Introduction, Pre-operation and safety inspection, System function inspection – Snorkel AB46-sn1000+ANSI User Manual

Page 2

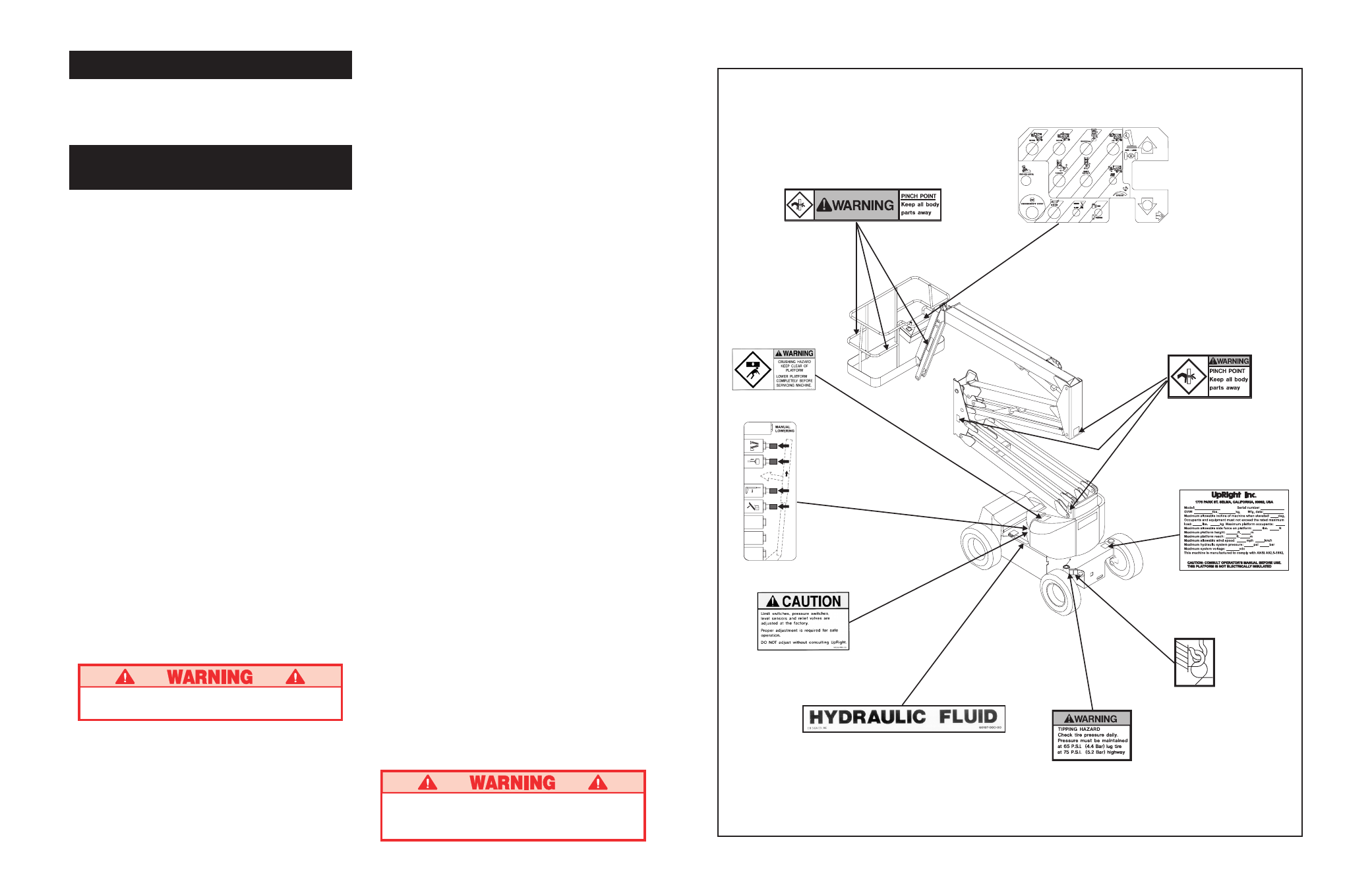

Figure 9: Label Identification (cont.)

