2) initial bench check, 3) installing the instrument – J.P. Instruments Slim Line Gauges Installation Guide User Manual

Page 2

INSTALLING THE SLIM LINE® INSTRUMENT SERIES

PAGE 2 OF 14

REV

B

J. P. INSTRUMENTS

PO Box 7033

Huntington Beach, CA 92615

2) Initial Bench Check

Connect the red wire to +12V or +24 V and the black wire to power return. Verify that the display lights up. If

the alarm limit has to be changed, it will be easier to do it now before the instrument is installed in the aircraft.

See the procedures near the end of this manual.

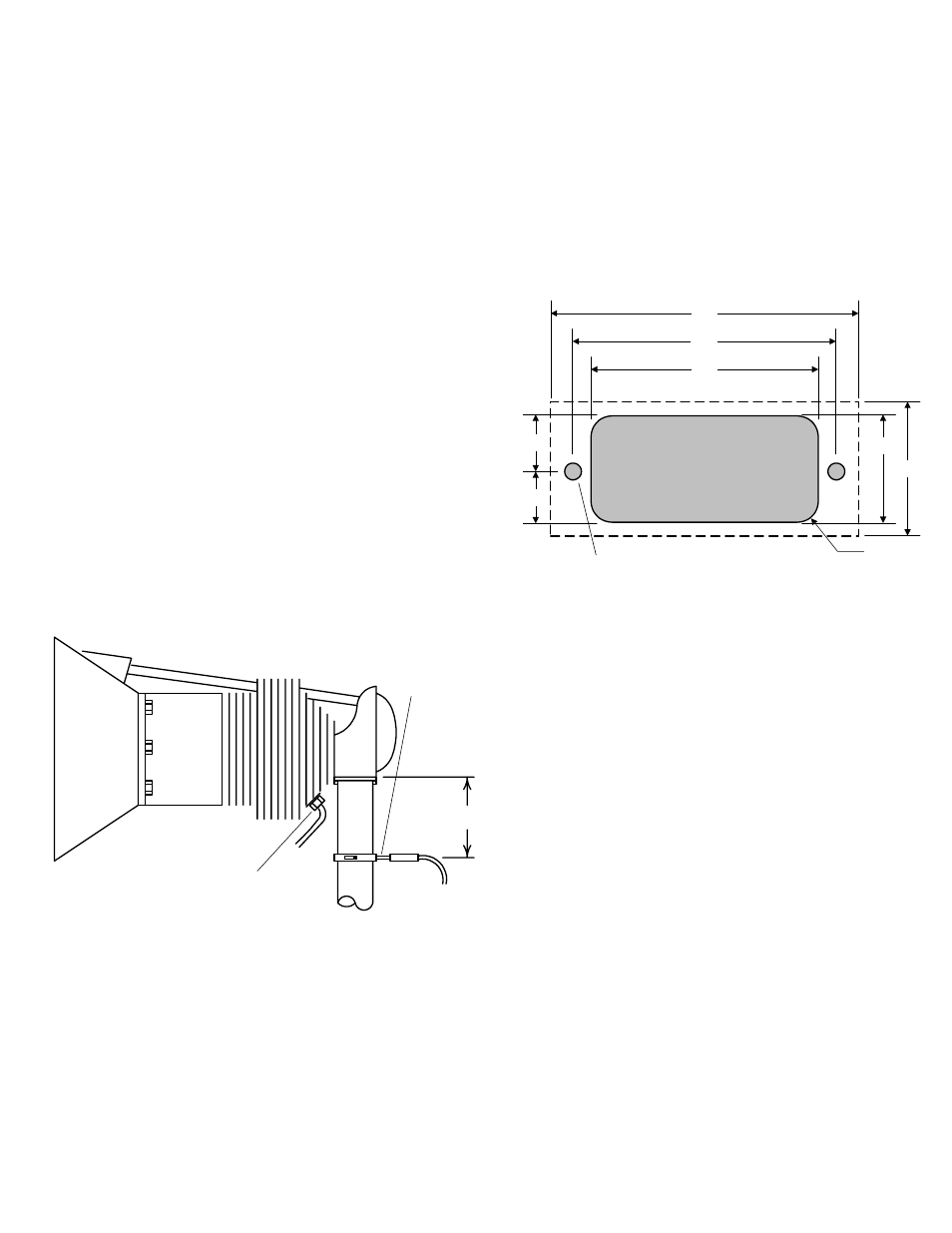

3) Installing the Instrument

Installation should be in accordance with Advisory Circular

AC43.13-1A. Identify the location for the instrument on the

instrument panel that can accommodate 2.75 inches wide by

1.2 inch high instrument, and 3.5 inches clearance behind

the instrument panel. Check the rear clearance with the

connectors attached to the instrument.

If more than one instrument is to be installed, the horizontal

center-to-center spacing must be at least 2.75 inches, and

the vertical center-to-center spacing must be at least 1.2

inches. Two instruments can be installed in a 3¼ inch hole.

Contact JPI for an optional bezel.

4) Exhaust Gas Temperature (EGT) Probe

Installation

Determine the locations of all holes before

drilling to ensure that nothing interferes with the

probe, clamp, clamp screw or wire. The model

M-111 EGT probe will fit any engine having

existing holes in the exhaust stack of between

0.125 in. and 0.250 in. If no hole exists, drill a

0.125 in. hole and ream to fit. For multi-EGT

probe installations, it is important that each probe

be mounted a uniform distance from the exhaust

stack flange. A nominal distance of 2 to 4 inches

from the exhaust flange is recommended. If the

recommended distance is impractical due to

obstructions, slip joints or bends in the exhaust

system, then position the probes a uniform

distance from the flange as space permits. Careful matching of probe position will provide the best temperature

readings. Do not mount EGT probes in slip joints.

Insert the probe in the exhaust stack hole such that the tip of the probe is in the center of the exhaust stream.

Tighten the stainless steel clamp and torque to 45 in/Lbs. Cut off excess strap close to the screw.

5) Turbine Inlet Temperature (TIT) Probe Installation

The standard TIT probe PN M111-T with a #48 clamp is placed in the exhaust stack accumulator to a maximum

depth of 1/2 inch and approximately 4 inches from the turbine inlet if possible, on the wastegate side of the

turbine.

2" to 4"

EGT probe

Drill no. 40

pilot hole,

then no. 30

hole.

CHT probe

exhaust stack

instrument panel cutout

2.35

2.03

0.46

R0.125

0.169 D 2 plcs

2.75

1.20

0.51

0.97 ref