Fitting procedure bull bar preparation – ARB 3915030 User Manual

Page 13

Last Rev Date: 29/10/2008

Page 13 of 24

Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE BULL BAR PREPARATION

40.

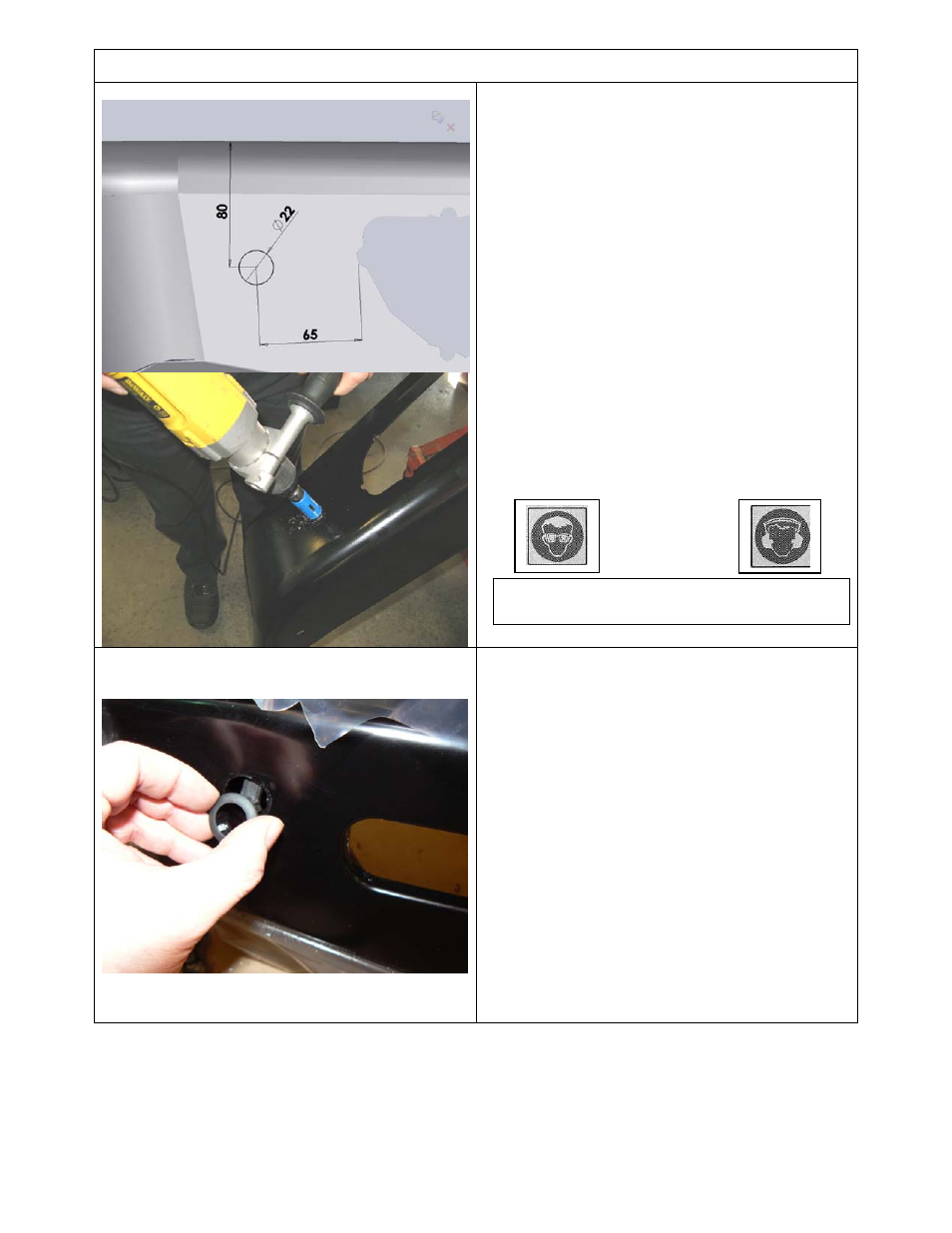

If sensors are to be refitted, position the

bar face up and mark out the hole position

as shown on both wings. Dimensioned

80mm from the top of the wing and 65mm

from the most outboard edge of the light

aperture. This position is optimal for

sensor operation.

41.

Carefully drill the hole with Dia 22.0mm

(7/8”) hole saw.

CAUTION: Do not make the hole smaller

than shown, Dia 22.0 – 22.3 is ideal.

42.

Deburr any sharp edges.

43.

Test fit the sensor sleeve checking that it

fits and is not too tight, the inner bore of

the sleeve must not be reduced in

diameter.

44.

Once sensor hole is cut and sensor has

been trial fitted, paint the raw metal edges

to prevent corrosion.

45.

Fit sensor sleeve into bar first as

shown, noting that the tab at rear is up

for RHS of bull bar and down for LHS

(the same orientation as original OE).

Then fit sensor into sleeve.

46.

Fit loom extensions and push anchor

plug into slot in wing brace

Note: Connections are always inboard.

Hint: Take care not to damage sensor

electrical connections when removing and

refitting.

Warning: Drilling operations can result in

flying metal debris, safety glasses should be