JLG 120-SXJ Service Manual User Manual

Page 35

SECTION 3 - CHASSIS & TURNTABLE

3121810

– JLG Lift –

3-7

5.

Inspect o-ring grooves in hub (24) and cover (1) for

burrs or sharp edges. Dress applicable surfaces as

necessary.

6.

Inspect all thrust washer and bearing surfaces for

damage. Repair or replace as necessary.

7.

Inspect all threaded components for damage includ-

ing stretching, thread deformation or twisting.

Replace as necessary.

8.

Inspect planet shafts (15) for scoring or other dam-

age. Replace as necessary.

Assembly

1.

If necessary, assemble hub and shaft assembly.

a. Using a suitable hydraulic press, install bearing

cups (23 and 27) into hub (24).

b. Using the hydraulic press, install bearing cone

(28) onto output shaft (30).

c. Correctly position shaft (30) into hub (24) with

cone (28) in cup (27).

d. Using a suitable shaft support in the hydraulic

press, install bearing cone (22) on shaft (30)

until cone abuts bearing cup (23).

e. Position spacer shim (21) on shaft (30) between

retainer ring groove and bearing cone (22).

f. Using suitable snap ring pliers, install retaining

ring (20) on shaft (30).

g. Using the hydraulic press, install a new seal (29)

over shaft and into hub (24). Ensure that seal is

installed squarely.

h. Check that output shaft (30) rotates freely in the

hub. The oil seal will create a small amount of

drag. By tapping the outside of the shaft with a

soft headed mallet, any excessive tightness will

be reduced.

2.

If necessary, assemble planet carrier assembly (10)

as follows:

a. Apply a light coating of petroleum jelly or multi-

purpose grease to flanged surface of thrust

washers (12).

b. Position thrust washers (12) in carrier (10) with

tang in appropriate carrier cutaway portion.

Ensure that washers are flat against surface on

both sides of carrier.

c. Apply a liberal coating of petroleum or multi-pur-

pose grease to inner diameter of cluster gear

(11).

d. Position spacer (14) at the approximate midpoint

of the gear diameter.

e. On each side of spacer (14), position needle roll-

ers (13) in inner diameter of gear.

f. Position assembled cluster gear (11) into carrier

(10) between the two thrust washers (12).

Ensure that larger gear is on the roll pin side of

carrier.

g. Position planet shaft (15) into carrier hole, with

shaft roll pin hole on same side as carrier roll pin

hole.

h. Continue inserting shaft through thrust washers

(12) and cluster gear 11. Ensure that needle roll-

ers (13) are not displaced.

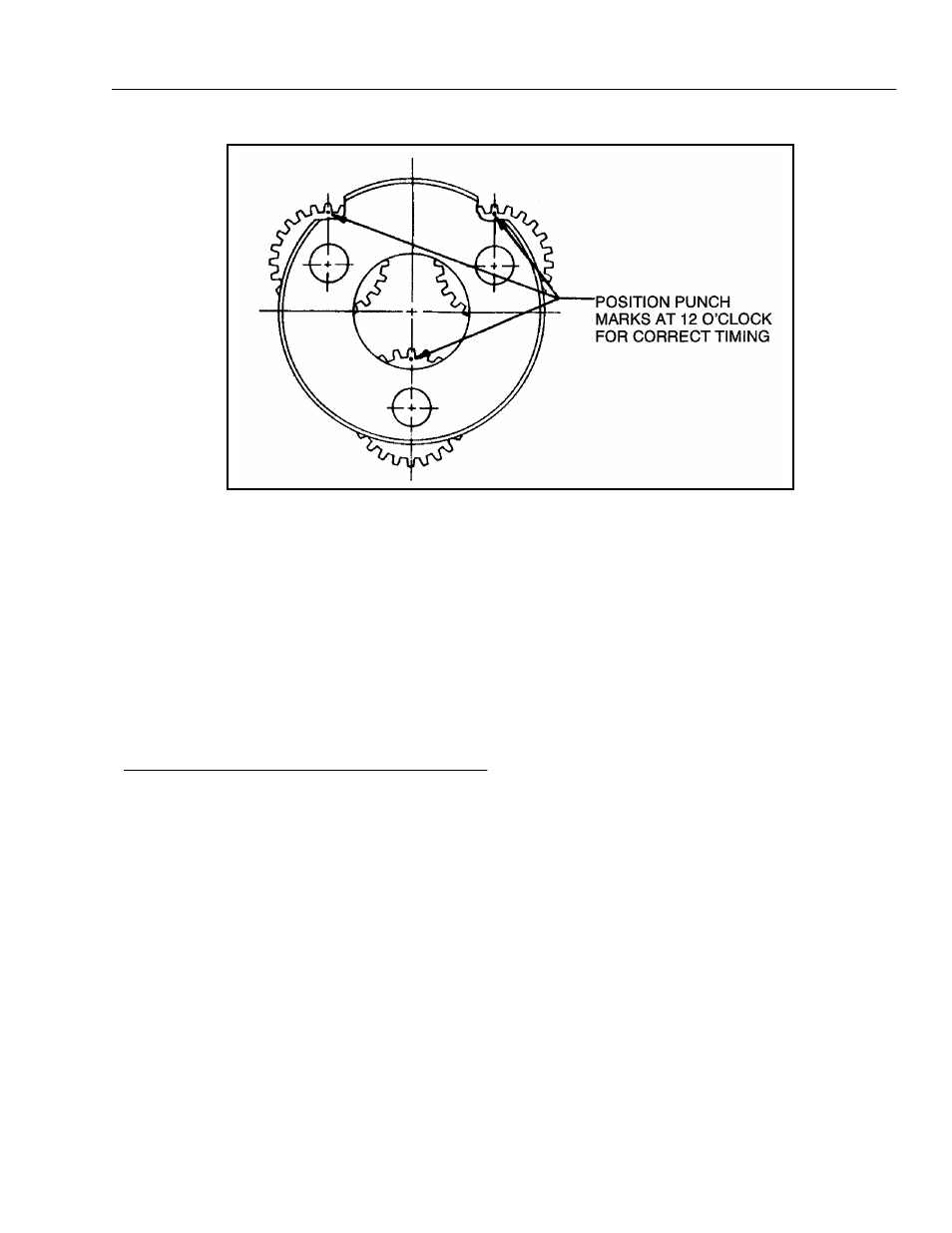

Figure 3-6. Torque Hub Carrier Timing