Step 14 — pumpdown & evacuation, Pump down – Bryant EVOLUTIONR EXTREME 280ANV User Manual

Page 11

11

0

50

100

150

200

250

300

350

400

0

10

20

30

40

50

60

Vapor Service

Valve Pressure

Suction Pressure

For use in Heating Charging Mode only

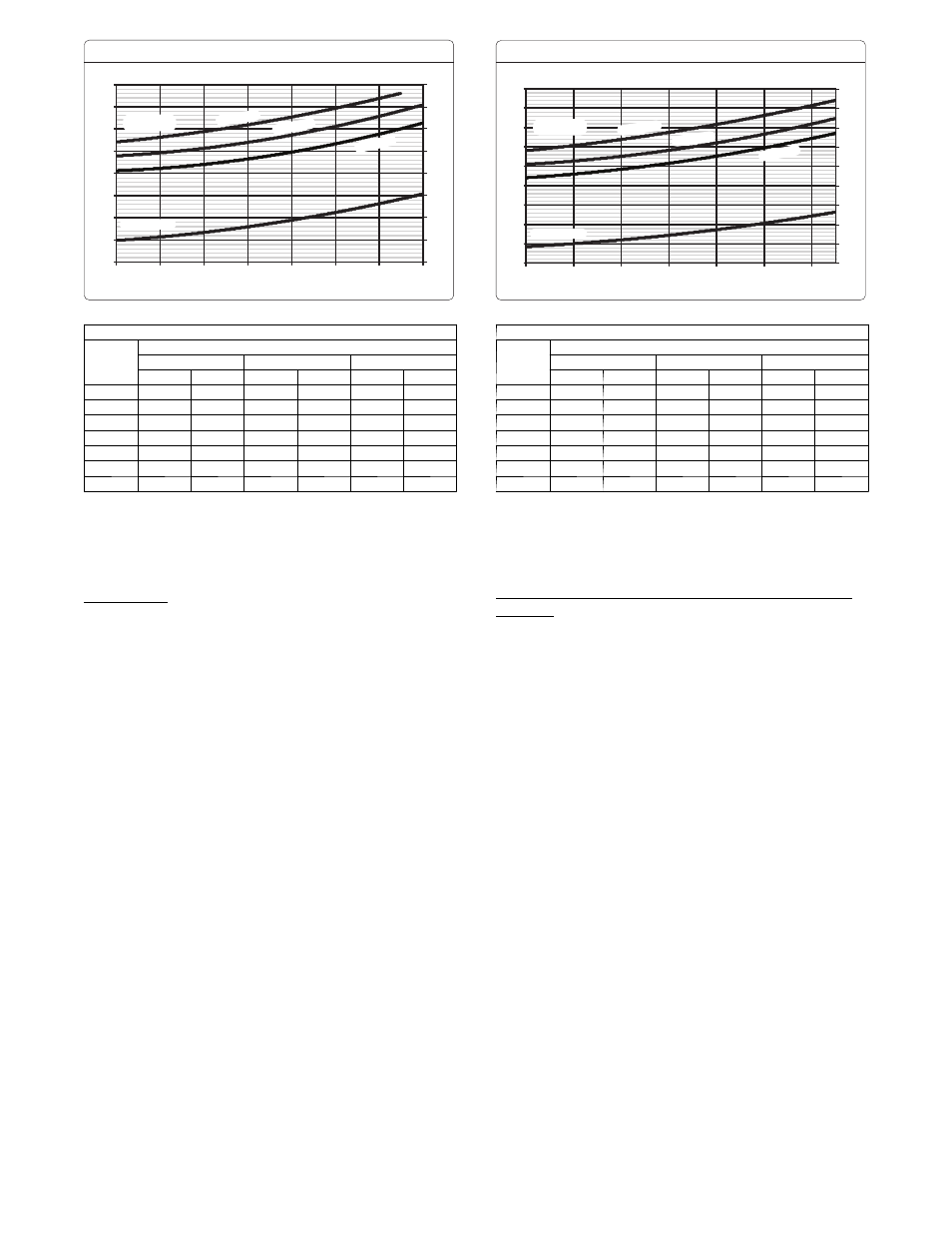

Heating Check Chart - 280ANV024/036

See user interface set in Charging Mode

Charging In Cooling Mode - 280ANV024/036

(-18ºC)

(-12ºC)

(-10ºC)

(-7ºC)

(4ºC)

(10ºC)

(16ºC)

Outdoor Ambient Temperature ºF (ºC)

Refrigerant Pressure (psig)

Refrigerant Pressure (KPa)

2757

2413

2068

1724

1380

1034

690

345

0

80ºF ID (27ºC)

70ºF ID (21ºC)

60ºF ID (16ºC)

A12045

280ANV024/036 Heating Pressure check Chart (Psig)

OD DB

(_F)

