Fasteners upper control station, Guardrail system, Lanyard anchors – Snorkel AB46JRT User Manual

Page 35: Operating controls

Chapter 7 – Prestart Inspection

AB46JRT – 0260071

31

To inspect the slide pads:

1. Use the lower controls to position the main boom near

horizontal. Extend the tip boom about 1

′ (30 cm).

2. Visually inspect the slide pads to make sure they are

securely fastened to the main boom.

3. Inspect the surface where the pads contact the tip

boom. The paint must be in place with no signs of

bare metal.

Fasteners

To inspect the component fasteners:

1. Visually inspect all fasteners to see that none are

missing or loose.

2. Inspect all of the bolts, nuts, rollpins, collars, and

snap rings that connect the booms and cylinders.

They should all be present, tight, and not damaged

in any way.

3. Raise the riser boom to access the inner race rotation

bearing bolts in the turntable (refer to Figure 7.12).

The outer race bolts can be viewed through the open-

ings in the turntable. Rotate the turntable to inspect

all of the outer race bolts.

Figure 7.12 – Rotation Bearing Bolts

4. Inspect the inner and outer race rotation bearing

bolts to ensure that none are missing, damaged, or

loose.

Upper Control Station

Inspect the platform and upper controls, after verifying all

functions operated properly from the lower controls.

Guardrail System

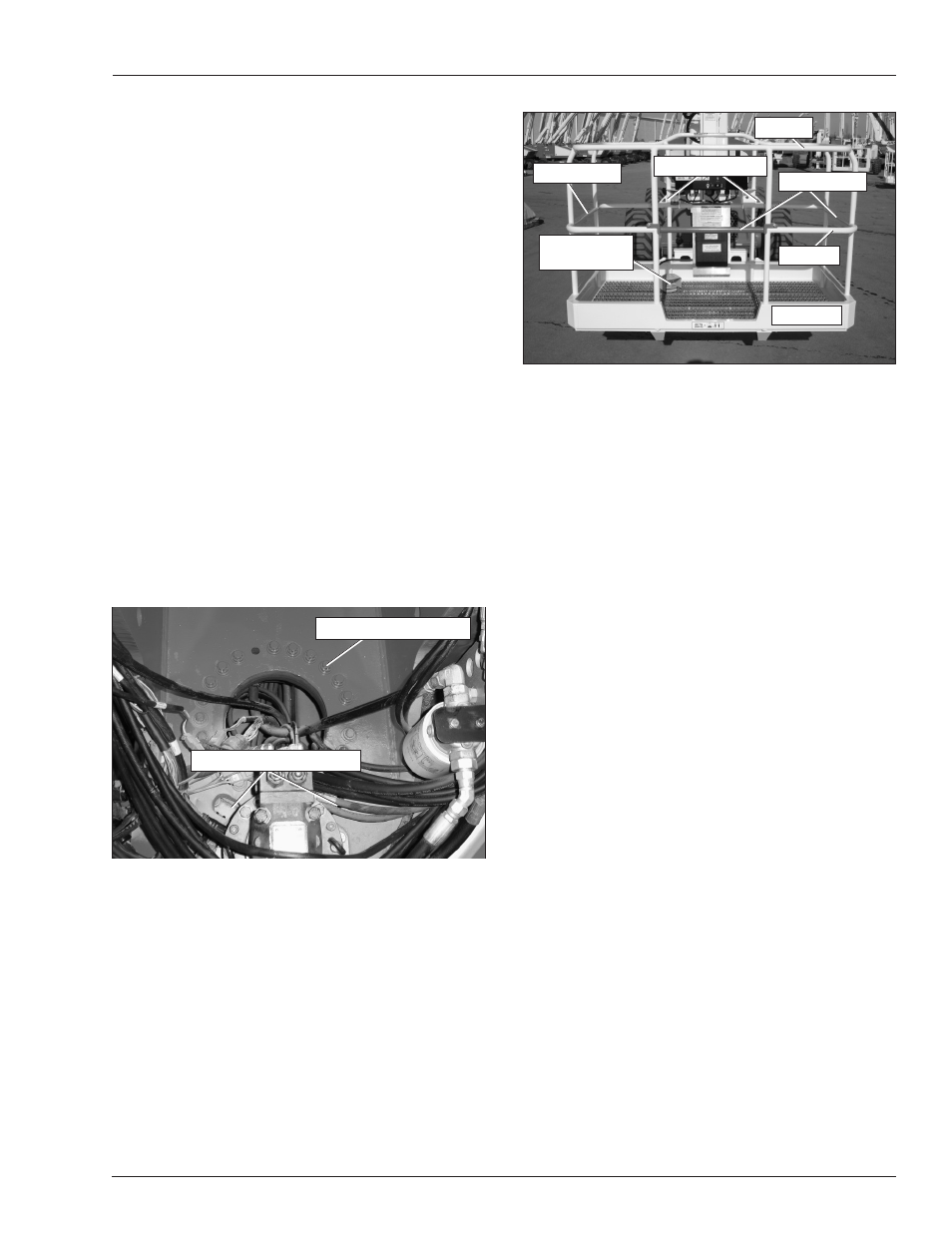

The guardrail system includes (refer to Figure 7.13):

• A top rail

• A mid rail

• Three entry gates: one on each side and one rear

• Toeboards around the sides of the platform.

Figure 7.13 – Guardrail System

To inspect the guardrail system:

1. Visually inspect all components of the guardrail

system. Make sure the rails and toeboards are all in

place and free of any damage or deformation.

2. Visually inspect the rail and toeboard welds for

cracks.

3. Visually inspect all bolts and nuts fastening the plat-

form in place. They must be present and not show

any signs of looseness.

4. Inspect the gravity gates to be sure they are present,

are not damaged, and move freely.

Lanyard Anchors

There are two lanyard anchors below the upper control

panel (refer to Figure 7.13).

To inspect the lanyard anchors:

1. Visually inspect the lanyard anchors to make sure

they are in place and are not deformed.

2. Look for visible cracks in the welds and at the weld

to parent material joints. A bright light may be used

to provide adequate visibility of the inspection area.

Operating Controls

Use the following procedure to operate the machine from

the upper controls:

1. Turn the battery disconnect switch on.

2. At the lower controls, place the emergency stop

switch and the start switch in the on position. Place

the controls switch in the upper control position.

3. At the upper controls (refer to Figure 7.14), pull the

emergency stop button outward.

Rotation Bearing Bolts

Outer Race Access Holes

Toeboard

Platform Foot

Switch

Lanyard Anchors

Top Rail

Mid Rail

Gravity Gate

Gravity Gate