Attachments, Interfaces and outputs – IKA KS 3000 ic control User Manual

Page 20

20

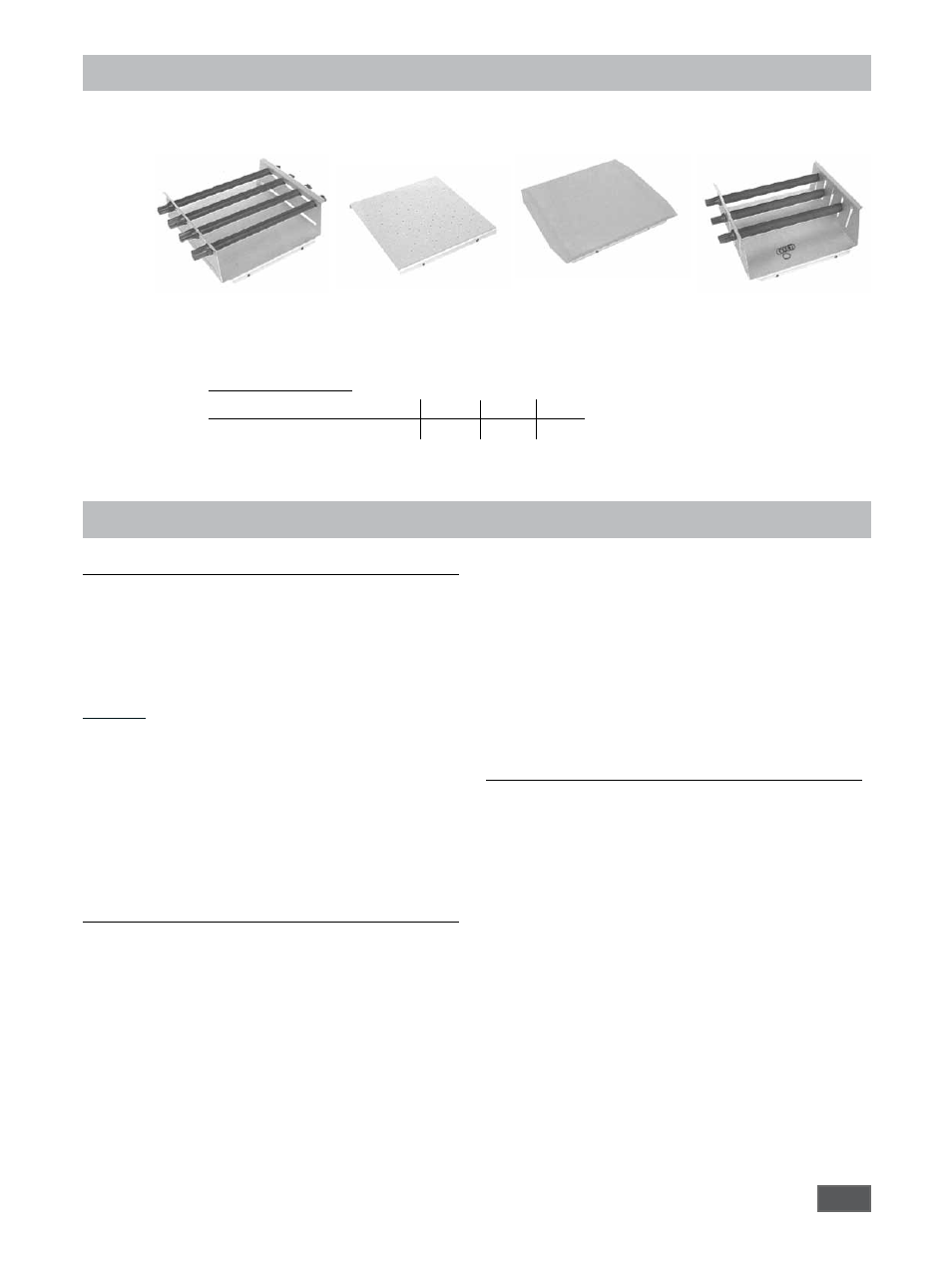

Attachments

AS 260.1

Universal attachment

AS 260.2

Bracket attachment

AS 260.3

Bowl attachment

AS 260.5

Separating funnel attachment

The following attachments are offered as accessories

The attachments are affixed to the shaking table using the four clamping screws provided.

Load (standard values)

Load / kg

1

3

5

7,5

Max. speed / rpm

500

400

300

120

Interfaces and outputs

USB interface

The Universal Serial Bus (USB) is a serial bus system for connec-

ting the KS 3000 to the PC. Devices with USB capabilities can be

connected and disconnected whilst in operation (hot-plugging);

connected devices and their properties are also detected automa-

tically.

The USB interface is used in conjunction with labworldsoft

®

for

operation in “Remote” mode

Installation

Connect the KS 3000 to the PC using the USB data cable. The KS

3000 will then transmit information to the Windows operating

system to tell it which device drivers are required. Windows will

then either:

- Load the driver

- Install the driver automatically, if it is not already installed

- Prompt the user to perform a manual installation

- In this case, select the appropriate download from the IKA

Internet product page.

Configuration

The unit can be controlled from an external PC (using the dedica-

ted software labworldsoft) via the RS 232 C serial interface / USB

fitted to the unit.

To increase safety when controlling the shaking unit from

a PC, enable the watchdog function for monitoring the

continuous serial data flow (see section watchdog function)

• The functions of the inteface lines between laboratory instru-

ment and automation system are selected from the specfied

signals of the EIA-standard RS 232 C, corresponding with DIN

66020 Part 1. The allotment of the bushing can be taken from

illustration.

• For the electrical properties of the interface lines and for the

allotment of the signal status, standard RS 232 C, correspon-

ding with DIN 66259 Part 1 applies.

• Transmission method:

Asynchronous signal transmissi-

on in start-stop-operation.

• Mode of transmission:

Fully Duplex

• Character format:

Character imaging acc. to data

format DIN 66022 for start –

stop operation. 1 start bit;

7 character bits; 1 parity bit-

[straight (even)]; 1 stop bit..

• Transmission speed:

9600 Bit/s

• Access method:

Data communication from sha-

ker to computer is only possible

on demand of the computer.

Instruction syntax

Here applies thje following:

• The instructionsare generally sent from the processor (master)

to the laboratory instrument (slave).

• The laboratory instrument exclusively sends on demand of the

processor. Even error codes cannot be spontaneously communi-

cated from the laboratory instrument to the processor (automa-

tic system)

• Instructions and parameters as well as subsequent parameters

are separated by at least o n e blank. (Code: hex 0x20)

• Each individual instruction including parameters and data as

well as each reply are terminated with CR LF (Code: hex

0x0D and 0x0A) and have a maximum lenght of 80 characters.

• The decimal separator in a floating point number is the point.

(Code: hex 0x2E)

The above statements largely correspond with the recommenda-

tions of the NAMUR-Assocation (NAMUR-recommendations for

the design of electric plug connections for the analog and digital

signal transmission to labortory - MSR individual units. Rev. 1.1).