Maintenance – GFB DV+ TMS Diverter Valve (part T9301) User Manual

Page 4

Maintenance

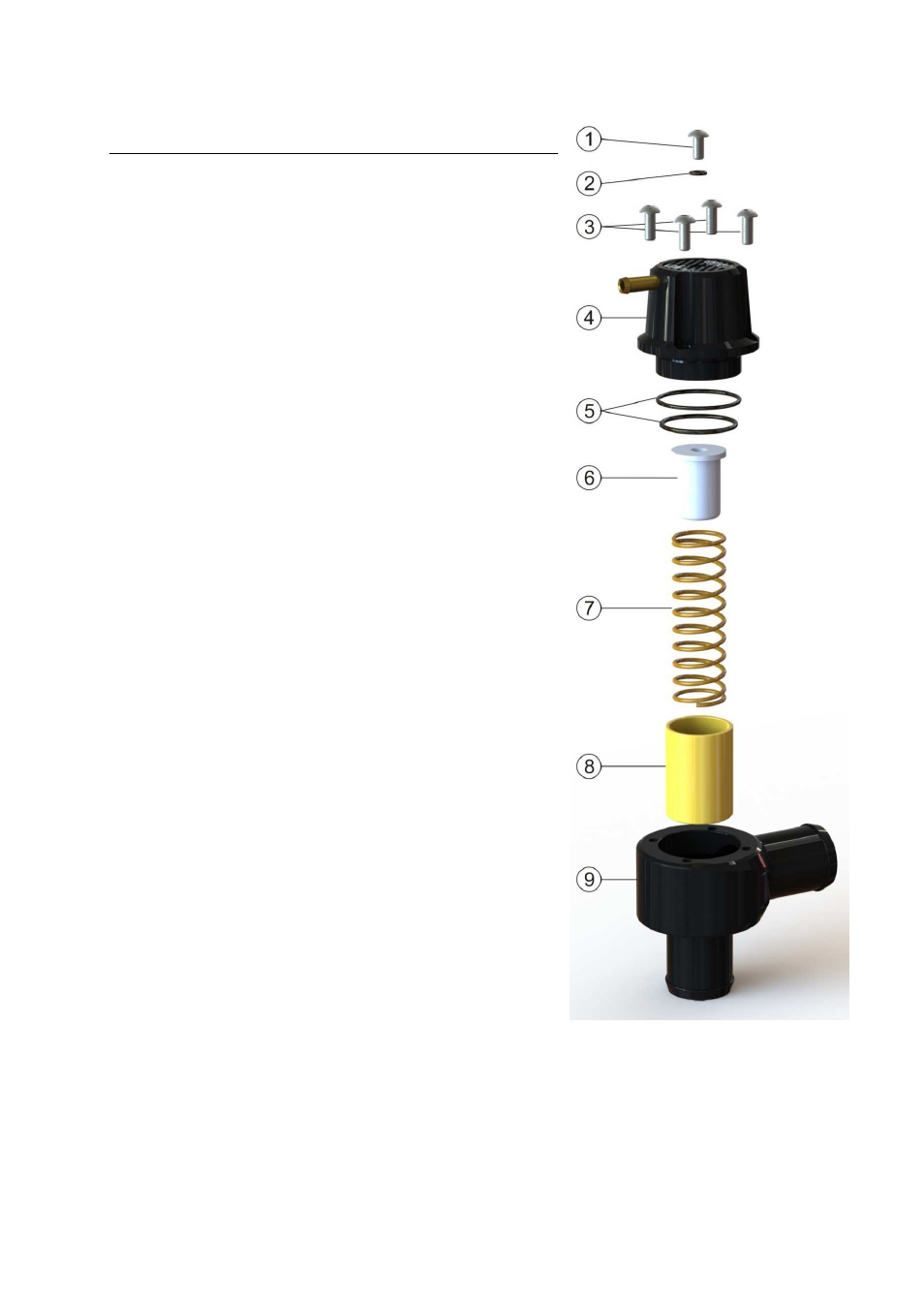

Disassembly:

•

Using a 2.5mm hex key, remove the 4 cap screws (3) whilst

holding the cap (4) to prevent it from popping off – the

spring force is relatively small, but if it pops off

unexpectedly, the internal parts can be easily lost. Note

that the friction from the o-ring (5) may hold the cap on

even after the screws are removed. If this is the case,

simply twist the cap and pull at the same to remove it.

•

Remove the spring cap (6), spring (7) and piston (8) from

the body (9). The o-rings (5) will remain attached to the

cap.

Reassembly:

•

Fit the spring cap (6), spring (7) and piston (8) into the cap

(4), then slide the cap into the body (9).

•

Twist the cap so the vacuum nipple points in the desired

direction, then re-install the cap screws (3).

Lubrication:

There is no set specific re-lube interval, as the dv+ does not rely

on lubrication in order to function correctly. Whereas other

brands use the internal o-rings to actually guide and support

the piston, the dv+ instead uses precision tolerances between

the piston and bore for support and the majority of sealing

duties, and the internal o-ring simply acts as a final “wiping”

seal.

This arrangement means the o-ring lasts much longer (almost

indefinitely) instead of requiring frequent “re-building”, does

not rely on a set lubrication schedule to work properly, and

friction is kept to a minimum for optimum performance.

Oil vapour passing through with the vented air in most cases is

sufficient to keep the valve lubricated, but the amount of oil vapour varies from car to car and

sometimes it is necessary to clean and lube the internals. Typically, if the venting sound changes

over time, this is typically an indication that there may be a build-up of carbon that needs to be

cleaned out.

When disassembled, wipe everything clean with a rag, then apply light grease or engine oil to the

piston, inside the bore, and on the o-rings (5), then reassemble.