JLG 3246E2 ANSI Operator Manual User Manual

Page 24

SECTION 2 - PREPARATION AND INSPECTION

2-10

– JLG Lift –

3120736

Key To Lubricants:

MPG - Multi Purpose Grease

HO - Hydraulic Oil - Mobilfluid 424

TO AVOID PERSONAL INJURY, USE SAFETY PROP FOR ALL

MAINTENANCE REQUIRING PLATFORM TO BE ELEVATED.

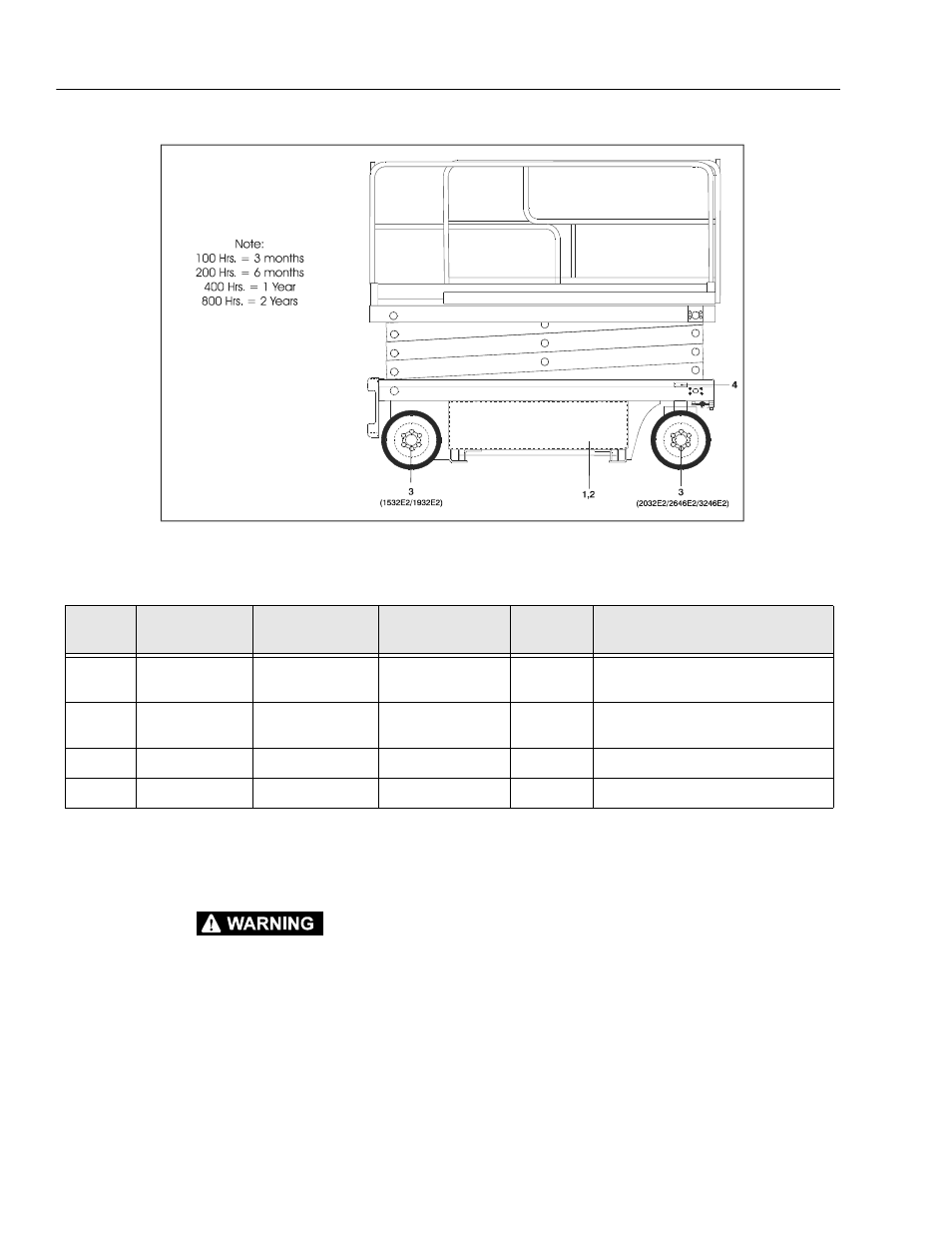

Table 2-2.Lubrication Chart

INDEX

NUMBER

COMPONENT

NO/TYPE LUBE

TYPE

LUBE METHOD

INTERVAL-

HOURS

COMMENTS

1

Hydraulic Oil

Fill Cap/Drain Plug

HO - Check HO Level

HO - Change HO

8/800

Check oil level every 8 hours.

Change oil every 800 hours

2

Hydraulic Filter Ele-

ment

N/A

N/A

50/400

Change filter after first 50 hours of operation,

then every 400 hours thereafter (1 year).

3

Wheel Bearings

Front or Rear Wheels

MPG - Repack

800

2 years

4

Kingpin Housing

Grease Fittings

MPG - Pressure Gun

100

3 months

Figure 2-3. Lubrication Diagram

NOTE: Be sure to lubricate like items on each side of

the machine.

Recommended lubricating intervals are based

on machine operations under normal condi-

tions. For machines used in multi-shift opera-

tions and/or exposed to hostile environments

or conditions, lubricating frequencies must be

increased accordingly.

NOTE: On all machines built before serial number

0200082630, operate lift function through one

complete cycle before checking oil level. Oil

level should be at the full mark or within 1/2"

below the full mark. On machines built after,

and including, serial number 0200082630

check oil level to insure proper level .