Micropump GM Series Service Instructions User Manual

Page 2

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Howard Road, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 8ET England, • Phone: (44) (0) 1480-356600• Fax: (44) (0) 1480-35630

0

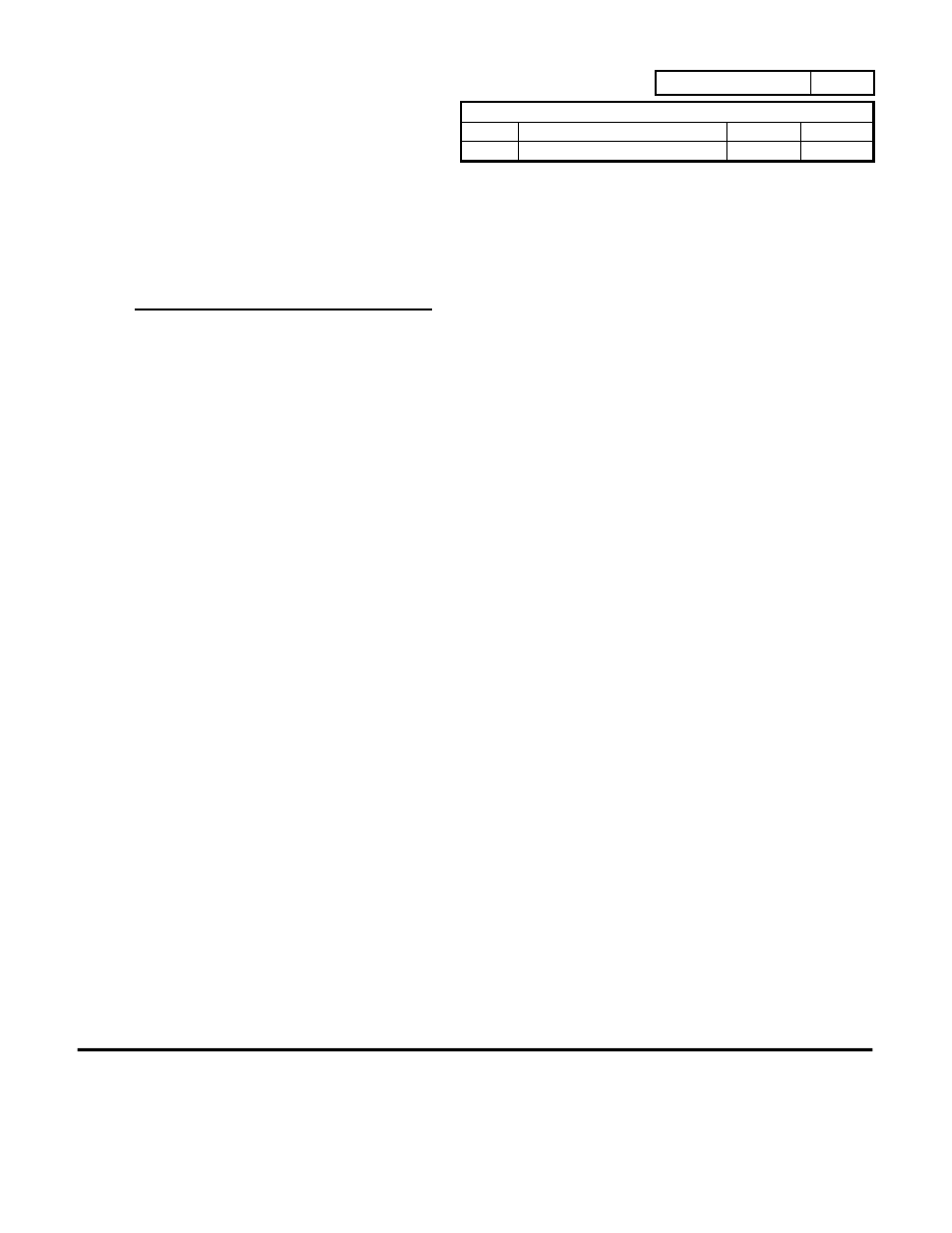

REVISION

LTR.

DESCRIPTION

DATE

BY

A

ORIGINATED PER E14164

1/28/04

CMA

PART NUMBER:

L23154

Page 2 of 9

2.4

Surface plate or equivalent flat

surface

2.5

Bushing insertion tool (or arbor press)

2.6

Reamer for bushings

2.7

Silicone vacuum Grease

2.8

Stoddard Solvent or liquid detergent

3.

Disassembly of Pump (Refer to Figure 1)

Note: Prepare a clean, flat area, free of metal particles.

3.1

Place pumphead on surface with housing facing up.

NOTE: EXERCISE CAUTION IN THE FOLLOWING STEP.

ENTRAPPED FLUID WILL BE RELEASED WHEN PUMP BODY

AND MAGNET CUP ARE SEPARATED.

3.2

Remove the screws (15), qty 16 (Qty 8 for low pressure version), and pull the drive housing (14) and

magnet cup (13) from the pump body (10).

3.3

Separate magnet cup (13) and drive housing (14).

3.4

Loosen the setscrew on the driven magnet (12) and remove magnet from

driving gear (6) shaft.

Note: Store the driven magnet (12) in a clean bag and keep away

from other magnets and sensitive electronic equipment.

3.5

Remove screws (1), qty 6, and pull bearing plate (2), cavity plate (8), and

two of the dowel pins (5) straight away from pump body (10).

3.6

Separate bearing plate (2), cavity plate (8), and two dowel pins (5) from each other. Gently

lift the wear plates (4) (if used), qty 4, out of the cavity plate (8), taking care to pull them

straight out.

Note: If dowel pins are difficult to remove, protect pins with a soft

material (i.e. plastic or rubber) and remove them with pliers.

Replace pins if damaged.

3.7

Remove driving gear (6) and driven gear (7) from pump body (10).

3.8

See repair instructions, section 6.5.1 regarding bushing (3), qty 9, removal.