23 pq controllers, Pq controllers -48, Trim adjustment (prior to s/n 38697) -48 – JLG 120HX Service Manual User Manual

Page 70: Function speeds -48

SECTION 2 - PROCEDURES

2-48

– JLG Lift –

3120819

2.23 PQ CONTROLLERS

NOTE: The following procedures are to be used as a begin-

ning basis for controller adjustment. After completing

the procedure, final adjustments are to be made

based on the machines function speed.

TRIM Adjustment (Prior to S/N 38697)

1.

Perform the following checks with ignition power to

the platform, with the engine NOT running.

1.

Install ammeter capable of measuring from zero to 2

amps in series with either valve coil B or D.

2.

Position IGNITION/EMERGENCY STOP switch to

ON, but do not start engine.

3.

Using a screwdriver, adjust the ramp trimpot coun-

terclockwise 25 turns or until the trimpot clicks.

4.

Depress footswitch.

5.

Operate controller until trailing edge of slide lock is

even with housing lock notch. Hold control handle in

that position.

6.

Check the mA reading in the opposite direction.

7.

Operate the controller until the trailing edge of the

slide lock is even with the housing lock notch. Hold

the control handle in that position. Check the mA

reading.

8.

Verify step 7 and step 8 mA readings are within 0.50

mA of each other. If the readings are within toler-

ance, proceed to step 12.

9.

If the readings in step 9 were not within tolerance,

Loosen the setscrew located in the gear on the

potentiometer shaft of the controller. Using a screw-

driver, adjust the potentiometer very slightly in either

direction. Tighten the setscrew on the gear and

recheck for the proper mA readings. Repeat this

step until the proper adjustment is obtained.

10.

Place the creep toggle switch in the off position.

11.

Using correct size common blade screwdriver,

adjust LO trimpot until ammeter indicates the proper

value as shown in Table 2-4, Function Speeds.

Clockwise rotation of trimpot adjust screw increases

ammeter; counterclockwise rotation decreases

ammeter reading.

12.

Operate controller in the same direction as in step 6

to the full extent of its travel and hold handle in that

position.

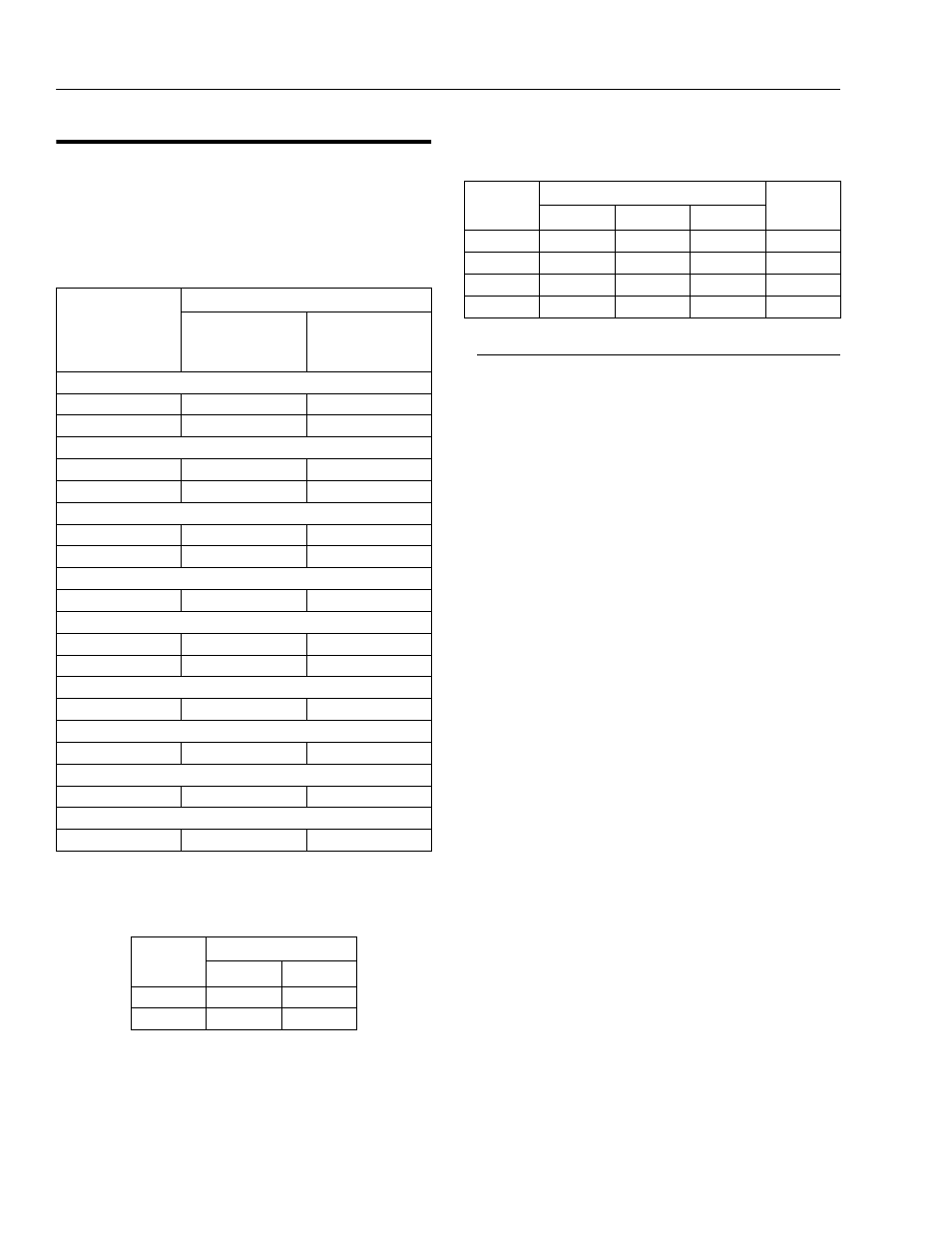

Table 2-4. Function Speeds

Function

Function Speed

In Seconds

(Prior to S/N

38697)

In Seconds

(S/N 38697

to Present)

Telescope

Extend

132-170

80-100

Retract

140-175

75-100

Lift

Up

125-160

85-100

Down

108-132

75-100

Extend-A-Reach

Up

15-25

15-25

Down

15-25

15-25

Swing Speed

Full 360

160-200

160-200

Platform Rotation

Left

20-30

20-30

Right

20-30

20-30

Ground to 120’

257-330

165-200

From 120’ to Ground

248-307

150-200

Ground to 120’ to Ground

505-637

315-400

Drive Speed

46-56 @ 200ft.

46-56 @ 200ft.

Table 2-5. Platform Controller Settings (Prior to S/N

38697)

Function

Settings in mA

Lo

Hi

Lift

300

500

Swing

300

500

Table 2-6. Platform Controller Settings (S/N 38697 to

Present)

Function

Settings in mA

Ramp

Turns

Lo

Mid

Hi

Lift

200

400

1100

6

Swing

200

400

1100

6

Drive

40

70

180

10

Flow Control

170

N/A

1000

N/A