Adjusting the noise – GFB Respons TMS Valve (part T9002) User Manual

Page 3

•

Set the spring to the softest setting, and move the noise adjusting ring to at least 50%

atmosphere venting so you can see the piston through the trumpet

•

Start the car and let it warm up to normal operating temperature. Make sure the A/C is off

•

Give the engine a good hard rev, and watch the piston - WARNING: Keep your face away

from the trumpet opening when revving the engine. View the piston from an angle away

from the blast of air. The piston should lift and vent with a “whoosh”, then close slowly and

smoothly. The harder you stab the throttle, the further the piston will open (note: it will only

open fully when driving, as the turbo does not generate boost until the engine is under load).

•

If the piston stays open too long, and does not close before the revs drop back to idle, the

engine will “stumble”. If this happens, wind the adjustment screw in the “+” direction one

turn at a time until the engine returns smoothly to idle after revving

•

For the final fine-tune, take the car for a drive. Watch the tacho as you pull up to a stop - if

the revs dip below idle and then rise again, tighten the spring another 1-2 turns

•

If a loud flutter is heard when lifting off sharply after accelerating hard above 3500RPM,

wind the adjustment screw in the “-“ direction one turn at a time until the noise disappears.

Note that it is not uncommon to hear a slight fluttering at low RPM, particularly if you

partially spool the turbo and lift off slowly. This is a result of the different way in which this

valve operates compared to the factory unit, and is perfectly normal and not detrimental to

the turbo

A video example of setting up the spring pre-load can be seen at:

http://www.youtube.com/watch?v=iqQR5WUF9lc

Adjusting the Noise

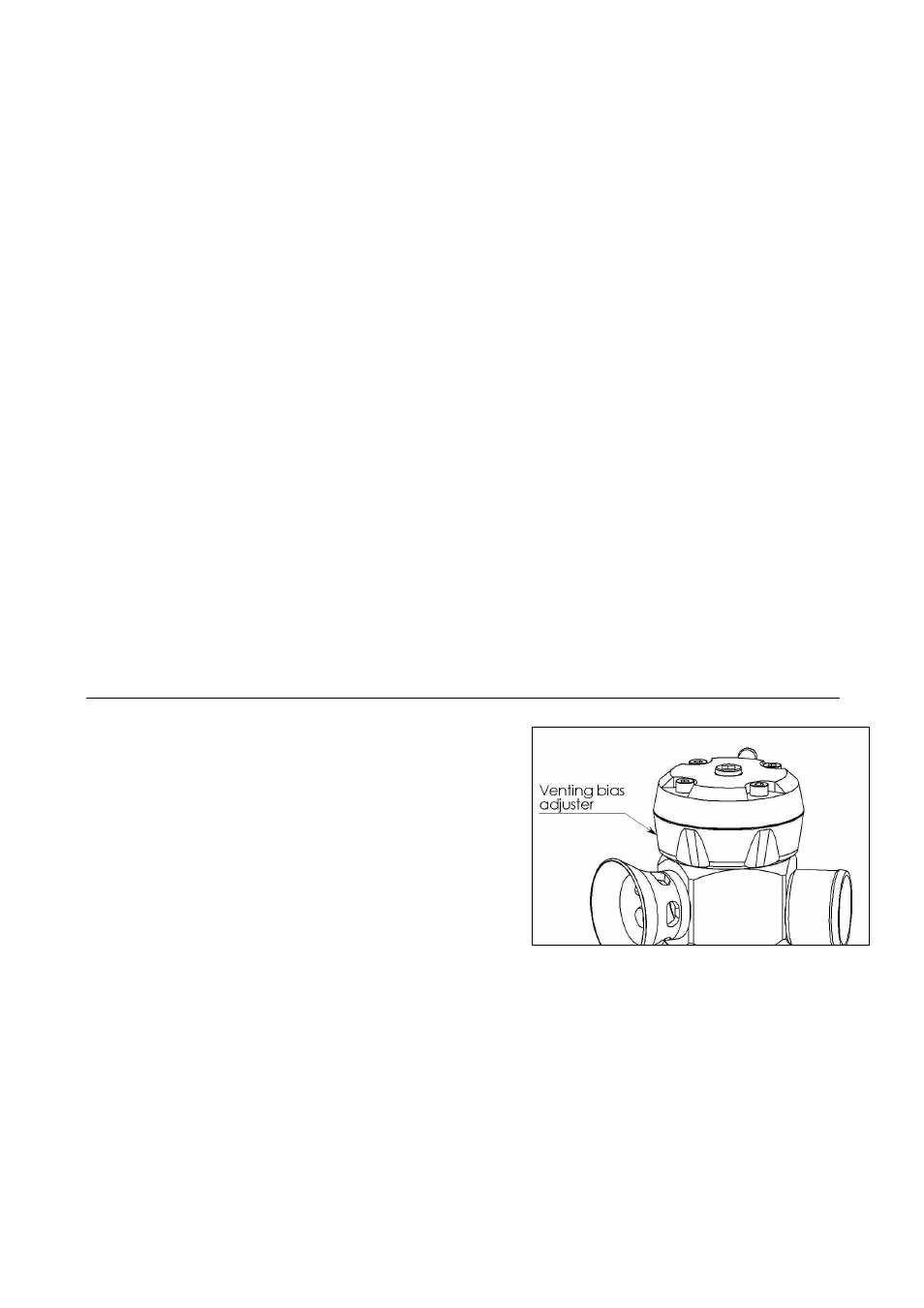

The unique patented venting bias adjustment feature on

the GFB Respons lets you vary the amount of air vented

to atmosphere or recirc, thereby changing the volume of

the sound.

Turning the venting bias adjuster (figure 3) fully anti-

clockwise means all the air will vent through the trumpet,

which is the loudest setting.

Turning the adjuster clockwise from this position will

begin to open up more of the recirc outlet, until a ratio of

50/50 is reached. As you turn the adjuster further clockwise, the recirc port is fully open and the

trumpet port will begin to close. When the adjuster reaches the maximum clockwise position, the

trumpet is completely closed, and the valve will operate like a factory recirculating bypass valve.

Typically, most engines will allow 100% atmosphere venting with no problems, provided the spring

pre-load is adjusted correctly. However, some combinations of modifications can result in

backfiring when the valve vents to atmosphere, in which case the solution is simply to dial back the

amount of air vented to atmosphere until the problem is resolved – this is one of the key benefits of

the venting bias adjustment feature.

Do not be afraid to experiment with the spring and noise settings, no harm will come to the engine

if wrong setting is used.