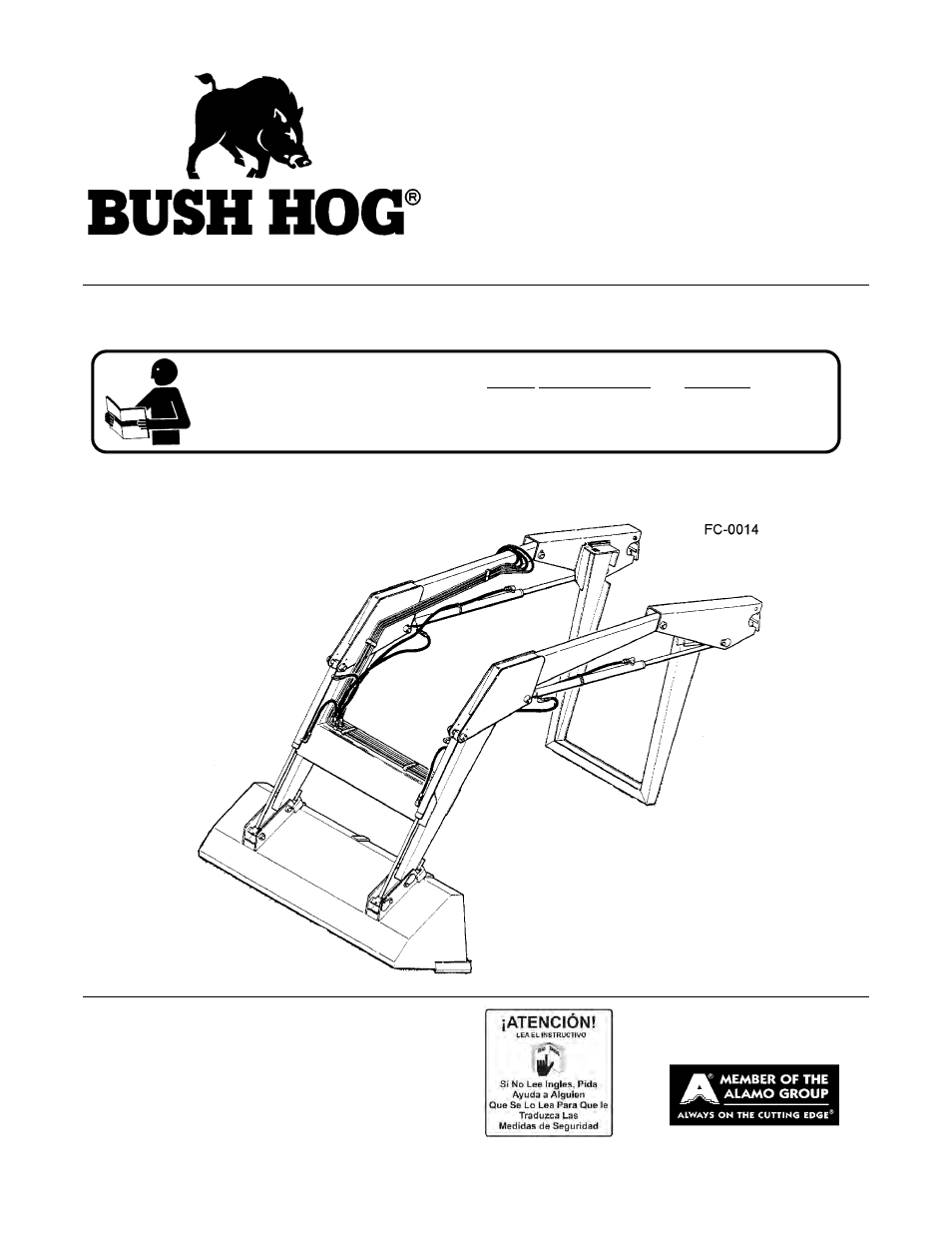

Bush Hog FC-0014 User Manual

Operator’s manual, Loader

© 2011 Alamo Group Inc.

$0.00

2647

Published 01/11

Part No.

50069206

OPERATOR’S MANUAL

BUSH HOG

®

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

LOADER

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

Table of contents

Document Outline

- 2647

- OPERATOR’S MANUAL

- To the Owner/Operator/Dealer

- TABLE OF CONTENTS

- General Safety Instructions and Practices

- Operator Safety Instructions and Practices

- Equipment Operation Safety Instructions and Practices

- Connecting or Disconnecting Implement Safety Instructions and Practices

- Transporting Safety Instructions and Practices

- Maintenance and Service Safety Instructions and Practices

- Storage and Parking Safety Instructions and Practices

- Concluding Safety Instructions and Practices

- Federal Laws and Regulations

- Assembly Instructions

- Proper Ballasting and Wheel Spacing

- Installing Mounting Brackets

- Installing Bucket

- Installing Bucket Level Indicator

- Dismounting and Mounting Loader

- Dismounting Loader

- 1. Locate tractor and loader on firm level ground.