068634-000

1 REQUIRED

(INSIDE)

AB - 46 Label Installation: All of the labels shown in figure 9 shall be present and

in good condition before operating the work platform. Be sure to read,

understand and follow these labels when operating the work platform.

066553-001

3 REQUIRED

068586-000

1 REQUIRED

066568-000

2 REQUIRED

066553-004

5 REQUIRED

066555-000

2 REQUIRED

(INSIDE)

061205-002

1 REQUIRED

068635-000

4 REQUIRED

062562-001

4 REQUIRED

060197-000

1 REQUIRED

Introduction

This manual covers the operation of internal com-

bustion powered models of the AB-46 Articulated

Boom. This manual must be stored on the machine

at all times.

Pre-Operation and Safety

Inspection

Carefully read, understand and follow all safety

rules, labels, and operating instructions, then

perform the following steps each day before use.

Perform a complete visual inspection of the entire

unit prior to operating. Check the following areas for

discrepancies:

1. Open panels and check hydraulic components /

hoses for damage or leaks. Check electrical compo-

nents / wiring for damage or loose connections.

2. Inspect chassis, axles, hubs, and steering

linkage for damage, deformation, buckled paint,

loose or missing hardware, and cracked welds.

3. Check tires for damage, punctures, and inflation;

tire pressure must be 65 psi.

4. Check all hoses / cables for wear.

5. Inspect elevating assembly for damage, defor-

mation, buckled paint, loose or missing

hardware, and cracked welds.

6. Inspect platform and guardrails for damage,

deformation, buckled paint, loose or missing

hardware, and cracked welds. Insure that gate

operates freely and latches securely.

7. Check Hydraulic fluid level with platform fully

lowered.

8. Check battery fluid level (see battery mainte-

nance, page 8).

9. Check fuel level, add fuel if necessary (see

fueling, page 8).

10.Ensure that radiator is cold, check coolant level.

Add if necessary.

NEVER remove the cap from a hot radiator.

Hot coolant can cause severe burns.

SYSTEM FUNCTION INSPECTION

Note: Refer to figures 1 and 2 for chassis and

platform control locations.

1. Before performing the following tests, check area

around machine and overhead for obstructions,

holes, drop-offs, and debris.

2. Turn chassis key switch to chassis, and turn on

(rotate clockwise) emergency stop switches at

the chassis control panel and at the platform

control panel.

3. Press the engine start button to crank the en-

gine; release when engine starts. If engine is

cold: press and hold the choke button while

starting gasoline / propane models; press the

glow plug button and hold for six seconds prior to

starting diesel models.

4. Push in the chassis emergency stop button

engine should stop. Repeat for platform emer-

gency stop button. Return both emergency stop

buttons to the on position, and start engine.

5. Operate each function switch to raise / lower,

extend / retract, rotate left / right, each section of

the elevating assembly and observe the opera-

tion of the machine. All functions should operate

through full cycle smoothly.

6. Turn chassis key switch to platform.

7. Mount the platform, close and latch the gate, and

attach approved fall restraint to designated platform

anchorage point. Attach only one fall restraint to

each point.

8. Start the engine.

9. Without depressing the foot switch, move the

drive control handle, machine should not function.

10.Depress the foot switch and move the drive

control handle forward and reverse. Observe

that proportional functions operate smoothly, and

that brakes apply quickly after control is re-

leased.

11.While depressing foot switch, operate steer

switch to left and right. Observe that steering

wheels turn properly.

12.While depressing foot switch, turn function speed

control knob to desired setting, and operate

boom controls. Observe that boom operates

smoothly, and that upper boom, jib, turret rota-

tion, platform level, and platform rotation controls

operate proportionally in conjunction with func-

tion speed control knob. Observe that platform

maintains level when boom is elevated.

13.With the upper boom elevated one foot, operate

drive control handle. Observe that drive speed is

limited to creep (1/2 foot [.15m] per second).

Lower upper boom to stowed position.

14.Press the service horn button. Observe that

horn is audible.

DO NOT use a machine that is damaged or

malfunctioning. Tag and remove the unit

from service until it is repaired.

11

2