Daily maintenance, Fueling, Gasoline – Snorkel AB62 User Manual

Page 16: Diesel, Hydraulic fluid, Fueling hydraulic fluid

Page 14

104044-001 AB62 Work Platform - Operator Manual

Daily Maintenance

D

AILY

M

AINTENANCE

F

U E L I N G

Stop the engine and turn off the key switch before re-fueling.

Figure 9:

Fuel Tank

G

ASOLINE

1. Open the left turret cover, then open the fill cap.

2. Fill to capacity with unleaded gasoline only.

• Fuel tank full capacity is 159 liters (42 US gallons).

3. Install the cap.

D

IESEL

1. Open the left turret cover, then open the fill cap.

2. Fill to capacity with diesel motor fuel only, grade #1-D or #2-D.

Use distillate fuel only; do not use residual or blend.

• Fuel tank full capacity is 159 liters (42 US gallons).

3. Install the cap.

LPG (

OPTION

)

1. Unfasten the coupler from the LPG valve on the tanks.

2. Remove the LPG tanks from the machine and fill according to ASME, NFPA and local standards.

IMPORTANT: When using propane, use clean, water free liquid petroleum gas, preferably from a bulk storage tank.

W A R N I N G

!

!

If you smell propane, close the supply valve on both tanks immediately until you have located and

corrected the leak.

H

Y D R A U L I C

F

L U I D

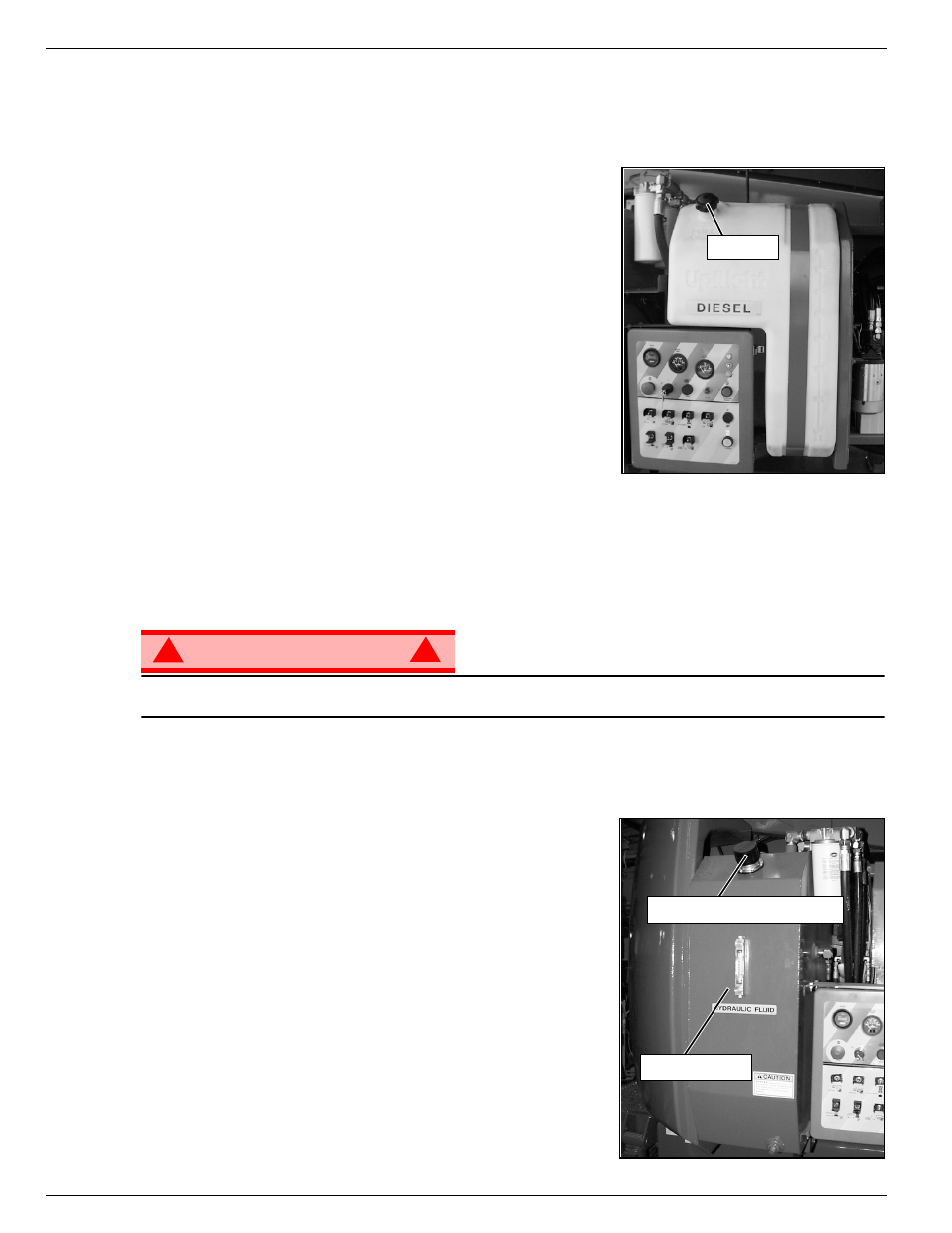

Figure 10:

Hydraulic Fluid Tank

1. Open the turret cover and check the fluid level at the sight

gauge with the boom stowed and retracted; engine running or

stopped.

NOTE: Never add hydraulic fluid if the boom is elevated or extended.

2. If necessary, fill to capacity with clean ISO compatible hydraulic

fluid.

• Normal Temperature, above 0° C (32° F) __ ISO #46.

• Low Temperature, below 0° C (32° F) ____ ISO #32.

• Extreme Temperature, below -17° C (0° F)

ISO #15.

3. Clean the area around the cap before opening.

4. Open the filler/breather cap to add hydraulic fluid.

5. Install the cap.

Fuel Cap

Hydraulic Fluid Filler Cap

Level Gauge