Maintenance, Elevating the upper boom, Extending the upper boom – Snorkel AB46-sn1000+ANSI User Manual

Page 5: Elevating the jib, Rotating the platform, Leveling the platform, Rotating the turret, Elevating the riser, Fueling gasoline, Diesel

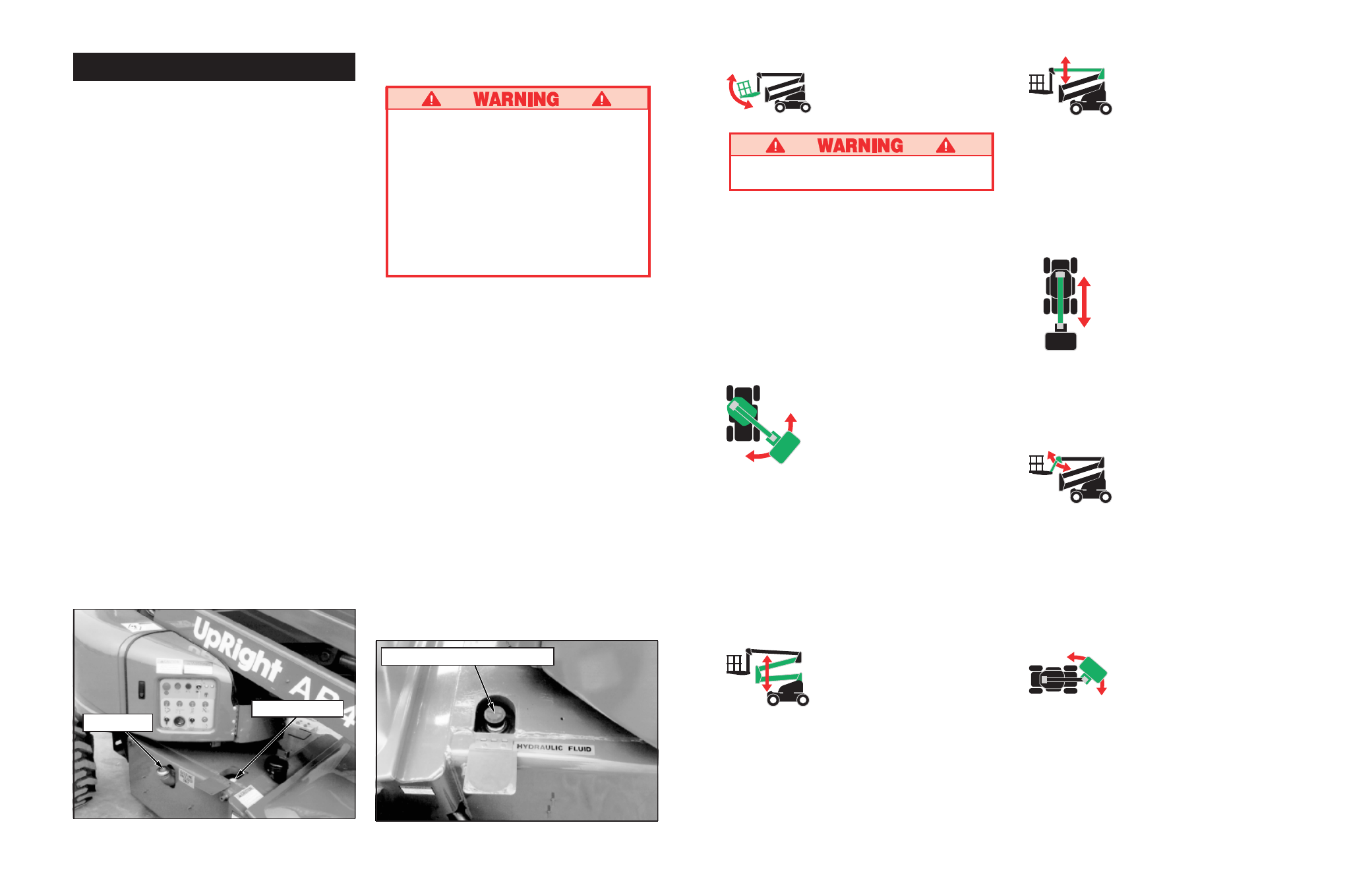

Elevating the Upper Boom

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, push the upper

boom control lever forward to elevate the upper

boom, rearward to lower the upper boom. Release

the control lever to stop elevating / lowering.

