GFB Short Shift Kit for STi 6 speed transmission (part 4002) User Manual

Page 4

16.

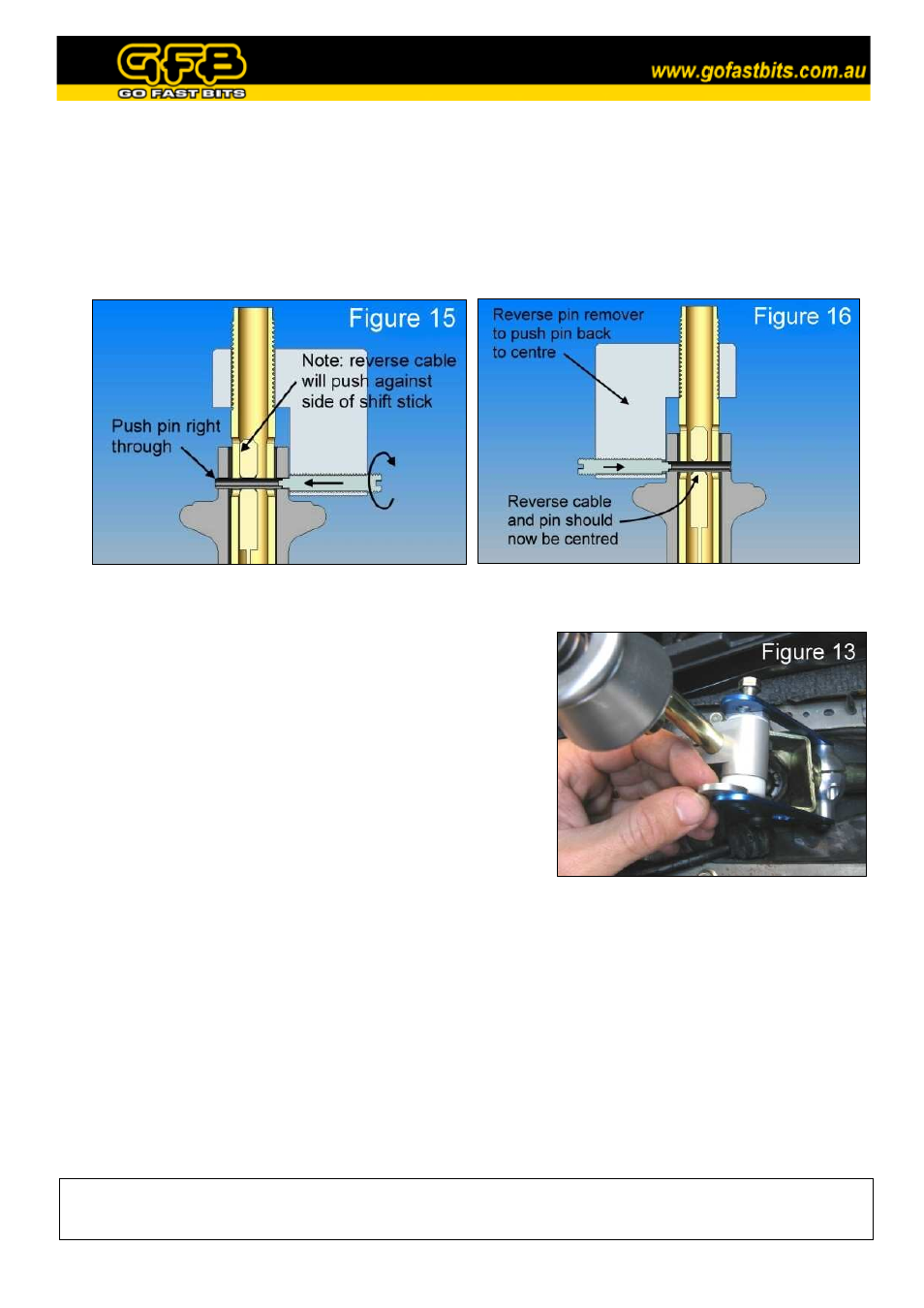

Put the pin remover back onto the gearstick, and drop the roll pin into the threaded hole, followed by the

shorter of the two M5 slot screws. Make sure the end of the roll pin is lined up with the end of the long

M5 slot screw, then begin screwing it into the gearstick (fig. 15). If aligned correctly, the roll pin will

push the longer M5 slot screw out of the gearstick as it is pushed in. Continue until the pin is pushed

about 1mm BEYOND centre. Now unwind the short M5 slot screw, spin the roll pin remover 180

degrees and push the pin back the other way until it is centred (fig. 16). This will ensure the end of the

cable is held in the middle of the gearstick, instead of rubbing against the side (look down the hole in the

top of the gearstick, you will be able to see the position of the cable).

17.

Check the operation of the reverse lever, then fasten the reverse cable with the supplied zip tie.

18.

At this point you will need to decide how short you want the

shift throw to be. This is determined by the height of the

clamp on the gearstick relative to the pivot ball – the higher

the clamp, the shorter the throw (Note: the shorter you make

the throw, the more force will be required to shift, this is

normal). The 3 holes in the blue plates simply ensure that

the gearbox linkage remains at the correct angle (so it

doesn’t foul on the transmission tunnel) regardless of the

clamp position. We suggest beginning with the middle hole.

Make sure the factory steel sleeve is inserted into the white

bushings of the gearstick clamp, then line up the sleeve with

the middle hole. Hold one of the M8 washers between the sleeve and the side plate, then slide the

factory bolt through the side plate, the washer, and into the sleeve. Note that you may have to adjust the

height of the clamp on the gearstick to get the bolt through the holes. Position the second washer on the

other side (fig 13), and push the bolt fully through. Partially thread the nut onto the end of the bolt,

tighten the screw in the gearstick clamp and test the shift feel. If the throw is too short or long, make an

adjustment to the height of the clamp, and if necessary, select a different hole on the side plates so that

the gearbox linkage does not rub or foul in any gear.

Note that as you slide the clamp up and down, the neutral position of the gearstick will move slightly.

By using the combination of the clamp height and hole position, you can tailor the shift feel to your

liking. Once you are satisfied tighten the clamp screw and linkage bolt, then perform a final check to

ensure that you can select all gears (including reverse) smoothly, and without any binding. Replace the

plastic shrouds in the reverse order of removal.

GFB Short Shift Kits carry a lifetime warranty which covers faulty components or manufacturing. Warranty is limited only to the

repair or replacement of GFB products provided they are used as intended and in accordance with all appropriate warnings and

limitations. No other warranty is expressed or implied.