Bush Hog 6045 User Manual

Page 52

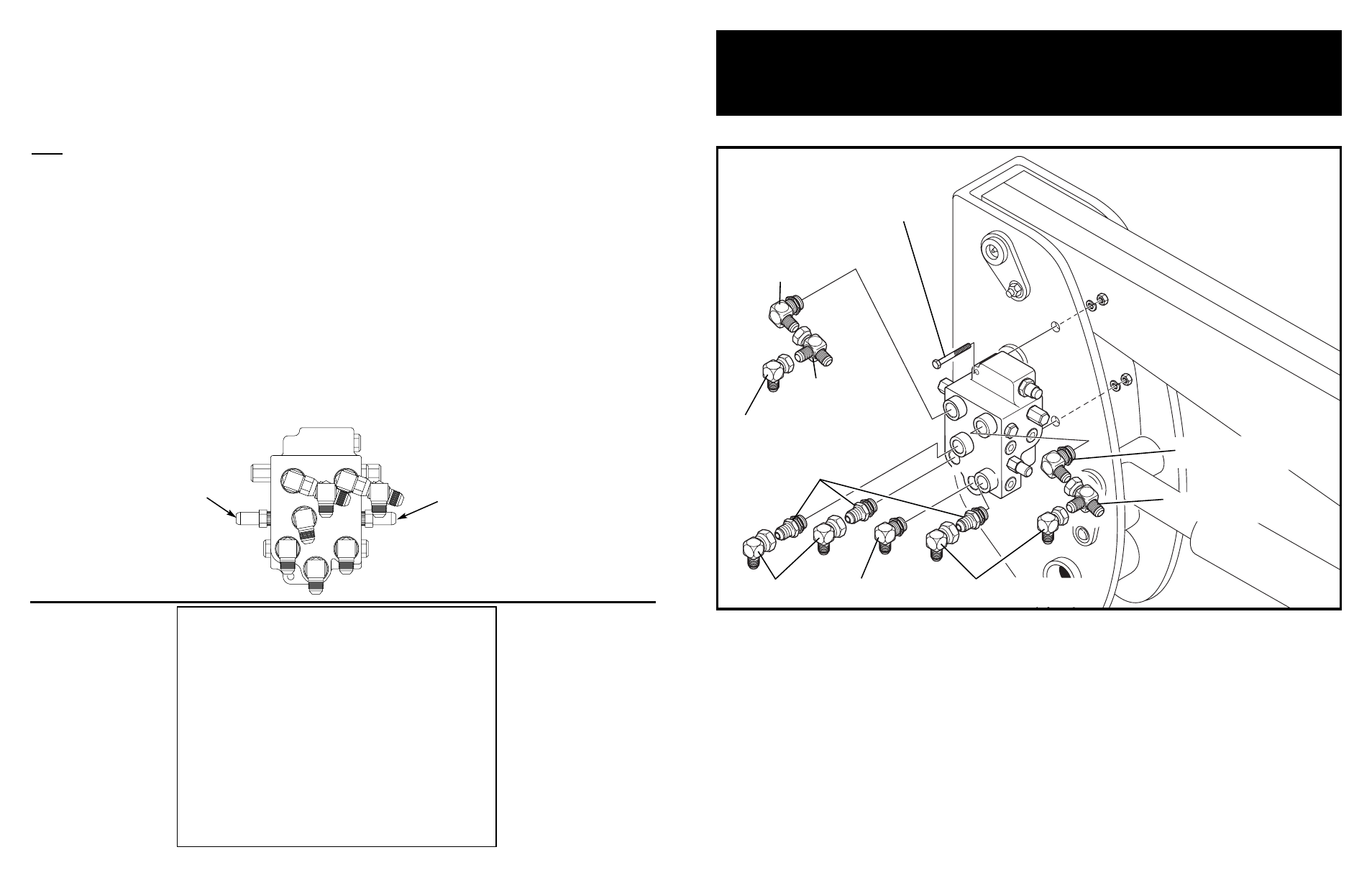

50051690 SELF LEVELING VALVE BUNDLE

MOUNTING INSTRUCTIONS

BUSH HOG 3545, 4045, 5045 & 6045 MID MOUNT FRONT END LOADERS

~ ASSEMBLY INSTRUCTIONS ~

1. Attach self leveling valve to the right hand pedestal using the (2) 5/16”- 2 1/2” Gr. 5 capscrews,

5/16” lockwashers and 5/16” hex nuts provided in kit.

