Delivery valves – Hale SMR-U User Manual

Page 27

Section 14

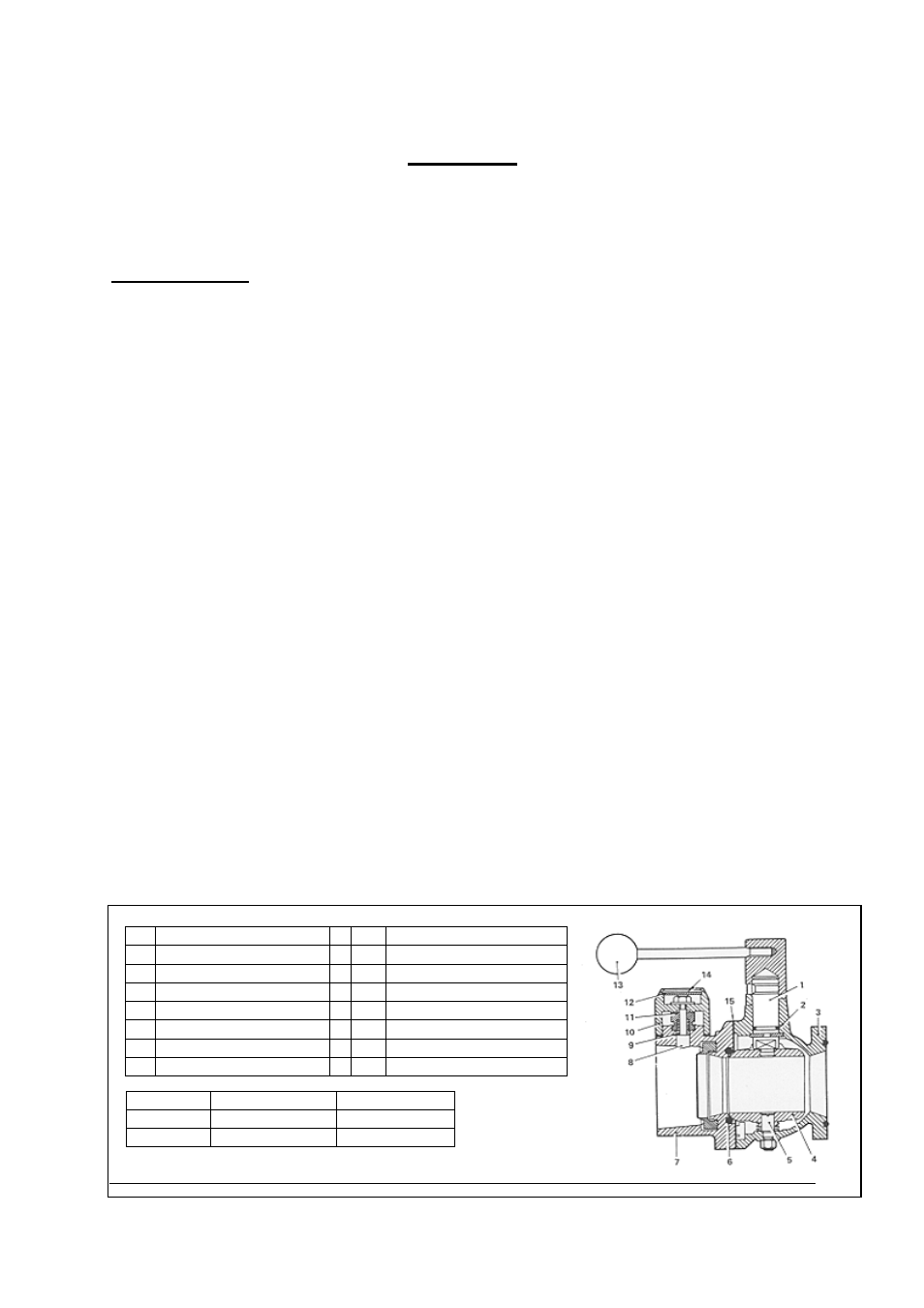

Delivery Valves

Ball Valve Type

The ball valve should not be dismantled unless it is functioning unsatisfactorily.

There are two possible faults and the method of correcting them is as follows:

1. Water leaking round the ball

This is due to the O Ring not pressing tightly enough against the ball. Remove the

bolts and spring washers and separate the coupling end tube from the ball valve

housing. Turn the O Ring over so that it presents a new face to the Ball Valve, or fit a

new O Ring. Rub a little Molybdenum Disulphide Powder into the surface of the ball

where it contacts the O Ring. Leave the original washers or the same thickness of

new washers, between the faces of the coupling end tube and the valve housing.

In the case of old valves which have seen extremely arduous service, it may be

necessary to fit a new ball, pivot or valve stem. To do this, remove the screw

securing the valve stem cap to the ball valve housing and lift off the handle

assembly.

Remove the nut on the underside of the valve housing and push the ball pivot pin

towards the centre of the ball. Remove the spring and take out the two half-rings

securing the valve stem. Push out the valve stem and withdraw the ball. Fit the new

part required and reassemble, reversing the above procedure. Use a right angled

screwdriver to hold the pivot pin when tightening the pivot pin nut. Ensure that the

handle is fitted in the correct position. Fit the stem O Ring and ensure that the two

half rings are correctly positioned.

2. Water leaking up the valve stem

If this occurs, remove the handle and stem as in "1" above and fit a new valve stem

O Ring, rubbing a little molybdenum Disulphide Powder into the bore of the valve

stem cap.

1 Valve

Stem

9 Spring

2 Valve Stem Seal

10 Coupling Release Cap

3 Valve Housing

11 Release Cam

4 Ball Valve

12 Closure Disc

5 Ball pivot and Spring

13 Operating Handle

6 O

Ring

14 Circlip

7 Coupling End Tube

15 Joint Washers

8 Coupling Release Bolt

©Godiva, Warwick

September 2000

wsmaint-Issue2 25-9-02

27

Part Nos Light Alloy I/C Gunmetal I/C

LH TH137 TH153/100

RH TH138

TH154/100