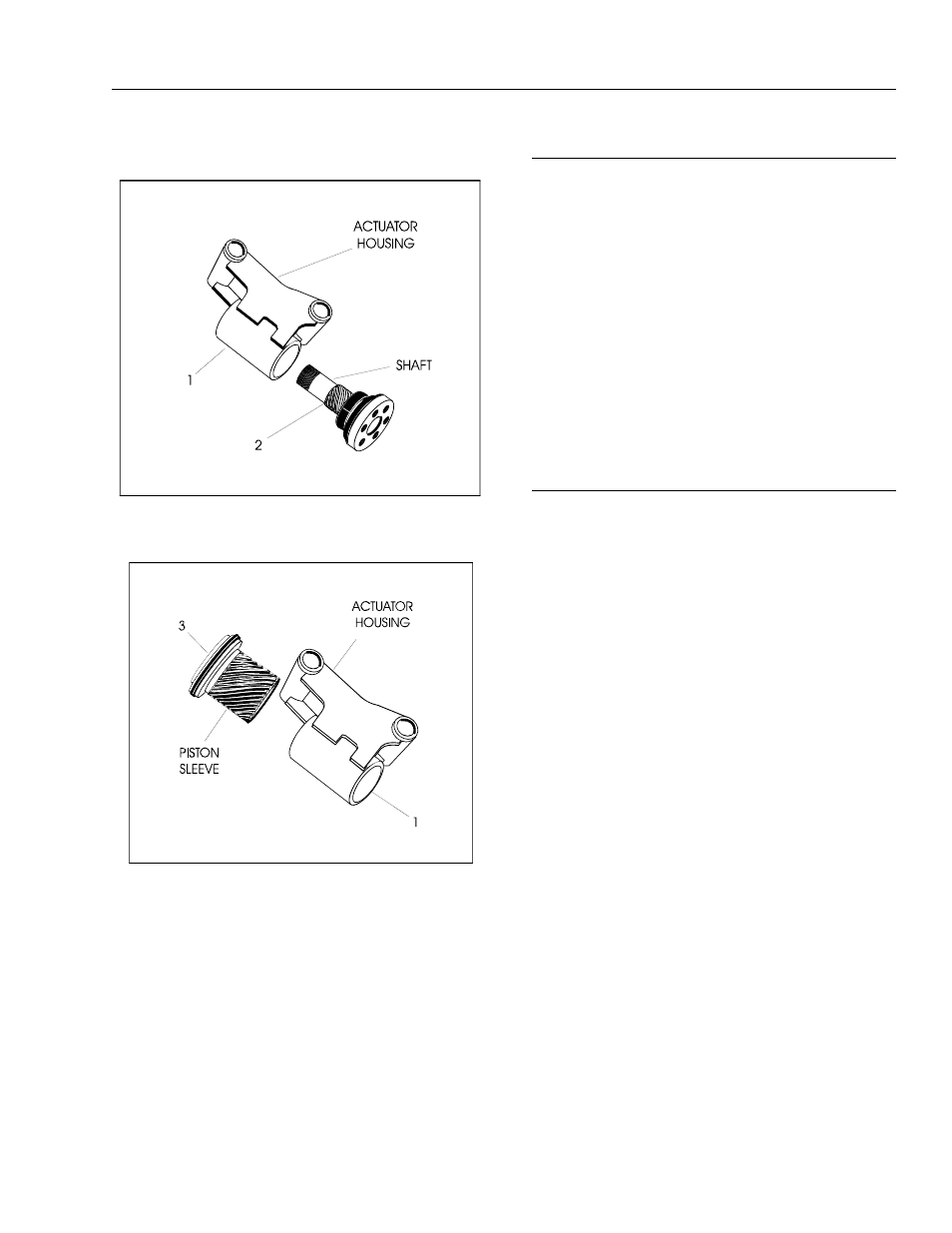

7. Remove the shaft (2) from piston sleeve (3) and the

actuator housing (1).

8. Remove piston sleeve (3) from housing (1).

9. Remove all seals and bearings from grooves. Dis-

card seals.

Inspection

1. Clean all parts thoroughly.

2. Closely inspect all parts for excessive wear, cracks

and chips. Replace parts as necessary.

NOTE: A small amount of wear in the spline teeth will have

little effect on the actuator strength. New spline sets

are manufactured with a backlash of about 0.005 in.

per mating set. After long service, a backlash of

about 0.015 per set may still be acceptable in most

cases, depending on the required accuracy of the

application.

3. Check the ring gear for wear and weld damage to

the pins.

4. Inspect the cylinder bore for wear and scratches.

Assembly

NOTE: Lubricate all seals and o-rings with clean hydraulic

oil prior to assembly.

1. Install new seal (7) and bearing (6) on the piston

sleeve (3).

NOTE: Apply a coat of grease to the thrust ring before slid-

ing onto the shaft.

2. Install new seal (8), thrust ring (10) and bearing (9)

on shaft (2).

NOTE: Apply a coat of grease to the thrust ring before slid-

ing onto the end cap.

3. Install new seals (11), back-up ring (12), cap bearing

(13), bearing packing (14) and thrust ring (10) on

end cap (5).

4. Place the actuator in the vertical position, install the

piston sleeve (3) in timed relation to the housing (1).

Figure 4-22. Removing Shaft from Housing

Figure 4-23. Removing Sleeve from Housing