Liebherr LTM 1200-5.1 User Manual

Page 4

PN 1200-5.1_D-GB/F/I/ESP/RUS 03.07.2007 10:09 Uhr Seite 4

Probedruck

C

M

Y

CM

MY

CY CMY

K

9

4

LTM 1200-5.1

LTM 1200-5.1

700

LSB -

LSB -

LSB -

CAN -

SCI -

• Variable supporting basis

Outriggers retracted

Supporting basis 5.5 m x 8.9 m

Supporting basis 8.3 m x 8.9 m

• Fix-mounted supporting pads with splash guard

• Travel of supporting ram of up to 700 mm

• Level control of the outriggers, all-automatic levelling of the

crane during the supporting procedure by "push-button"

• 2 x 9° lateral inclination of crane and crane superstructure

• Control panels at either side of the carrier with membrane

keyboard and electronic inclination indicator, push-buttons

for ENGINE/START/STOP and speed control are illuminated

and lockable

• Operation of the outrigger system in accordance with the

rules for the prevention of accidents

• Illumination of the supporting area by 4 incorporated

projectors

Setting crane on outriggers –

quick, convenient and safe

• Modern, comfortable driver’s cab of high functionality and

convincing design, corrosion resistant, sheet steel version,

cataphoretic dip-primed, front mounted on rubber shock

absorbers, rear cushioned hydraulically, internal sound and

heat absorbing panelling

• Safety glass all-round, greenish tinted front and side windows

for heat absorption, electric window lifters

• Arrangement of the control elements and displays according

to ergonomical aspects for safe and convenient handling

during continuous operation

• Digital display and keyboard units interconnected with the

functional blocks by data bus technology

• Driver’s seat cushioned pneumatically, with pneumatic lumber

support, headrest

• Steering wheel adjustable in height and inclination

• Heatable and electrically adjustable rear mirrors

• Safety belts for driver and co-driver

• 3 windscreen wipers with automatic wipe/wash system and

intermittent control

• Delayed switch-off of the interior lights

• Various racks and stackers

• Radio preparation

Comfortable driver’s cab of

high functionality

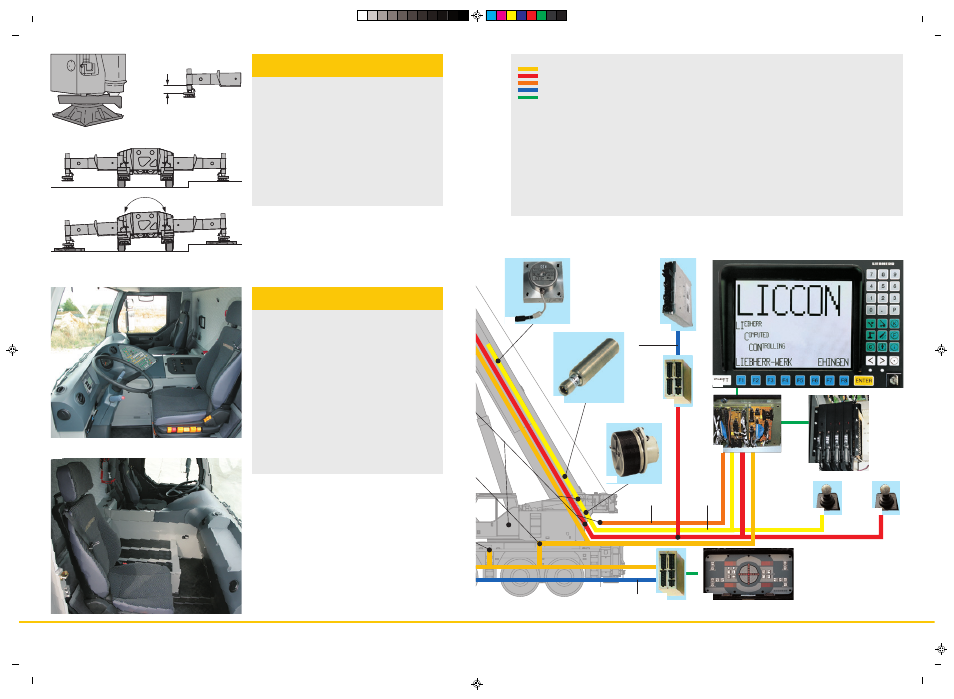

Legend:

LSB - Liebherr system bus 1

LSB - Liebherr system bus 2

LSB - Liebherr system bus 3

CAN - Busses

SCI - Serial Communication Interface

1 Input/output module for control of the suspension, Liebherr

Diesel engine, automatic transmission, control functions,

pneumatic control of brake functions

1a Instruments keyboard unit in driver’s cab

2 Input/output module for differential locks, display functions

2a Instruments keyboard unit in driver’s cab

3 Input/output module for outrigger system - right

3a Control unit for outrigger system - right

4 Input/output module for outrigger system - left

4a Control unit for outriggers system - left

5 Input/output module for engine brake, cruise controller, speed

setter, electronic control of Diesel engine (steering column

switch right) and automatic transmission

6 Control of Liebherr Diesel engine/carrier and automatic

transmission

7 Inclination sensor for automatic levelling

8 Slewing sensor in slipring unit

9 Connection of Liebherr system bus (LSB 1, 2, 3, 4)

10 LICCON central unit

11 LICCON monitor in crane cab

12 Length sensor and cable drum/energy cable for interlocking

gripper/telescopic boom

13 Inductive sensors (12 x)

14 Angle sensor on base section

15 Cable drum for items 16, 17, 18 and for luffing jib

16 Wind sensor

17 Hoist limit switch

18 Angle sensor

19 Input/output module for electronic control of Diesel

engine/superstructure, air flap, ventilator clutch, exhaust flap

20 Control injection pump – Liebherr Diesel engine/superstructure

21 Control lever

22 Pressure sensor (4 x) for output management and LMB (safe

load indicator)

23 Steering valve for active rear-axle steering

LSB 2

CAN-Bus

9

20

21

21

12

14

19

11

10

13

4

CAN-Bus

LSB 4

4a