Transportation, By crane, By truck or trailer – Snorkel AB46-sn1000+ANSI User Manual

Page 6: Emergency operation, Lowering elevating assembly, Rotating turret, Emergency towing, After use each day

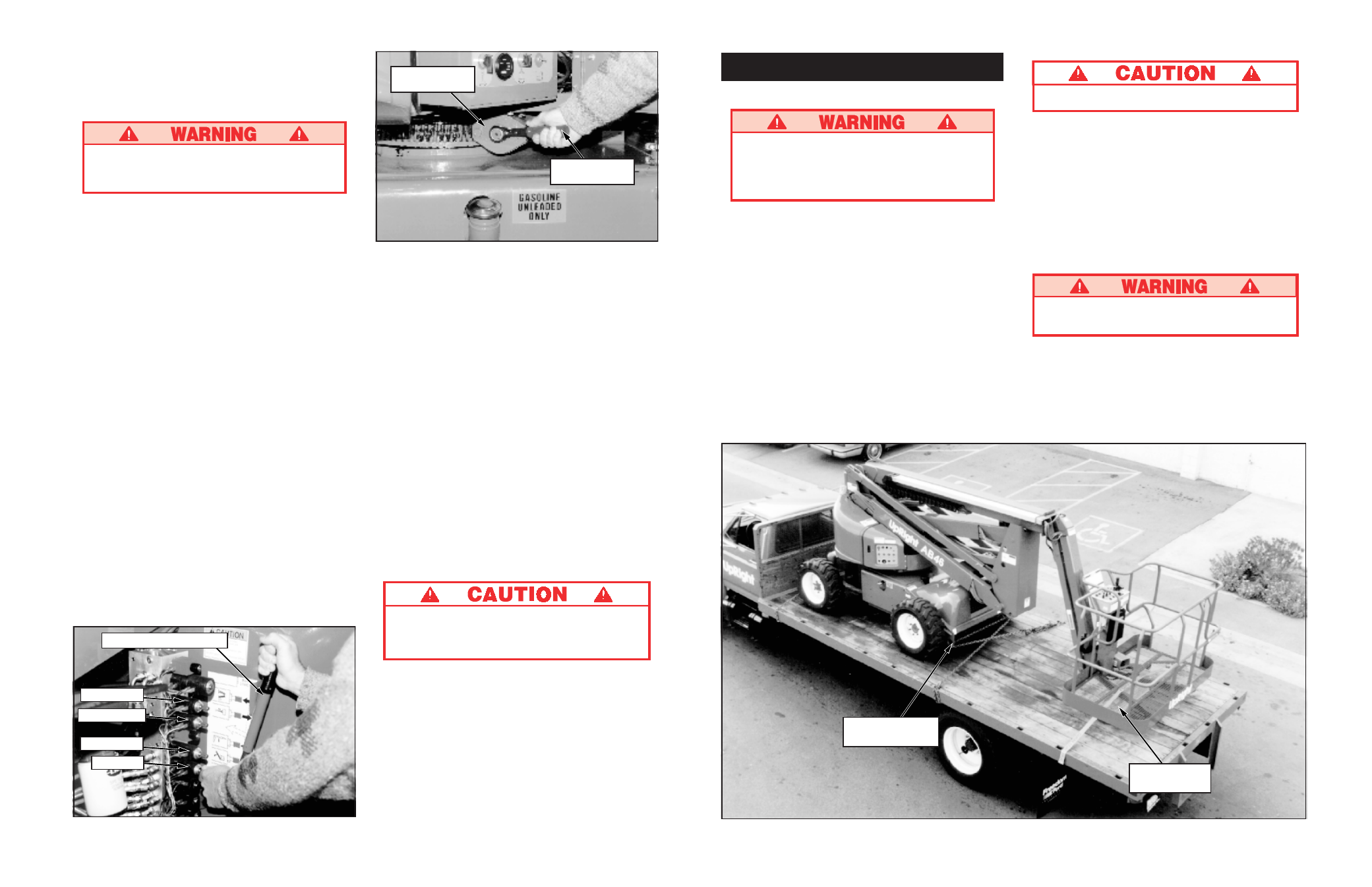

Figure 6: Securing the Machine for Transportation

Transportation

BY CRANE

Stand clear of machine when lifting.