2. In ports A, C, & D install a 7/8” ORB male - 3/4” JIC male straight thread adapter in each port. To

each straight adapter attach a 3/4” JIC female - 3/4” JIC male 90° elbow.

3. In ports B, E & F install a 7/8” ORB male - 3/4” JIC male 90° elbow into each port.

4. Install a 3/4” JIC female - 3/4” JIC male TEE to each of the 90° elbows in ports E & F with the single

leg pointing out. Install a 3/4” JIC female - 3/4” JIC male 90° elbow to each outward pointing leg of

TEE’s.

05/03/06

62-06

Instruction Sheet 50051610

A

B

C

D

E

F

(2) 5/16” x 2 1/2” capscrew Gr.5

(2) 5/16” lockwasher

(2) 5/16” hex nut

7/8” ORB male to 3/4” JIC

male 90° elbow

7/8” ORB male to 3/4”

JIC male 90° elbow

7/8” ORB male to

3/4” JIC male adapter

3/4” JIC female to 3/4”

JIC male 90° elbow

3/4” JIC female to 3/4”

JIC male 90° elbow

3/4” JIC female to 3/4”

JIC male TEE

DESCRIPTION

The hydraulic self-leveling option is designed to be incorporated into Bush Hog’s standard loader hydraulic circuit. A dual self-

level valve controls flow throughout the system so as to maintain a nearly constant position of the loader attachment relative

to the ground. The valve performs this function in both the raising and lowering mode. The bucket (or other attachment) may

be operated at any time, independent of the self-level valve, giving the operator the ability to reposition it throughout the work

cycle.

NOTE: IF THE LOADER ATTACHMENT ROLLS COMPLETELY BACK WHILE LOWERING THE BOOM, DOWNWARD

MOTION WILL CEASE; ROLL THE ATTACHMENT FORWARD TO CONTINUE LOWERING.

ADJUSTMENT

Since the same self-level valve is used on different Bush Hog loaders, adjustment of the valve may be required when installed

on one particular loader or the other to obtain a preferred performance. There are two separate adjustment screws, one for the

raising mode and one for the lowering mode. Remove the dust cap to access the adjustment screw and loosen the jam nut

prior to adjusting. Adjustments should be made in 1/4 turn increments to achieve the desired motion according to the following

logic:

RAISING:

Clockwise - More Rollback

Counterclockwise - More Dump

LOWERING:

Clockwise - More Dump

Counterclockwise - More Rollback

Being a “needle valve” type adjustment, a point is reached when backing the adjustment screw out further (counterclockwise)

has no effect. The maximum effective range of adjustment in this situation is approximately 2-3 turns.

Raising Adjustment

Lowering Adjustment

50051690 SELF LEVEL VALVE BUNDLE

PART NUMBER

QTY.

PART NAME

25H50700

4

HYDRAULIC HOSE 68”

25H49136

1

DUAL SELF LEVEL VALVE

50027314

1

BAG OF HARDWARE

50051610

1

INSTRUCTION SHEET

68822

1

CRATE

50027314 BAG OF HARDWARE

25H47571

5

NYLON CABLE TIES

25H43832

3

HYDRAULIC ADAPTER

25H43235

2

HYDRAULIC TEE

25H40576

5

HYDRAULIC ELBOW

25H40475

3

HYDRAULIC ELBOW

25H40043

4

HYDRAULIC ADAPTER

15528

2

HEX NUT 5/16’’

15808

2

LOCKWASHER 5/16’’

20504

2

CAPSCREW 5/16” X 2-1/2” GR.5

51260

1

BAG

3/4” JIC female to 3/4”

JIC male 90° elbow

7/8” ORB male to 3/4” JIC

male 90° elbow

3/4” JIC female to 3/4”

JIC male TEE