3 installing the air locker, Checking for assembly clearance – ARB RD119 User Manual

Page 14

3 Installing the Air Locker

12

3.4

Checking for Assembly Clearance

IMPORTANT:

Some third member castings will require modification for

correct Air Locker installation. A properly installed

Air Locker will have no less than 2mm [1/16”] between any

part of the differential carrier and the third member casting.

Reassemble the pinion shaft assembly using only 2 bolts finger

tight. (The pinion shaft assembly will be fully assembled later)

Hold the tapered roller bearing cups onto the cones on the carrier.

Carefully insert the carrier assembly into the third member so that

the ring gear is in mesh with the drive pinion.

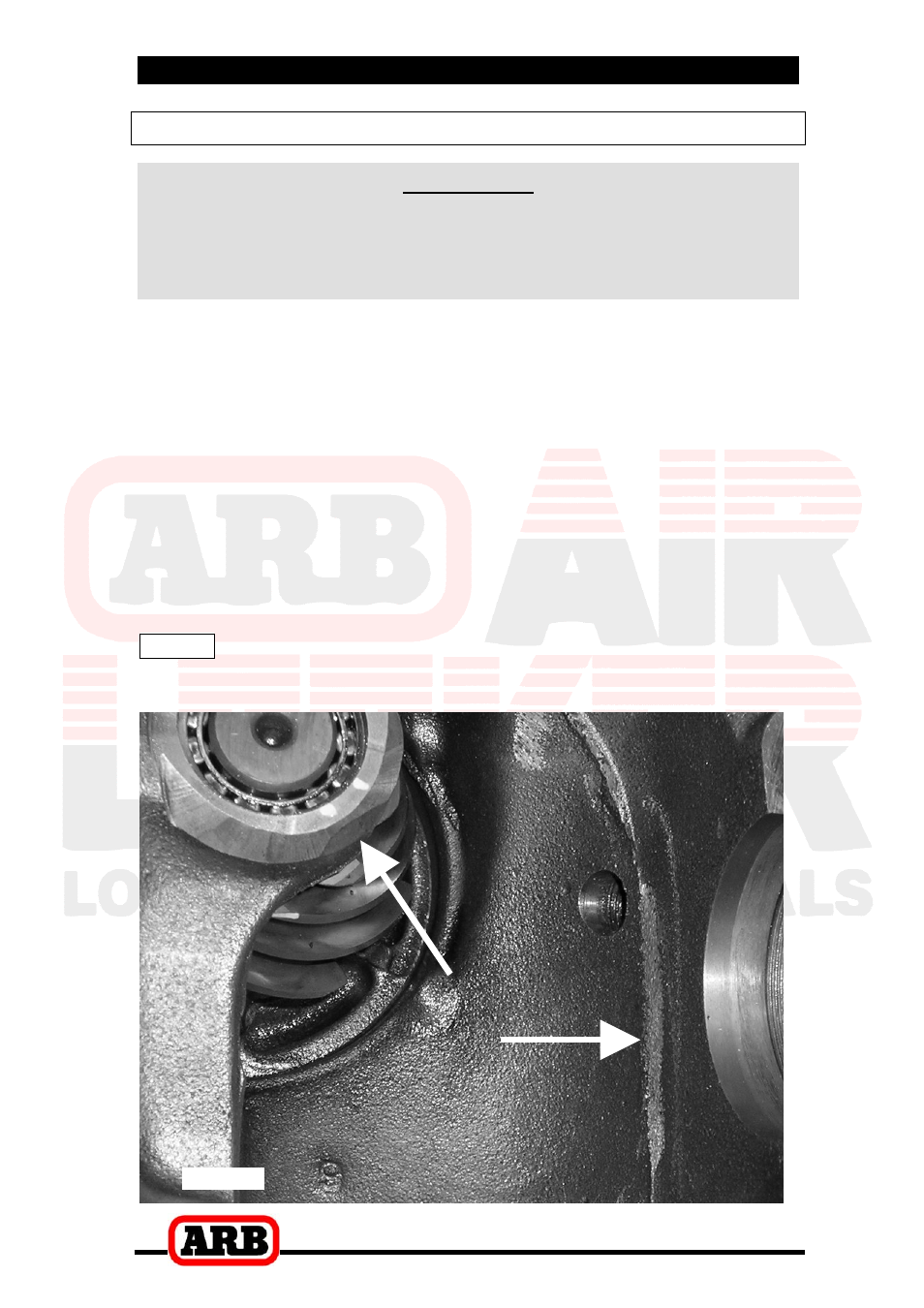

Using an automotive feeler gauge, check for adequate clearance

between the body of the Air Locker and the third member casting

around the pinion support bearing and behind the flange cap.

If necessary, remove the pinion shaft assembly and grind or file the

third member casting to gain clearance. Figure 5. shows an

example of relief grinding on the corner near the pinion support

bearing and along the casting flash line.

HINT :

Applying a machinists marking compound to the third

member casting surfaces will show any points of

contact after the Air Locker has been removed.

Figure 5.