Check specifications on back page, insure

that crane and slings are of correct capacity

to lift weight of unit.

1. Insure that boom is fully lowered and retracted.

2. Attach straps to chassis lifting lugs only. Insure

that straps are adjusted properly to keep unit

level when lifting.

BY TRUCK OR TRAILER

1. Insure that boom is fully lowered and retracted.

2. Maneuver the machine onto bed of truck / trailer.

3. When winching, follow instructions for emer-

gency towing on page 6. Attach winch cable to

front tie down lugs.

Do not winch machine faster than 3 mph.

4. After winching, insure that brakes are set.

5. Secure the machine to the transport vehicle

using chains / straps of adequate load capacity

(refer to specifications, back page) attached to

chassis tie down lugs (see figure 6).

6. Place a wooden block (7.5" x 4" x 28") under

platform support braces as shown (see figure 6).

7. Attach ratchet strap; under platform floor grating,

over support braces (see figure 6). Tighten

securely, do not overtighten.

NEVER elevate the machine while on a truck

or trailer.

Wooden Block

7.5" x 4" x 28"

Chassis Tie Down /

Lifting Lug (typ.)

EMERGENCY OPERATION

In the event of powered function failure, the elevat-

ing assembly may be lowered manually by the

following procedure.

NEVER climb down the elevating assembly.

If controls do not respond, ask someone on

the ground to lower the boom manually.

Lowering Elevating Assembly

1. Open the cover on the hydraulic module (opposite

side of the turret from the chassis control panel).

2. Remove the wire loop retainer from the hand

pump lever, and extend the handle upward to

gain leverage.

3. Operate the manual override (knurled knob) on the

appropriate valve (see fig. 4). Push in to lower /

extend, pull out to raise / retract as required.

4. While holding the appropriate valve in position,

pump the handle in and out until that section of

the elevating assembly is lowered / retracted.

5. Repeat as necessary operating each valve until

the elevating assembly is fully lowered.

Rotating Turret

1. To manually rotate the turret, remove the manual

turret crank from inside of the control side turret

cover.

2. Set ratchet direction on turret crank.

3. Place the socket of the crank onto the hex shaft

stub of the turret rotation gearbox.

4. Turn the crank clockwise to rotate the turret

counterclockwise, turn counterclockwise to rotate

the turret clockwise.

Figure 4: Emergency Control Operation

EMERGENCY TOWING

Perform the following only when the machine will not

operate under its own power and it is necessary to

move the machine or when winching onto a trailer

for transportation.

The batteries must be connected in order to release

the brakes.

1. Insure that the platform is fully lowered, and that

the turret is rotated so that the platform is to the

rear of the machine.

2. Attach chain / cable of sufficient strength for

towing the machine to front or rear tie down lugs.

3. Turn the keyswitch to the parking brake release

position. Alarm will sound.

4. Operate the brake release hand pump located

on the back of the right rear bulkhead.

5. After moving the machine, return the keyswitch

to the off position and remove the key to prevent

unauthorized operation.

DO NOT move the machine faster than 3

mph. Faster speeds will damage drive

components and void warranty.

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

under cover, secure against vandals, children or

unauthorized operation.

3. Turn the key switch to OFF and remove all keys

to prevent unauthorized operation.

Figure 5: Manual Turret Rotation

Emergency control pump

Riser Valve

Boom Valve

Extend Valve

Jib Valve

7

/

8

in. Ratcheting

Wrench

Turret Rotation

Gear Box

6

7