JLG LSS Scissors User Manual

Page 56

SECTION 6 - SERVICE - (RS)

6-4

– JLG Lift –

3124288

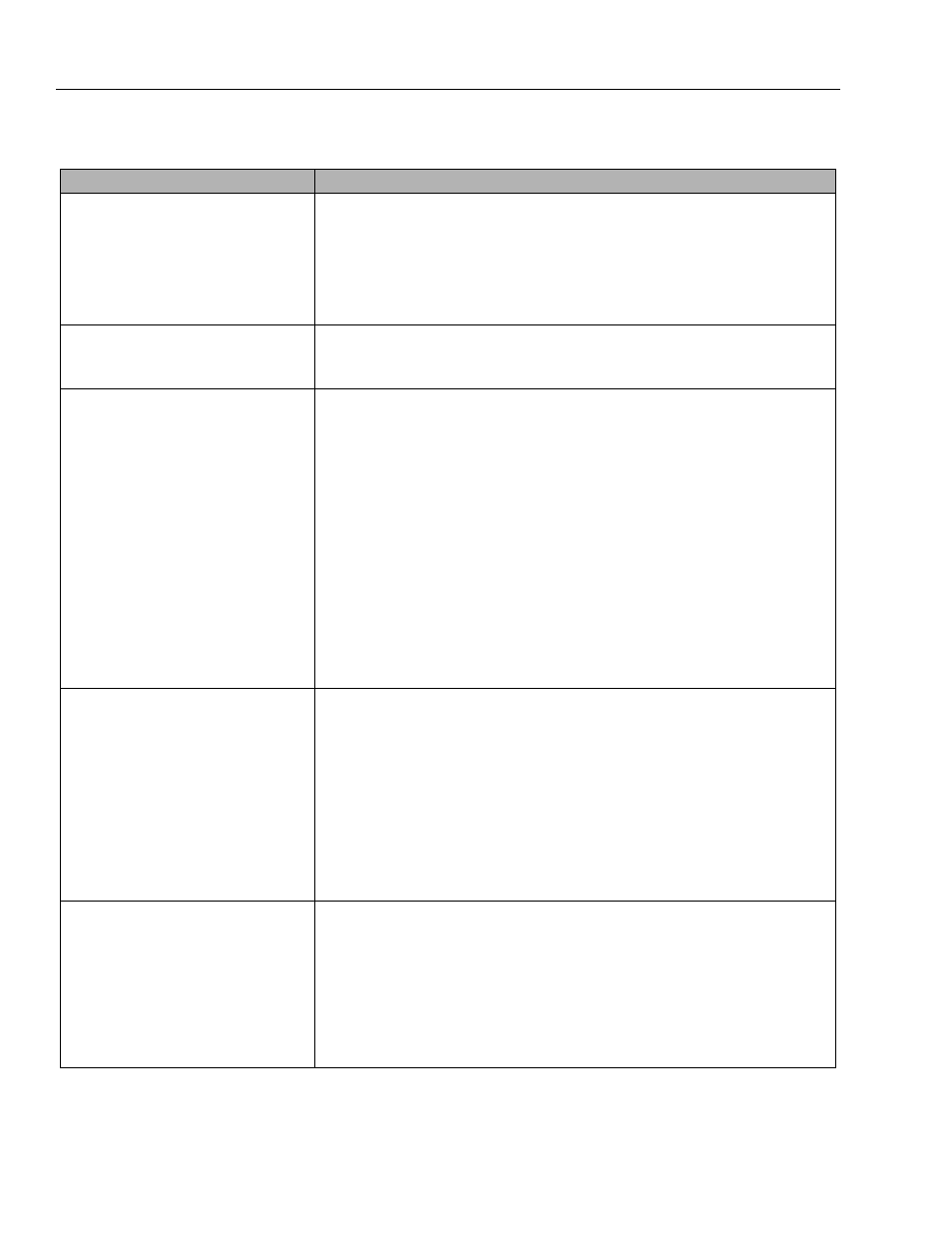

JLG Analyzer displays "MOTION

STOPPED" after the LOAD calibration

steps "LIFT TO MAX ELEV" or "LOWER

TO STOWED".

The platform stopped moving during LOAD calibration.

1. The technician let go of the lift up switch before the machine reached max-

imum elevation during "CAL LOAD: LIFT TO MAX ELEV" or the technician

let go of the lift down switch before the machine became stowed after the

"CAL LOAD: LOWER TO STOWED" step. Re-attempt LOAD calibration

making sure not to disengage the lift up and lift down switch during these

steps.

JLG Analyzer displays "CAL FAIL!"

when attempting to perform a LOAD

Calibration.

The technician has pressed ESC on the Analyzer during the calibration routine.

1. ESC was accidentally pressed during the Calibration procedure. The pre-

viously calibrated values will not be lost. Attempt LOAD calibration again.

The Visual and Audible Overload

Warnings fail to sound when platform

is loaded beyond rated load. Controls

remain functional at Ground and Plat-

form Control Positions.

The Load Sensing System is failing to detect that an overload condition exists or

the Load Sensing system has not been enabled.

1. The Load Sensing System must be enabled within the Host Control Sys-

tem. Connect the JLG Analyzer and enter the Access Level 1 Password

(33271). Navigate to MACHINE SETUP, LOAD submenu. The selection

"CUTOUT PLT" should be displayed for European Community Compliance

(platform controls prevented during overload, ground controls remain

operational). In country- or customer-specific circumstances, the selection

"CUTOUT ALL" is used (platform and ground controls prevented during an

overload).

2. The Load Sensing System requires re-calibration. If the Load Sensing Sys-

tem fails to detect an Overload with 120% load placed in the platform per-

form an ANGLE calibration followed by a LOAD calibration as specified by

the Calibration procedures listed in this document.

3. If a fault is displayed, refer to the portion of this manual that describes

Fault Messages and their causes.

The Visual and Audible Overload

Warnings sound even when platform

is empty. Controls are prevented in the

same manner as when overloaded.

The Load Sensing System has not been calibrated or is experiencing a measure-

ment performance difficulty.

1. The machine is assumed to be overloaded until the Load Sensing System

has been calibrated. Navigate to the CALIBRATIONS menu and perform

an ANGLE calibration followed by a LOAD calibration.

2. The Load Sensing System requires re-calibration. If the Load Sensing Sys-

tem falsely detects an Overload with less than rated load placed in the

platform perform an ANGLE calibration followed by a LOAD calibration as

specified by the Calibration procedures portion of this manual.

3. If a fault is displayed, refer to the portion of this manual that describes

Fault Messages and their causes.

Controls remain functional at the

Ground Control position during an

overload.

The Control at the Platform Control

positions are prevented.

The Host Control System is configured to prevent platform controls only in the

event of overload. Alternately, the Host Control System can be configured to pre-

vent ground and platform controls for country- or customer-specific circum-

stances.

1. Plug the JLG Analyzer in and enter the Access Level 1 password (33271).

Proceed to the MACHINE SETUP, LOAD sub-menu. Set this parameter to

"CUTOUT PLT" to prevent platform controls in the event of overload. Set

this parameter to "CUTOUT ALL" to prevent platform and ground controls

in the event of overload.

Table 6-3. LSS Troubleshooting - RS (Continued)

PROBLEM

POSSIBLE RESOLUTION