Extending the Upper

Boom

1. While depressing the foot switch, push the boom

extension control lever rearward to extend the

boom, forward to retract the boom. Release the

control lever to stop extending / retracting. The

boom extension will function at a constant speed,

function speed control setting is not necessary.

Elevating the Jib

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, push the jib

control lever forward to elevate the jib, rearward

to lower the jib. Release the control lever to stop

elevating / lowering.

Rotating the Platform

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, turn the plat-

form rotation control switch counterclockwise to

Leveling the Platform

DO NOT operate the machine if the plat-

form does not maintain level when elevated.

Note: Platform leveling can be performed only

with the boom stowed and should be done only

to calibrate the automatic leveling system.

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, push the

platform level control switch forward to swing the

platform upward, rearward to swing the platform

downward. Release the switch to stop leveling.

Rotating the Turret

1. Set the function speed control dial to the desired

setting. Rotate the dial clockwise to increase

speed, counterclockwise to decrease. If you are

not sure what speed to use, start out slow; the

speed can be varied while operating the function.

2. While depressing the foot switch, turn the turret

rotation control switch counterclockwise to rotate

left, clockwise to rotate right. Release the switch

to stop rotation. Observe the area around the

boom when rotating the turret to avoid any

obstructions.

Elevating the Riser

1. While depressing the foot switch, push the riser

control lever forward to elevate the riser, rear-

ward to lower the riser. Release the control

lever to stop elevating / lowering. The riser will

function at a constant speed, function speed

control setting is not necessary.

Maintenance

FUELING

Gasoline

1. Open fill pipe cap located on chassis left side

(see figure 7).

2. Fill to capacity with unleaded motor fuel only.

3. Check fuel level by lifting flap located on top of

chassis left side (see figure 7). Fuel tank full

capacity is 25 US gallons.

Diesel

1. Open fill pipe cap located on chassis left side

(see figure 7).

2. Fill to capacity with diesel motor fuel only, grade

#1-D, or #2-D. Use distillate fuel only, do not

use residual or blend..

3. Check fuel level by lifting flap located on top of

chassis left side (see figure 7). Fuel tank full

capacity is 25 US gallons.

HYDRAULIC OIL

1. Check oil level at sight gauge inside engine

compartment right hand side with the platform

fully lowered.

2. If necessary, fill to capacity with clean ISO 46

compatible hydraulic oil.

3. Lift flap located on top of chassis right side (see

figure 7).

4. Open filler / breather cap to add hydraulic oil.

5. Replace cap.

LUBRICATION

Refer to service manual for lubrication chart and

guidelines.

BATTERY MAINTENANCE

Hazard of explosive gas mixture. Keep

sparks, flame and smoking materials away

from batteries.

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Rinse away

any spilled fluid thoroughly with clean water.

Always replace batteries with UpRight

batteries or manufacturer approved replace-

ments weighing 62 lbs. each.

Check battery fluid level daily, especially if work

platform is being used in a warm, dry climate.

If electrolyte level is lower than 3/8 in. (10 mm)

above plates add distilled water only. DO NOT use

tap water it will shorten battery life.

Keep terminals and top of battery clean.

TIRES

Tire selection can affect the stability of the machine.

Use only tires supplied by UpRight unless approved

by the manufacturer in writing.

Figure 7: Fuel Fill Pipe and Level Gauge

Figure 8: Hydraulic Oil Filler / Breather Cap

Fuel Fill Pipe

Hydraulic Oil Filler / Breather Cap

Fuel Level Gauge

8

5