- 2. Dump the bucket and lower it to the ground. Engage tractor brakes and shut off engine. Move lift control lever back and forth several times to relieve pressure on the lift cylinders.

- 3. Loosen bolts which clamp side frame uprights to the mid mounting assembly. Remove bolts, washers and nuts.

- 4. Remove rubber strap securing hoses to the right front mounting frame bracket.

- 5. Start tractor engine and release tractor brakes. Activate lift control lever to raise side frame uprights off of the midmounting assembly. Continue activating the lift control lever while slowly backing tractor up. Allow the loader to slide on the...

- 6. Move lift and bucket control levers back and forth several times to relieve pressure on the lift and bucket cylinders. Disconnect quick couplers between loader and tractor. Hang hoses over the side frame for storage. If equipped with optional auxi...

- 7. Fasten bolts, washers and nuts onto hinge for storage.

- 8. Start tractor engine, release tractor brakes and slowly back the tractor away from the loader.

- Mounting Loader

- 1. Slowly drive tractor up to loader until the hoses will reach loader to the tractor. Engage tractor brakes and shut off tractor engine.

- 2. Connect quick couplers between tractor and loader. If equipped with optional 1-lever valve, reinstall valve support assembly back into the valve support guide tube also.

- 3. Remove bolts, washers and nuts from hinge.

- 4. Start tractor engine and release tractor brakes. Slowly drive tractor ahead while activating lift cylinder control lever to allow the front brackets to engage the side frames through the notches in lower flange. Continue sliding the loader on the ...

- 5. Clamp hinge assembly of upright around tube of midmount assembly. Install bolts, washers and nuts, and securely tighten.

- Dismounting Loader

- Quick Attach Device (Optional)

- 1. Be sure both quick hitch pin levers are in the unlocked position, with the levers pointing up. Tilt the loader quick hitch forward, drive the loader into the attachment bracket and engage top of the quick hitch into the top of the attachment bracket.

- 2. Raise the loader slightly and rotate the top of the quick hitch back toward the operator until the bottom of the attachment is seated firmly in the bottom of the quick hitch.

- 3. Rotate the quick hitch pin levers down 90 degrees to the locked position. You should feel a firm resistance when locking the levers down. The tapered pins must extend through the slots in the bottom of the attachment bracket. The tapered side of t...

- 4. Raise the loader and attachment to shoulder height. By standing at the side of the loader, inspect the connection between the quick hitch and attachment.

- 5. On level ground, tilt the attachment down 90 degrees and lower it to the ground. Lower the loader further to slightly raise the front of the tractor of the tractor off the ground. Drive the tractor in reverse while the attachment is on the ground ...

- OPERATION SECTION

- Bush Hog 2647 LOADER

- OPERATION INSTRUCTIONS

- 1. Standard Equipment and Specifications

- 2. Operator Requirements

- 2.1 Tractor Requirements

- 2.2 ROPS and Seat Belt

- 2.3 Tractor Lighting and SMV Emblem

- 2.4 Tractor Ballast

- 3. Getting On and Off the Tractor

- 5. Pre-Operation Inspection and Service

- 7. Operating the Tractor and Loader

- 9. Transporting the Tractor and Implement

- 9.1 Transporting on Public Roadways

- 10. TROUBLESHOOTING GUIDE

- Loader slow or will not lift Hydraulic oil too heavy. Change to proper oil.

- and/or dump

- Oil filter plugged. Clean or replace filter.

- Hydraulic pump worn. Repair or replace pump.

- Oil line restricted or leaking. Check all hoses and tubes for leaks,

- damage or restrictions. Replace

- damaged or restricted hoses or tube

- oil lines.

- Control valve does not shift Inspect, clean, repair or replace

- properly. valve.

- Air in hydraulic system. Cycle lift cylinders and bucket

- cylinders several times to free

- system of air.

- Cylinder leaks internally. Replace seals.

- Faulty relief valve (tractor). Clean and replace relief valve.

- Loader chatters or Air leak in pump inlet line. Check, tighten or replace inlet line.

- vibrates when raising

- or lowering

- Air in hydraulic system. Cycle lift and bucket cylinders.

- Oil level too low. Add oil as required.

- Oil leakage Loose connections. Tighten fittings.

- Defective fittings or hoses. Replace defective parts.

- Worn or damaged o-ring or Install a seal repair kit.

- wiper seal in cylinder rod end. See “Cylinder Service”.

