Troubleshooting 10 – Lukas CT7 User Manual

Page 22

22

Troubleshooting

10.

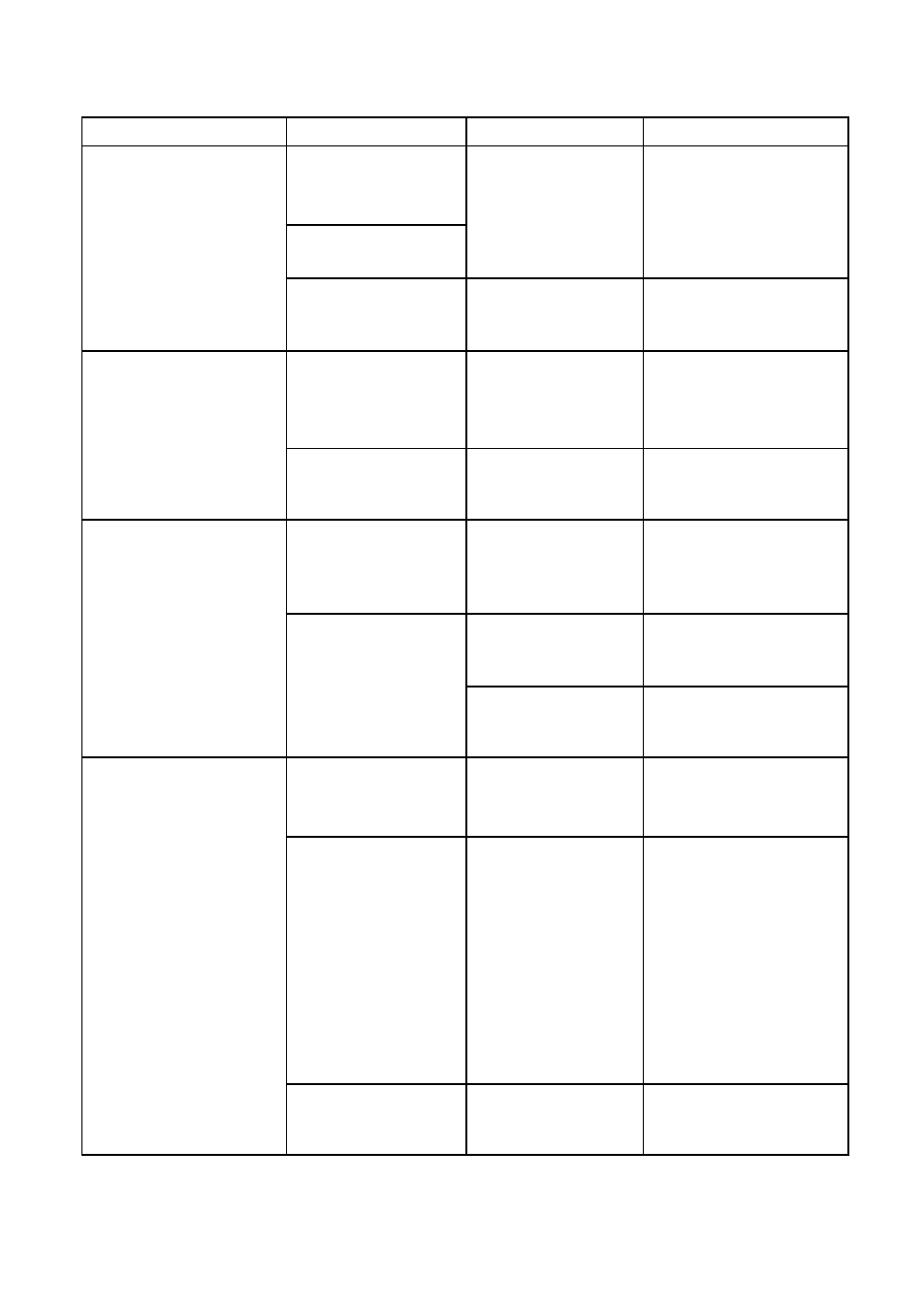

Trouble

Check

Cause

Solution

Connected

implements move

slowly or jerk in

response to control

command

Hose lines

connected

correctly?

Air in the hydraulic

system

Vent the hydraulic

system

Pump assembly

running?

Defective

implement.

Consult the operating

instructions for the

implement.

Connected

implements do not

move in response to

control command and

no pressure reading

on the control desk

pressure gauge.

Hose lines

connected

correctly?

Hose line to

hydraulic unit

not connected

correctly.

Connect the hose

lines correctly.

Pump assembly

running?

Pump assembly

not switched on or

defective.

Consult the operating

instructions for the

pump assembly.

Connected

implements do not

move in response to

control command but

a pressure reading is

shown on the control

desk pressure gauge.

Switch position

of the manual

pressure shut-off

valve

Manual pressure

shut-off valve in

“closed position”

Switch the manual

pressure shut-off

valve to the “working

position”.

Defective control

desk

Have repaired by

authorised dealer or

directly by LUKAS.

Problem with the

implement.

Consult the operating

instructions for the

implement.

Connected implement

does not produce its

rated force.

Hydraulic fluid

level in the supply

pump?

Insufficient

hydraulic fluid in

the pump

Top up the hydraulic

fluid and bleed

Check the

operating pressure

on the control desk

pressure gauge

Insufficient supply

pressure

If possible, increase

the max. operating

pressure at the

hydraulic unit to

the max. operating

pressure of the

cylinder or use a

different hydraulic

unit with sufficient

max. operating

pressure.

Check the

implements

Defective

implements

Consult the operating

instructions for the

implements.