Burnham V7 SERIES User Manual

Page 10

10

manner as rating label.

c. On steam boilers, install the Lowest Permissible

Water Level Plate, Form No. 1204 (shipped in

Steam Trim Carton), on the jacket right side

panel. Align the two holes in the plate with the

two 1/8” dia. holes located near the front edge,

in line with the lower sight glass tapping, and

secure with #8 x ½” lg. sheet metal screws.

J.

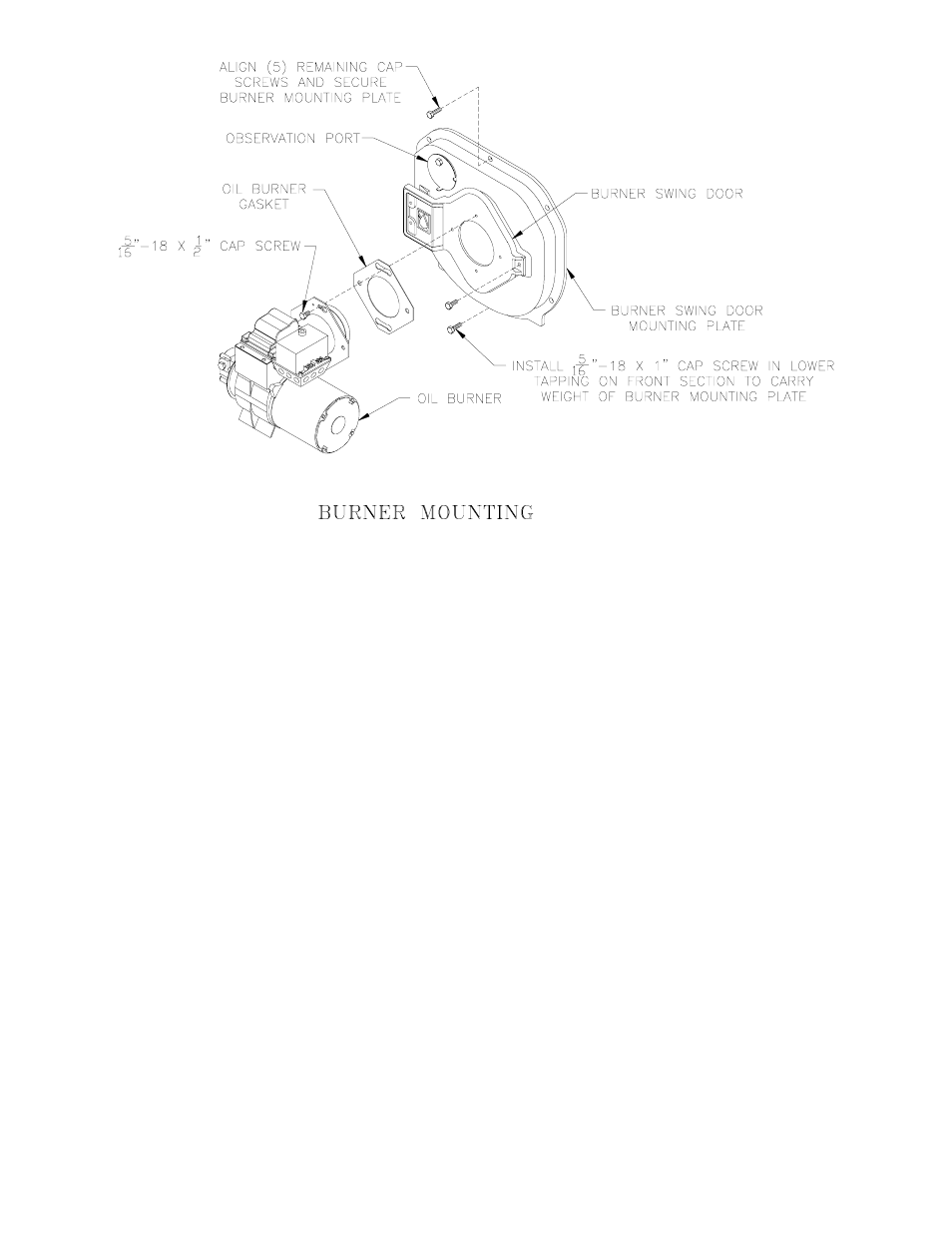

INSTALL OIL BURNER (See Figure 6).

1. Check target wall and cerafelt blanket in

combustion chamber. If any damage or movement

occurred during shipment, repair or replace as

needed.

2. Check the burner mounting plate and swing door

insulation pieces for damage and adhesion. If

damaged, replace insulation. If loose, re-attach with

RTV 732 or 736 silicone caulk.

3. Engage bottom slot on burner mounting plate with

matching bolt in bottom tapping of front section.

Align mounting holes and fasten the mounting

plate to the boiler sections with (5) five 5/16” bolts

and washers removed in step 8a. Fully tighten all

bolts.

4. Place burner flange gasket on burner swing door

and thread two 5/16” x ½” long bolts into vertical

set of holes approximately three full turns.

5. Insert oil burner air tube into the opening of the

burner swing door. Align keyhole slot with vertical

set of bolts, engage hex head of bolts and rotate

burner to the left. Install two remaining 5/16” x ½”

long bolts in horizontal sets of holes. Level burner

and fully tighten all bolts.

K. INSTALL STEAM BOILER TRIM AND CONTROLS

(See Figures 1C & 4).

1. Thread the combination pressure/vacuum gauge

into the ¼” tapping. Tighten with wrench applied

to the square shank of the gauge. Do not apply

pressure to the gauge case — this might destroy the

calibration of the gauge.

2. Thread 1½” x ¾” bushing and a ¾” drain cock into

the 1½” tapping located in the lower right corner of

the front casting. Tighten with wrench.

NOTE: Lower rear section tapping “H” is used for

standard condensate return on steam boilers.

3. Thread safety relief valve, as shown in Figure 1C,

into 3/4" coupling and 3/4” x 8” nipple previously

installed in step H. Tighten with wrench.

NOTE: Pipe discharge as shown in Figure 8.

4. Install probe type LWCO if so equipped. Thread

probe into ¾” tapping located on the front section

directly above the protectorelay on the oil burner.

Read the manufacturer’s instructions packed with

the probe LWCO for proper pipe dope application.

DO NOT use Teflon tape on probe threads. Use of

teflon can render the probe LWCO inoperational.

Slip the LWCO control over the probe and clamp in

place. Connect the wire(s) between the probe and

control per the manufacturer’s instructions. Install

Figure 6