- Worn or damaged or rings in Install an o-ring repair kit.

- valve.

- Insufficient lift capacity Load is greater than boom Check loader specifications.

- lift capacity.

- Improper hydraulic pump Repair or replace pump.

- operation.

- Internal lift cylinder leakage. Replace any worn parts and install

- a seal repair kit. See “Cylinder Service”.

- Improper hydraulic valve Repair or replace valve.

- operation.

- TROUBLE POSSIBLE CAUSE POSSIBLE REMEDY

- Excessive wear on Bucket is riding on cutting Use boom “FLOAT” position or

- cutting edge edge instead of wear runners. bucket level indicator to ensure

- bucket rides on wear runners.

- Bucket cutting edge Rear axle on tractor not level With tractor on level surface,

- not flat on the ground. from side to side. compare rear axle height from left

- to right, measuring from axle center to ground. Adjust air pressure in rear tires until axle height measures the same for both sides.

- MAINTENANCE SECTION

- Lubrication Schedule

- Daily Maintenance

- 1. Check fluid level of tractor hydraulic system before starting each day’s operation. If necessary, add hydraulic oil as recommended in your tractor operator’s manual.

- 2. After every ten hours of operation, lubricate all twelve grease fittings; one at each end of lift boom arms and one at rod and base ends of each lift and bucket cylinder.

- 3. After every ten hours of operation, check all hardware and tighten where required.

- 4. Replace hoses immediately if they are damaged by a cut or scrape, extruded at the fittings or leaking. Hydraulic oil leaks should be repaired promptly to avoid loss of oil and serious personal injury from escaping oil.

- Hydraulic Pressure Check

- 1. Obtain a pressure gauge that measures 3000 PSI in 50 PSI increments.

- 2. Install gauge into the hydraulic line connecting the loader valve and to the base port of bucket cylinders.

- 3. Start engine and adjust to 1700-2200 RPM.

- 4. Push bucket control lever to pressurize the hydraulic line with the gauge attached. Hold the control until the cylinders reach the fully extended position. Holding the control with cylinders fully extended will give you the hydraulic system pressu...

- 5. If pressure is not correct, refer to “TROUBLESHOOTING” Section for possible remedy or contact your dealer.

- Cylinder Service

- Lift Cylinder Disassembly

- 1. Hold cylinder tube (11) stationary and rotate cylinder head (5) to thread the wire retaining ring (12) out of the slot in the cylinder tube.

- 2. Pull shaft (1), with all assembled parts, out of cylinder tube (11).

- 3. Remove 3/4 elastic lock nut (10) from end of shaft and slide cylinder piston (8) and cylinder head (5) off the shaft.

- 4. Remove piston wear ring (9), piston seal (8), and o-ring (7) from outside grooves on piston(6).

- 5. Remove wiper seal (2), rod seal (3) and wear ring (5) from inside of cylinder head and o-ring (4) from groove on outside of head.

- 6. Clean all parts including cylinder tube, in a suitable cleaning solvent, then use air pressure to blow any dirt or excess solvent from all parts.

- 7. Examine all parts for wear or damage and replace, if necessary.

- Lift Cylinder Reassembly

- 1. Place o-ring part of rod seal (3) into groove inside of head (5) and position it against the side of the groove toward the cylinder tube end.

- 2. Press one side of the L-seal part of the rod seal (3) past its center until it touches the opposite side, then press the two ends of this shape together as necessary to fit into the bore of the cylinder head. With the seal compressed in this manne...

- 3. Install wiper seal (2) with lip of seal facing out and flush with top of cylinder head (5).

- 4. Place o-ring (4) in groove on outside of head (5).

- 5. Remove sharp edges on outer edge of the threaded end of shaft (1). Lubricate wiper seal (2) and rod seal (3) in head and carefully slide head (5) onto shaft.

- 6. Place o-ring (10), piston seal (11) and piston wear ring (8) in grooves on outside of piston (9).

- 7. Slide piston (6) onto threaded end of shaft and install 3/4 elastic lock nut (10) to 100 lbs.

- 8. Lubricate piston wear ring (9) and piston seal (8) on piston (6), o-ring (4) on head (5), then carefully slide piston and head into cylinder tube (11).

- 9. Insert wire retaining ring (12) into slot in the cylinder tube and turn cylinder head while applying pressure to wire ring to thread it into the groove.

- Bucket Cylinder Disassembly

- 1. Hold cylinder tube (15) stationary and rotate cylinder head (6) so beveled end of wire ring (14) will thread out through slot. (Image Mnt-L- 0031)

- 2. Pull shaft (1) with all assembled parts out of cylinder tube (15).

- 3. Remove 3/4 elastic lock nut (13) from end of shaft and slide cylinder piston (9), and cylinder head (6) off the shaft.

