Spring adjustment – GFB Respons TMS Valve (part T9033) User Manual

Page 3

Spring Adjustment

Contrary to popular belief, the spring pre-load DOES NOT need to be adjusted to suit different

boost levels. The valve will stay shut under full throttle conditions regardless of boost pressure or

spring pre-load.

Rather, the spring pre-load affects how easily the valve opens

when you lift the throttle, and how long it stays open when it

vents. Adjusting the spring is a simple matter of ensuring the

valve opens enough to release the air, but not long enough to

cause idling problems. The guide below will walk you

through the steps involved.

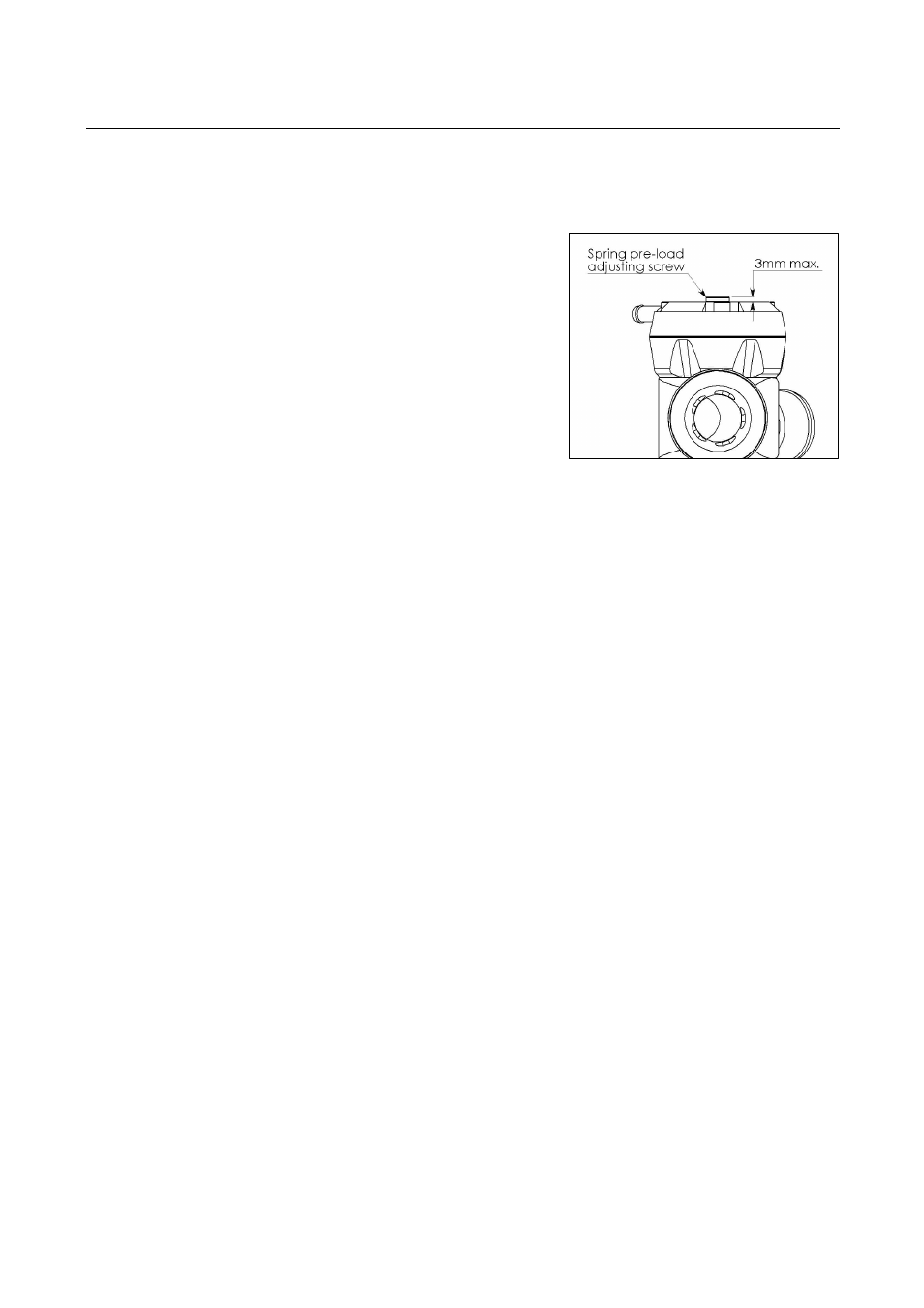

The screw in the centre of the head is the spring adjuster

(shown opposite). Use the supplied 5mm hex key for this

screw.

The softest spring setting is achieved when the top of the adjustment screw is 3mm above the head

of the valve. Do not set the screw more than 3mm above the head.

•

Set the spring to the softest setting, and move the noise adjusting ring to at least 50%

atmosphere venting so you can see the piston through the trumpet

•

Start the car and let it warm up to normal operating temperature. Make sure the A/C is off

•

Give the engine a good hard rev, and watch the piston - WARNING: Keep your face away

from the trumpet opening when revving the engine. View the piston from an angle away

from the blast of air. The piston should lift and vent with a “whoosh”, then close slowly and

smoothly. The harder you stab the throttle, the further the piston will open (note: it will only

open fully when driving, as the turbo does not generate boost until the engine is under load).

•

If the piston stays open too long, and does not close before the revs drop back to idle, the

engine will “stumble”. If this happens, wind the adjustment screw in the “+” direction one

turn at a time until the engine returns smoothly to idle after revving

•

For the final fine-tune, take the car for a drive. Watch the tacho as you pull up to a stop - if

the revs dip below idle and then rise again, tighten the spring another 1-2 turns

•

If a loud flutter is heard when lifting off sharply after accelerating hard above 3500RPM,

wind the adjustment screw in the “-“ direction one turn at a time until the noise disappears.

Note that it is not uncommon to hear a slight fluttering at low RPM, particularly if you

partially spool the turbo and lift off slowly. This is a result of the different way in which this

valve operates compared to the factory unit, and is perfectly normal and not detrimental to

the turbo

A video example of setting up the spring pre-load can be seen at:

http://www.youtube.com/watch?v=iqQR5WUF9lc