Snorkel T85J User Manual

Page 65

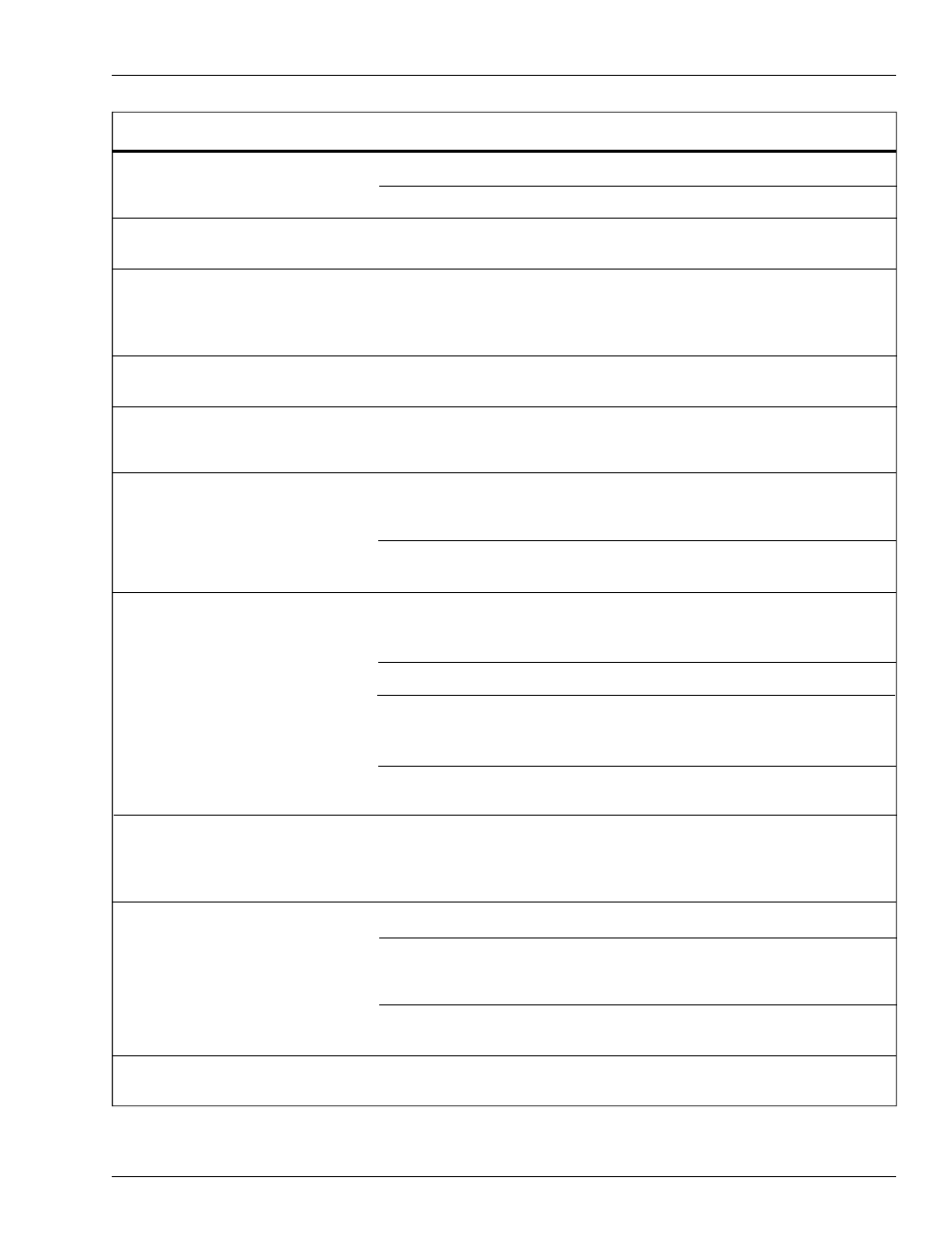

Chapter 11 – Troubleshooting

TB80/TB85J Fixed Axle – 0112792

61

Symptom

Can not reach maximum drive

speed of 3 mph (4.8 km/h).

Wheels will not turn when winch-

ing.

Steer wheels do not turn when the

drive joystick is moved to the right

or to the left.

Steer wheels do not turn right or

left – machines with tow option.

Tilt alarm does not work.

Circuit breaker will not reset.

Electrical outlet does not work.

Improper AC generator output

voltage.

Hydraulic fluid temperature 200°F

(93°C) or more.

Severe hydraulic leak.

Possible Cause

Booms are not retracted and lowered.

Drive range switch is in LO or MID.

Drive hubs are engaged.

The drive joystick must be in the for-

ward or reverse position for the steer-

ing wheels to turn or the main boom

must be stowed.

Tow kit steering float valve is open.

Booms are stowed.

Electrical circuit has not had time to

cool.

Electrical system malfunction.

Power supply not plugged in.

GFCI is tripped.

Machine/generator switch not in the

generator position.

Power cord to platform is not plugged

into the AC generator.

Hydraulic oil is cold and thick.

Prolonged boom operation or driving.

High pressure fluid return to reser-

voir caused by kinked or twisted

hose.

Hydraulic system component failure.

Failure of hose, tube, fitting, seal,

etc.

Corrective Action

Fully retract and lower the boom.

Place the switch in the HI position.

Turn drive wheel disconnect plates

around so nipples point inward.

Push the drive joystick slightly for-

ward or backward when operating

steer right or left.

Close the steering float valve.

Normal operation. The tilt alarm is op-

erational when the booms are near

horizontal.

Wait a minute or two for circuit to

cool, then push circuit breaker but-

ton in to reset.

Do not operate machine until repairs

are made.

Plug a source of power into the

power-input connector on the wiring

box.

Push reset button on outlet.

With engine running, place the ma-

chine/generator switch in the genera-

tor position.

Plug power cord into the outlet on the

left side of the lower control panel.

Use cold weather hydraulic oil as rec-

ommended for weather conditions.

Warm oil before operating the ma-

chine.

Stop operation until fluid cools.

Remove the kink or twist from the

hose. Let fluid cool before operating.

Stow the machine and do not oper-

ate until repairs are made.

Do not operate machine until repairs

are made.