9 engine coupler, Engine coupler, Coupler removal – JLG 266 LoPro Service Manual User Manual

Page 69: Coupler installation

7.9

266, 307, 266 LoPro

Engine: Deutz BF 4M 2012

16. Check that all hydraulic, electrical, cooling, fuel and

exhaust system connections are correct and

connected tightly.

17. Run engine to normal operating temperature then shut

off the engine. While the engine is cooling, check for

leaks.

18. Allow the engine to cool. Check the radiator coolant

level, and top off with a 50/50 mixture of ethylene

glycol and water. Replace the radiator cap.

19. Check for leaks from the engine, main hydraulic pump

and lines, transmission, hydraulic reservoir and fuel

tank. Check the levels of all fluids and lubricants. Fill

as required.

IMPORTANT: During the full throttle check:

• DO NOT operate any hydraulic function.

• DO NOT steer or apply any pressure to the steer-

ing wheel.

• Keep the transmission in NEUTRAL (N).

20. Obtain and connect an appropriate engine analyzer

or tachometer. Check the engine rpm at full throttle.

If the rpm is not 2370 ±50 rpm, readjust the throttle

limit-stop screw at the throttle pedal within the cab.

21. Purge the hydraulic system of air by operating all

boom functions through their entire range of motion

several times. Check the hydraulic oil level.

22. Check for proper operation of all components.

23. Turn the engine OFF.

24. Install the belly pan.

25. Install the engine cover. Close and secure the cover.

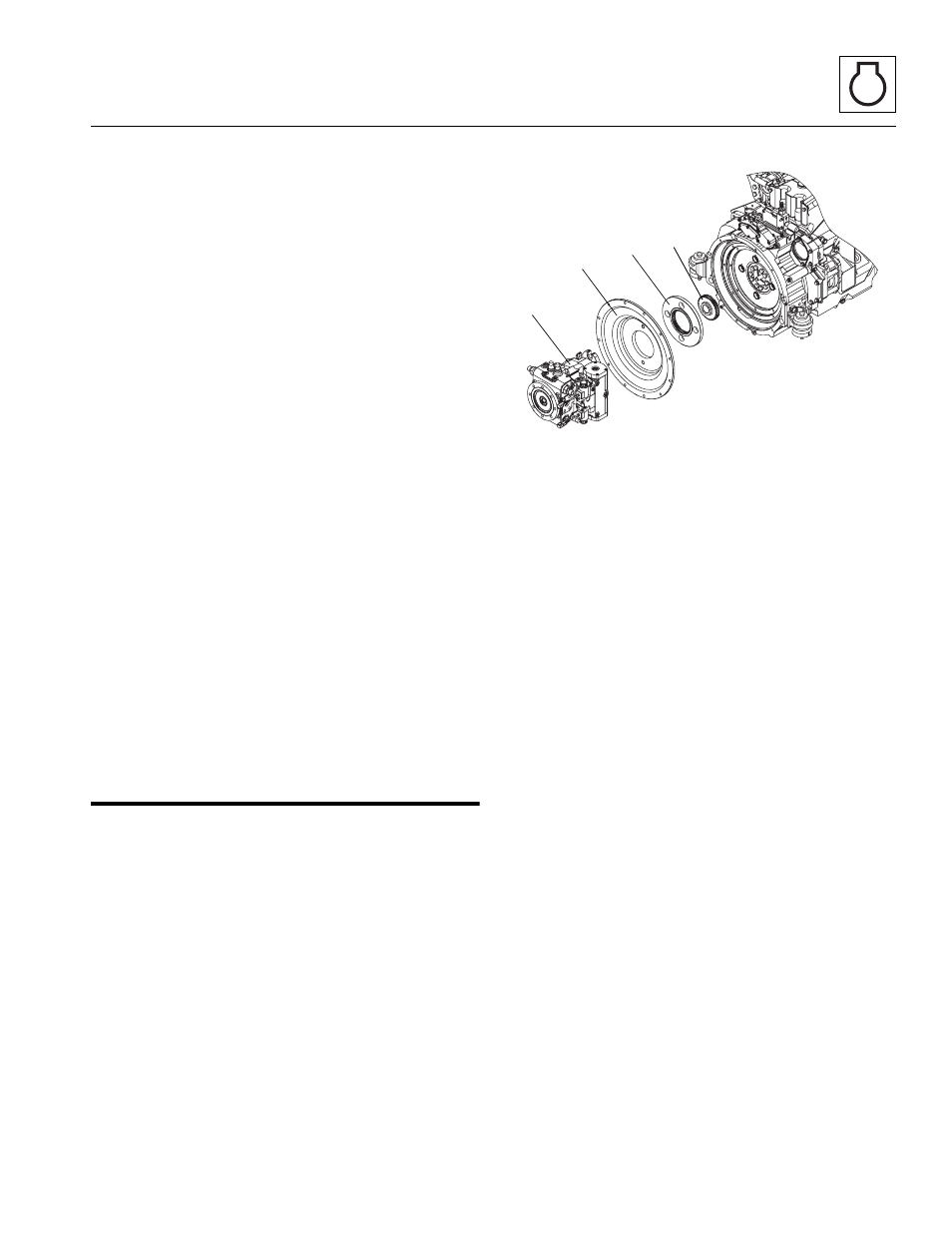

7.9

ENGINE COUPLER

7.9.1

Coupler Removal

1. Remove Hydrostatic transmission (3). Refer to

Section 6.4.1, “Transmission Removal.” Be sure to

follow all described safety guidelines.

2. After transmission has been removed, take out the

12 bolts that attach the Flywheel Cover Plate (4) to

the engine.

3. Pull off the Flywheel Cover Plate to expose the

coupler (5) and the flywheel.

4. Remove the necessary bolts to detach the coupler

and flex plate (6).

7.9.2

Coupler Installation

1. Attach the coupler (5) and flex plate (6) using the

necessary bolts. Torque to 210 Nm (155 lb-ft)

2. Bolt on the Flywheel Cover Plate (4) over the coupler

and flywheel. Torque bolts to 50 Nm (37 lb-ft).

3. Reattach the hydrostatic transmission (3). Follow all

guidelines in Section 6.4.3, “Transmission

Installation.”

MAH0630

3

4

5

6