Indoor Temperature (_F)

60

70

80

High

Low

High

Low

High

Low

60

290

129

329

130

368

132

50

263

106

303

108

346

110

40

245

89

285

90

324

90

30

232

74

270

81

312

87

20

222

69

256

68

291

64

10

212

55

246

52

281

53

0

203

49

238

43

270

50

Fig. 12 -- Heating Pressure Check Chart 280ANV024/036

Heating Check Chart - 280ANV048/060

0

50

100

150

200

250

300

350

400

450

0

10

20

30

40

50

60

Vapor Service

Valve Pressure

Suction Pressure

Charging In Cooling Mode - 280ANV048/060

For use in Heating Charging Mode only

See user interface set in Charging Mode

80ºF ID (27ºC)

70ºF ID (21ºC)

60ºF ID (16ºC)

(-18ºC)

(-12ºC)

(-10ºC)

(-7ºC)

(4ºC)

(10ºC)

(16ºC)

Outdoor Ambient Temperature ºF (ºC)

Refrigerant Pressure (psig)

Refrigerant Pressure (KPa)

2757

2413

2068

1724

1380

1034

690

345

0

3102

A12046

280ANV048/060 Heating Pressure check Chart (Psig)

OD DB

(_F)

Indoor Temperature (_F)

60

70

80

High

Low

High

Low

High

Low

60

324

121

360

120

407

121

50

293

99

333

100

380

102

40

277

87

307

80

360

88

30

257

69

288

65

333

69

20

242

57

281

60

320

60

10

232

50

263

47

306

50

0

218

42

253

43

288

42

Fig. 13 -- Heating Pressure Check Chart 280ANV048/060

Step 14 — Pumpdown & Evacuation

If this system requires either a Pump Down or Evacuation for any

reason, the procedures below must be followed:

Pump Down

Because this system has an inverter controlled, compressor, suction

pressure transducer and EXV, conventional procedure cannot be

used to “pump down” and isolate the refrigerant into the outdoor

unit. The UI (User Interface) has provisions to assist in performing

this function.

1. Connect gages to 280ANV liquid and vapor or suction ca-

pillary service ports to monitor operating pressures during

and at completion of the procedure.

2. In the advanced menu of the UI, go to Checkout > Heat

Pump> Pumpdown

3. Select mode to pump down in (COOL or HEAT), COOL

mode allows refrigerant to be isolated in outdoor unit.

HEAT mode allows the refrigerant to be isolated in indoor

coil and lineset. Set desired time period. Default time peri-

od for the procedure is 120 minutes.

4. Select Start on UI to begin the pumpdown process. Unit

will begin running in selected mode after a brief delay.

5. Close the liquid service valve.

6. The unit will run in selected mode with the low pressure

protection set to indicate pumpdown is complete when the

suction pressure drops below 0 psig. Compressor protec-

tions are still active to prevent damage to the compressor or

inverter (high pressure, high current, high torque, scroll

temperature, etc.) .

7. Once system indicates pumpdown complete or failure to

complete shutdown, close vapor service valve.

8. If pumpdown does not complete due to compressor safety

shutdown, a recovery system will be required to remove fi-

nal quantity of refrigerant from indoor coil and line set.

9. Remove power from indoor and heat pump unit prior to ser-

vicing unit.

NOTE: A small quantity of charge remains in the OD unit that

must be manually recovered if isolating refrigerant to indoor coil

and lineset via HEAT mode PUMP DOWN.

Evacuation and Recovery of Refrigerant from within

280ANV

Because this system has an EXV for the heating expansion device,

additional steps must be taken to open the EXV if the heat pump

unit must be evacuated for service reasons. If the EXV is not open

when pulling a vacuum or recovering refrigerant from the heat

pump unit, extended evacuation time may be required and/or

inadequate vacuum obtained.

The UI (User Interface) has

provisions to open the EXV for refrigerant recovery and/or

evacuation.

1. Connect gages to 280ANV liquid and vapor or suction ca-

pillary service ports to monitor operating pressures during

and at completion of the procedure. Attach recovery system

or vacuum pump to gage set as needed for the service pro-

cedure. The service valves must be open to evacuate the

unit through the line set service ports. The suction capillary

service port is a direct connection to the suction port of the

compressor.

2. In the advanced menu of the UI, go to Checkout > Heat

Pump> > Evacuation.

3. Set desired time period. Default time period for the proced-

ure is 120 minutes.

4. Select START on UI to open the valve.

5. Begin evacuation or refrigerant recovery as required for the

procedure after UI indicates the EXV is open. Power may

be removed from heat pump after the UI indicates “READY

TO EVACUATE.”

6. Remove power from indoor and heat pump unit prior to ser-

vicing unit. The EXV will retain the open position.

NOTE: See service training materials for troubleshooting the

EXV using EXV CHECK mode.