- 4. Remove piston wear ring (12), piston seal (11) and o-ring (10) from outside grooves of piston (9).

- 5. Remove wiper seal (2), snap ring (3), reinforcing washer (4), v-pack set (5) from inside of cylinder head and o-ring (8) and back- up washer 97) from groove on outside of head.

- 6. Clean all parts, including cylinder tube, in a suitable cleaning solvent, then use air pressure to blow any dirt or excess solvent from all parts.

- Bucket Cylinder Reassembly

- 1. Place new v-pack set (5) in head (6).

- 2. Place reinforcement washer (4) on top of v-pack set (5) and force down below snap ring groove.

- 3. Install snap ring (3) into snap ring groove.

- 4. Install wiper seal (2) with lip of seal facing out and flush with top of cylinder head (6).

- 5. Place back-up washer (7) and o-ring (8) in groove on outside of head (6).

- 6. Remove sharp edges on outer edge of threaded end of shaft (1). Lubricate wiper seal (2) and v-packing (5) in head and carefully slide head (6) onto shaft.

- 7. Place o-ring (10), piston seal (11) and piston wear ring (12) in grooves on outside of piston (9).

- 8. Slide piston (9) onto threaded end of shaft and install 3/4 elastic lock nut (13) to 300 ft./lbs.

- 9. Lubricate piston wear ring (12) and piston seal (11) on piston (9) and o-ring (8) on head (6) and carefully slide piston and head into cylinder tube (15).

- 10. Turn cylinder head (6) until hole in wire ring groove appears in slot in cylinder tube (15). Insert hook end of wire ring (14) into hole and turn cylinder head to thread wire ring into groove.

- Storage

- 1. Locate tractor and loader on firm level ground.

- 2. Dump the bucket and lower it to the ground. Engage tractor brakes and shut off engine. Move lift control lever back and forth several times to relieve pressure on the lift cylinders.

- 3. Loosen bolts which clamp side frame uprights to the mid mounting assembly. Remove bolts, washers and nuts.

- 4. Remove rubber strap securing hoses to the right front mounting frame bracket.

- 5. Start tractor engine and release tractor brakes. Activate lift control lever to raise side frame uprights off of the midmounting assembly. Continue activating the lift control lever while slowly backing tractor up. Allow the loader to slide on the...

- 6. Move lift and bucket control levers back and forth several times to relieve pressure on the lift and bucket cylinders. Disconnect quick couplers between loader and tractor. Hang hoses over the side frame for storage. If equipped with optional auxi...

- 7. Fasten bolts, washers and nuts onto hinge for storage.

- 8. Start tractor engine, release tractor brakes and slowly back the tractor away from the loader.

- 9. Clean dirt and debris from loader. Dirt will hold moisture and cause rust.

- 10. If loader is to be stored for an extended period of time perform lubrication procedure. Also apply a coat of heavy grease to exposed cylinder rods to prevent rusting.

- Lift Cylinder Disassembly

- Proper Torque for Fasteners

- TO THE OWNER/OPERATOR/DEALER

- LIMITED WARRANTY

- DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

- THIS LIMITED WARRANTY SHALL NOT APPLY:

- 1. To vendor items which carry their own warranties, such as engines, tires, and tubes.

- 2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

- 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgement of Bush Hog such use affects its performance, stability or reliability.

- 4. If the unit has been altered or repaired outside of an authorized Bush Hog dealership in a manner which, in the sole judgement of Bush Hog, affects its performance, stability or reliability.

- 5. To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid, worn blades, or to normal deterioration of such things as belts and exterior finish due to use or exposure.

- 6. To expendable or wear items such as teeth, chains, sprockets, belts, springs and any other items that in the company’s sole judgement is a wear item.

- 2647 LOADER

- Safety Section Page 17.pdf

- Concluding Safety Instructions and Practices

- Decal Location

- 1 26871 1 WARNING To Prevent Instability

- 2 7794 1 CAUTION Loader Safety Guides

- 3 50069077 2 MODEL 2647

- 4 36932 1 WARNING Avoid Injury During Installation

- 5 50057411 2 LOGO Bush Hog 3.2” x 14.50”

- 6 35674-6 1 STRIPE Silver, 13.5 ft.

- 7 48921 1 DANGER Stability Danger

- 8 48858 1 DANGER Electric Shock Danger

- 9 00776031 1 _________ Canister, Operator’s Manual

- 10 55580 1 _________ Sheet, Decal; includes two D516 Decals (Note: For Optional Quick Attach Device Only

- 11 50057413 1 LOGO Bush Hog 4.25” x 19.316”

- Decal Location

- Concluding Safety Instructions and Practices