Micropump GM Series Service Instructions User Manual

Page 6

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Howard Road, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 8ET England, • Phone: (44) (0) 1480-356600• Fax: (44) (0) 1480-35630

0

REVISION

LTR.

DESCRIPTION

DATE

BY

A

ORIGINATED PER E14164

1/28/04

CMA

PART NUMBER:

L23154

Page 6 of 9

6.5 Bushing Installation

6.5.1 Remove all bushings (3) from bearing plate (2) and pump body (10) using

a tap and handle. Thread tap into bushing approximately ½” (12 mm) and pull

bushings out.

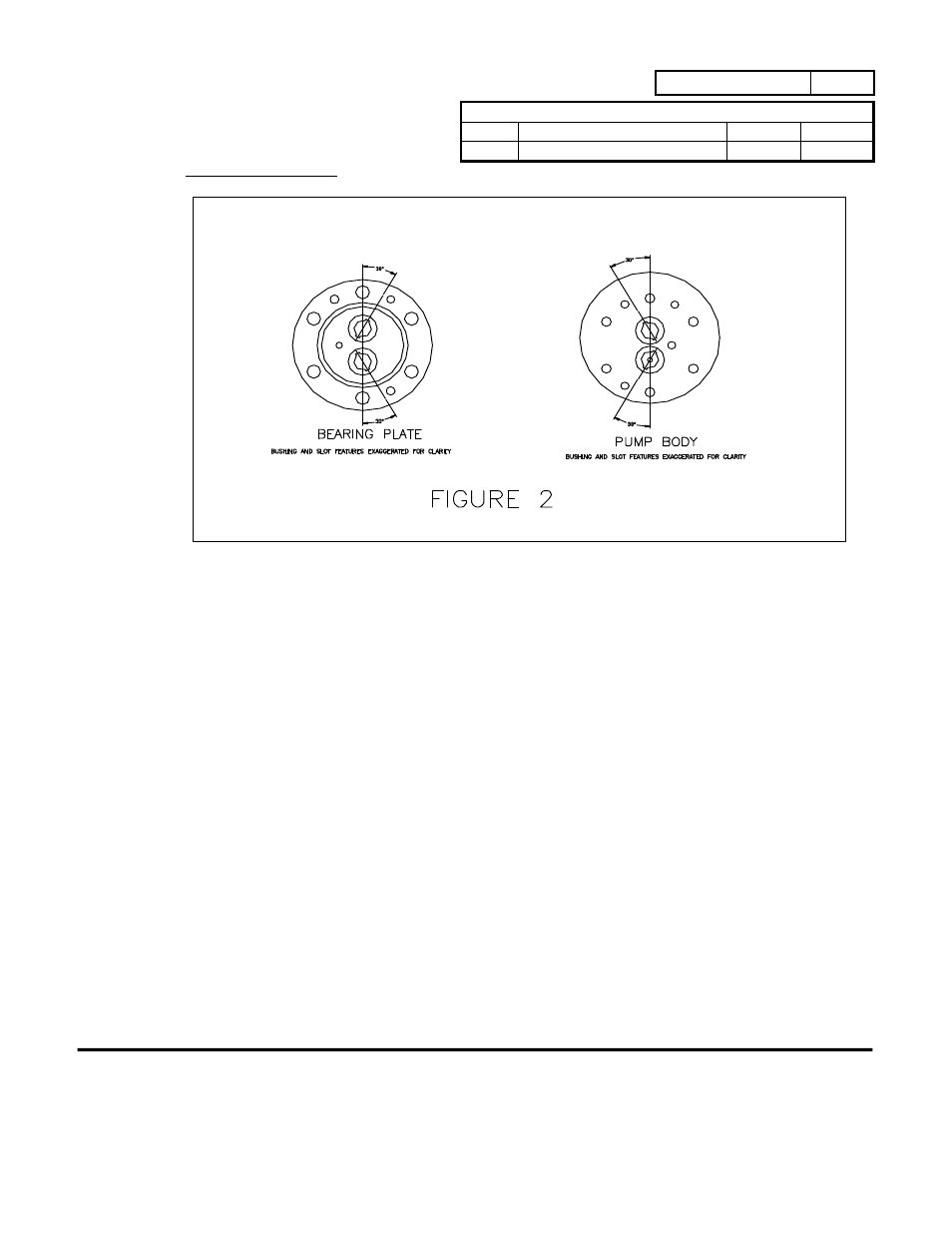

6.5.2 Install 4 bushings into bearing plate (2) 0.010” to 0.020” (0.26 mm to 0.51

below bearing plate sealing surface, with the slots (if present) aligned as shown in

figure 2. Use a bushing insertion tool and hand press or non-rotating drill press.

6.5.3 Install the first 4 bushings into pump body (10) 0.010” to 0.020” (0.26 mm

to 0.51 mm) below sealing surface of the “gear end” of the pump body. Align the

bushings slots as in figure 2. Install the remaining bushing into pump body from

driven magnet (12) end, aligning the slots as in figure 2, and the bushing flush with

the pump body surface.

6.5.4 Check all bushings for proper installation depth. Check bushings after

installation with a new gear shaft to insure that clearance between shafts

and bushings is at least a sliding fit.

6.5.5 If bushings are tight on shafts, very carefully hand ream bushings after

installation using a 0.251” (6.4 mm) diameter reamer. This should be

done as straight as possible to obtain maximum perpendicularity. Do not

force reamer into bushings, and do not ream bushings unless necessary.