Burnham V7 SERIES User Manual

Page 7

7

SECTION II: KNOCKDOWN BOILER ASSEMBLY

A. REMOVAL OF BARE BOILER FROM SKID

1. Boiler is secured to base with 4 bolts, 2 on front and

2 on rear, see Figure 2. Remove all bolts.

2. Tilt boiler to right and to rear. Using right rear leg

as pivot, rotate boiler 90° in a clockwise direction,

and lower left side of boiler to floor. Tilt boiler and

remove crate skid.

Note: If Boiler is Packaged Go To Section III

Figure 2

B. MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

C. TEST BOILER FOR LEAKS before installing

controls, trim, and jacket, and before connecting to

heating system.

1. Loosen nuts on tie rods until only finger tight.

2. Install pressure gauge (at least 30 P.S.I. capacity), a

hose to the city water and a valve in the supply

tapping. Plug remainder of tappings.

3. Fill boiler with water and apply a pressure of at

least 10 pounds but no more than 30 pounds gauge

pressure.

4. Examine Boiler carefully inside and outside for

leaks or damage due to shipment or handling.

D. DRAIN WATER FROM BOILER. Remove gauge,

valve and plugs from those tappings to be used. Leave

other tappings plugged or bushed according to Figure

4.

E. INSPECT JOINTS BETWEEN SECTIONS. All joints

are factory sealed. If there are any spaces due to

shipment or handling, seal them with boiler putty.

F.

INSPECT FLUE COVER PLATES for tightness. If

loose, retighten mounting hardware. If flue plate or

sealing insulation is damaged repair or replace as

needed.

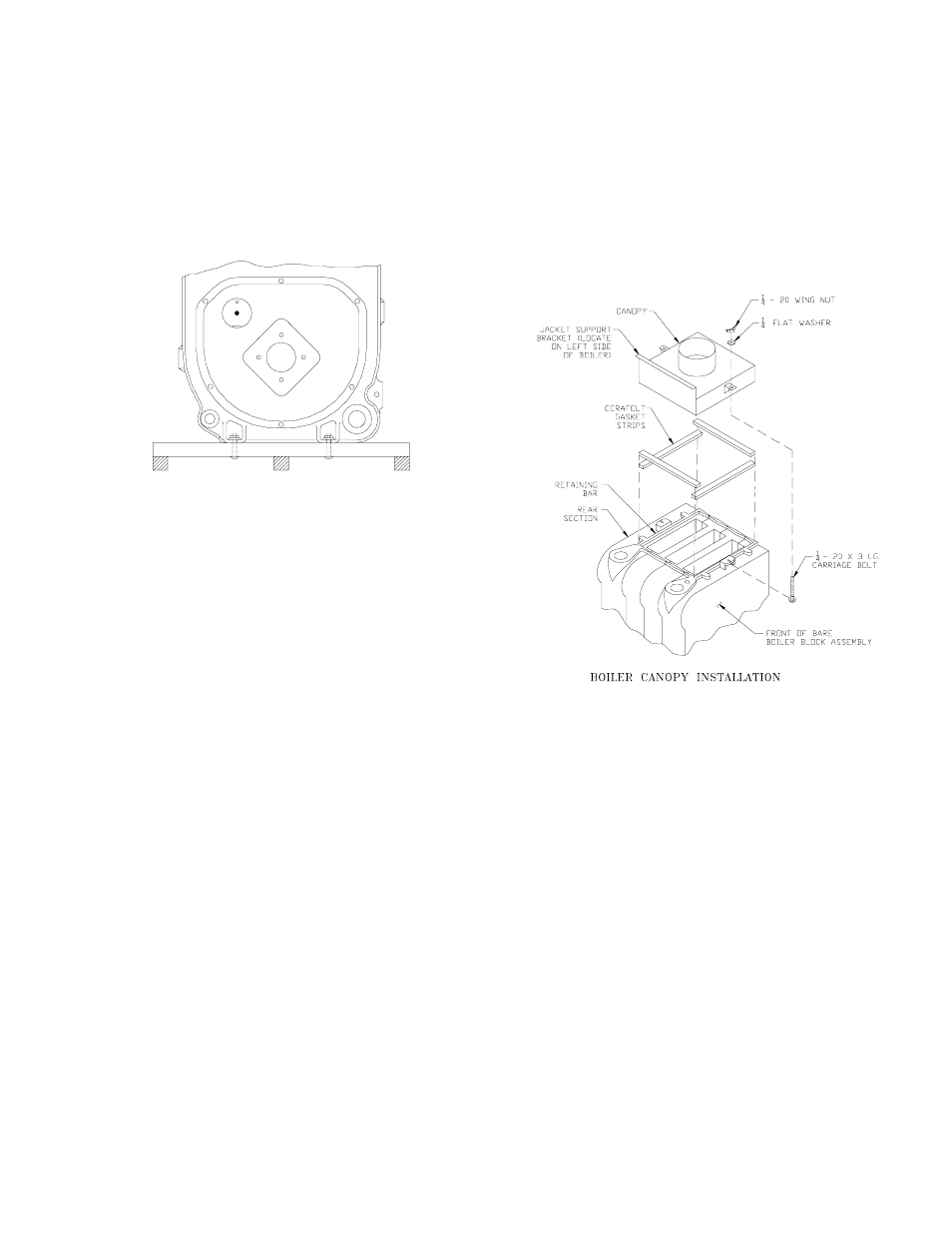

G. INSTALL AND SECURE CANOPY with cerafelt

gasket and hardware provided to ensure gas tight seal

— see Figure 3.

1. Cut two (2) strips 13 ¾” lg. from the roll of cerafelt

gasket insulation. Place one (1) strip across the top

of the front section and the other across the rear

section as shown in Fig. 3. Place gaskets so as not

to allow any flueway blockage.

2. Cut the remainder of the roll into two (2) equal

pieces. Place each piece along the sides, allowing

the ends to overlap the front and rear pieces.

Do not allow any flueway blockage.

3. Position canopy body within the retaining bar

which borders the flueway openings on top of the

bare boiler block assembly.

IMPORTANT: Jacket support bracket must be

facing left side of boiler — see Figure 3.

4. Secure canopy to boiler with two (2) 1/4" - 20 x 3"

lg. carriage bolts, 1/4" flat washers and 1/4" - 20

wing nuts provided.

H. INSTALL the following steam or water trim that

would be concealed or inaccessible after flush jacket is

installed, see Figure 4 for boiler tapping locations and

usage.

1. STEAM BOILER — Top tappings:

a. Tapping "L" — Install 2" plug in rear section

top supply tapping on boiler sizes V73 thru

V75.

b. Tapping “M” — Install ¾” coupling and ¾” x

8” long nipple into ¾” tapping located next to

front section top supply tapping — all boiler

sizes.

2. WATER BOILER — Top tappings:

a. Tapping “L” — Install 2” plug in rear section

top supply tapping on boiler sizes V73 thru

V79.

Figure 3